Flame-retardant wear-resistant polycarbonate material and manufacturing method thereof

A polycarbonate and wollastonite fiber technology, applied in the field of polymer materials, can solve the problems of insufficient flame retardancy and wear resistance of polycarbonate materials, and achieve increased surface chemical energy, increased surface roughness, and increased ratio The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

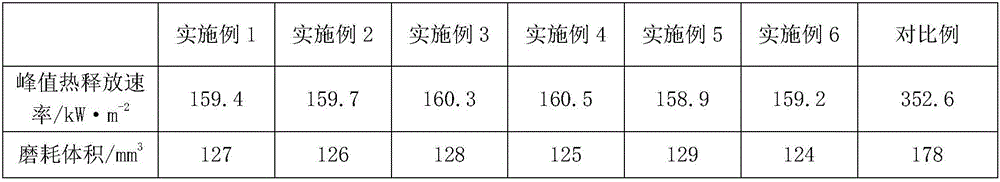

Examples

Embodiment 1

[0027] Flame-retardant and wear-resistant polycarbonate material, which is made of the following components by weight: 100 parts of bisphenol A polycarbonate, 0.8 parts of UV-326, 2,5-di-tert-butylhydroquinone 0.6 parts, ABS-g-MAH 5.5 parts, stearic acid 0.9 parts, silicone oil 0.6 parts, tributyl citrate 1 part, MBS 3 parts, silicone wax 3 parts, modified composite wollastonite fiber 19 parts.

[0028] Its manufacturing method comprises the following steps:

[0029] (1) Add magnesium hydroxide to deionized water, stir until it is uniform to obtain a magnesium hydroxide solution, put the magnesium hydroxide solution in a carbonization reactor, start stirring, add EDTA, wollastonite fiber, and feed carbon dioxide gas to Stop stirring when the pH value of the system is 7, naturally cool the product to room temperature and filter it with suction, put the filter cake in an oven and dry it at 100°C for 4 hours, transfer it to a Raymond mill and disperse it to obtain composite wolla...

Embodiment 2

[0034] Flame-retardant and wear-resistant polycarbonate material, which is made of the following components by weight: 100 parts of bisphenol A polycarbonate, 0.6 parts of UV-326, 2,5-di-tert-butylhydroquinone 0.8 parts, ABS-g-MAH 5 parts, stearic acid 1.1 parts, silicone oil 0.4 parts, tributyl citrate 3 parts, MBS 5 parts, silicone wax 3.2 parts, modified composite wollastonite fiber 21 parts.

[0035] The manufacture method of this polycarbonate material is the same as embodiment 1.

Embodiment 3

[0037] Flame-retardant and wear-resistant polycarbonate material, which is made of the following components by weight: 100 parts of bisphenol A polycarbonate, 0.4 parts of UV-326, 2,5-di-tert-butylhydroquinone 1 part, 6.5 parts of ABS-g-MAH, 0.7 parts of stearic acid, 0.2 parts of silicone oil, 5 parts of tributyl citrate, 7 parts of MBS, 3.4 parts of silicone wax, 20 parts of modified composite wollastonite fiber.

[0038] The manufacture method of this polycarbonate material is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com