A kind of high-strength green environmental protection paper and its preparation method and application

A green and high-strength technology, which is applied in papermaking, paper, packaging paper, etc., can solve the problems affecting the biocompatibility of bamboo fiber, and achieve the effect of improving bonding performance and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

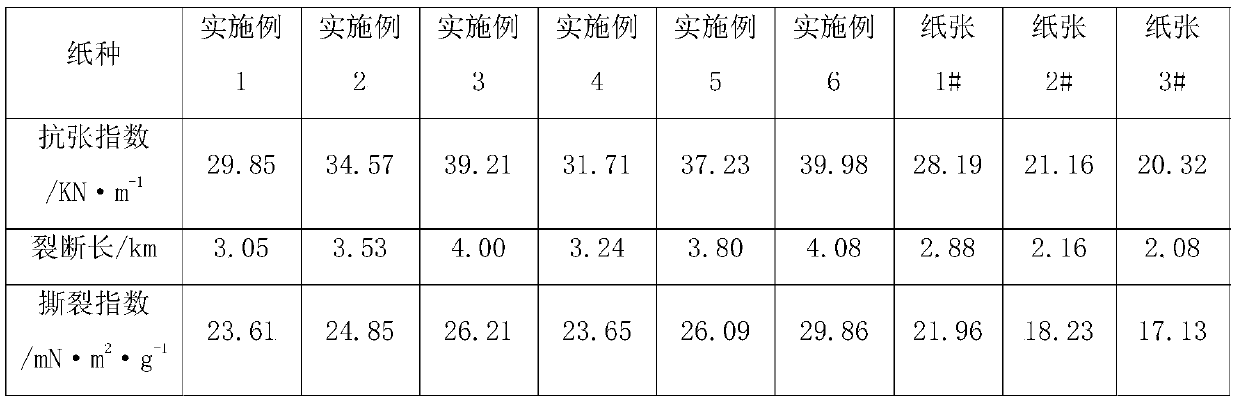

Examples

Embodiment 1

[0027] A preparation method for high-strength green environmental protection paper, comprising the following steps:

[0028] (1) the bamboo pulp raw material that 300g pulp is thick is 10% is placed in the beating of PFI mill, obtains the bamboo pulp that beating degree is 30 ° of SR;

[0029] (2) take by weighing the bamboo pulp that obtains in a certain amount of step (1) and add concentration and be in the cationic guar gum solution of 0.5wt%, the absolute dry mass of bamboo pulp is the 6wt% of cationic guar gum solution quality, at 25 ℃ Under conditions, after insulation 20min, take out bamboo pulp, wash 3 times with the distilled water of 3000ml, obtain the bamboo pulp after the pretreatment used in the experiment;

[0030] (3) the bamboo pulp after the pretreatment in step (2) and the PLA fiber that the cationic guar gum solution is not processed are on the paper machine according to 80g / m with the absolute dry mass ratio of 7:3 2 Quantitative papermaking can be done to...

Embodiment 2

[0032] A preparation method for high-strength green environmental protection paper, comprising the following steps:

[0033] (1) the bamboo pulp raw material that 300g pulp concentration is 10% is placed in the beating of PFI mill, obtains the bamboo pulp that beating degree is 40 ° of SR;

[0034] (2) take by weighing the bamboo pulp that obtains in a certain amount of step (1) and add concentration and be in the cationic guar gum solution of 1wt%, the absolute dry mass of bamboo pulp is the 8wt% of cationic guar gum solution quality, at 30 DEG C of conditions Next, after being kept warm for 25min, take out the bamboo pulp, wash 3 times with the distilled water of 3000ml, obtain the bamboo pulp after the pretreatment used in the experiment;

[0035] (3) the bamboo pulp after the pretreatment in step (2) and the PLA fiber that the cationic guar gum solution is not processed are on the paper machine according to 100g / m with the absolute dry mass ratio of 7:3 2 Quantitative pap...

Embodiment 3

[0037] A preparation method for high-strength green environmental protection paper, comprising the following steps:

[0038] (1) the bamboo pulp raw material that 300g pulp is thick is 10% is placed in the beating of PFI mill, obtains the bamboo pulp that beating degree is 50 ° of SR;

[0039] (2) take by weighing the bamboo pulp that obtains in a certain amount of step (1) and add concentration and be in the cationic guar gum solution of 1.5wt%, the absolute dry mass of bamboo pulp is the 10wt% of cationic guar gum solution quality, at 35 ℃ Under the condition, after being incubated for 30min, take out the bamboo pulp, wash 3 times with the distilled water of 3000ml, obtain the bamboo pulp after the pretreatment used in the experiment;

[0040] (3) with the bamboo pulp after the pretreatment in step (2) and the PLA fiber that the cationic guar gum solution is not processed with the absolute dry mass ratio of 7:3, on paper machine according to 120g / m 2 Quantitative papermakin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com