Method for directly growing nickel oxide and cobalt oxide and complex energy storage material thereof on titanium substrate

A technology of energy storage materials and titanium substrates, applied in metal material coating technology, electrolytic coating, liquid chemical plating, etc., can solve the problems of high precision requirements, complex experimental conditions, poor cycle performance, etc., and achieve precision The effect of low requirements, superior energy storage performance, and simple experimental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

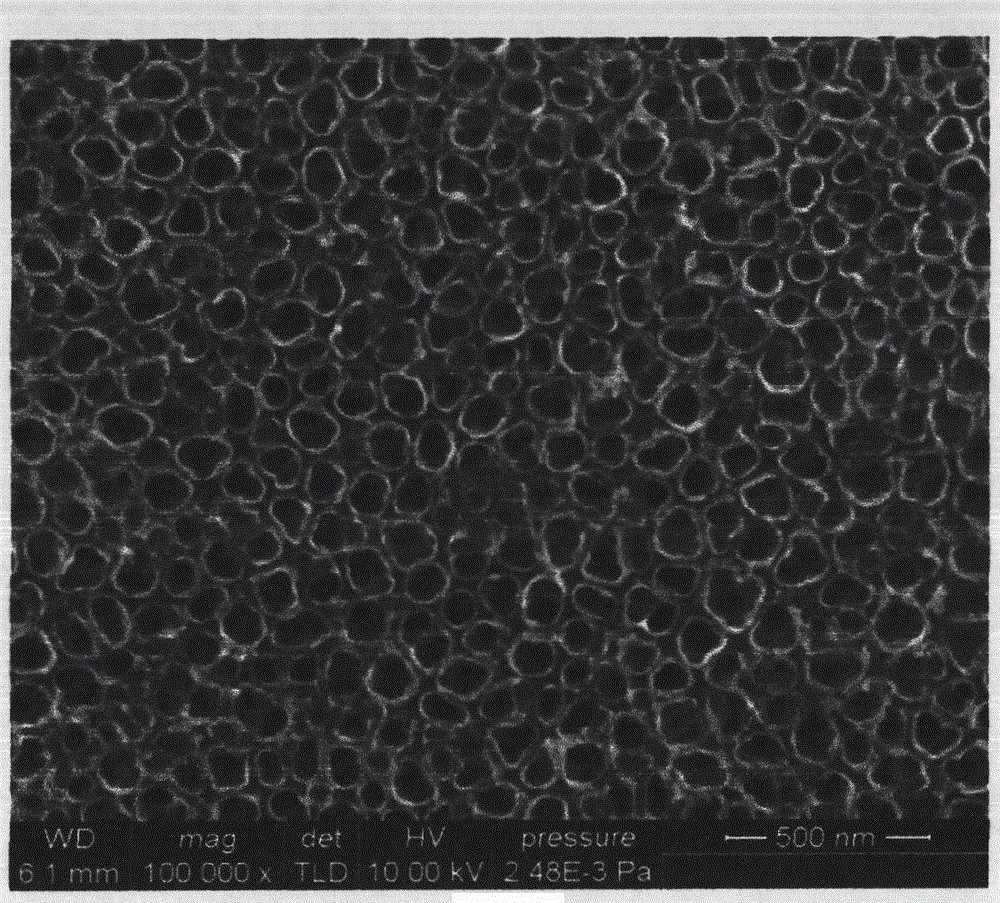

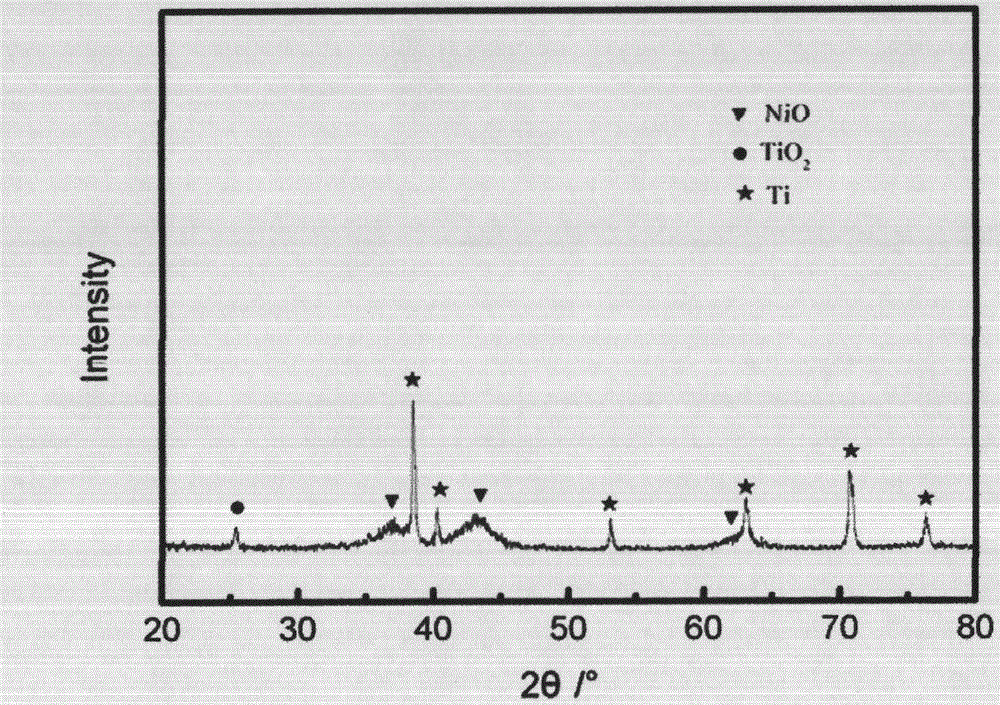

[0030] A method for directly growing a NiO nanowire film on a titanium substrate, comprising the following steps:

[0031] a. Treatment of titanium substrate: ultrasonically clean the titanium sheet in dilute hydrochloric acid, absolute ethanol and deionized water for 5-10 minutes respectively, use the cleaned and dried titanium sheet as the anode, and place the platinum sheet as the cathode in 0.05-0.5mol / L of HF solution, react at room temperature for 1.0h at a voltage of 10-30V, and prepare TiO on the surface of the titanium substrate. 2 NT, and then the resulting TiO 2 NT was calcined in a nitrogen atmosphere for 3h at a temperature of 400-500°C to improve the TiO 2 Conductivity of NT;

[0032] b. Soak the titanium sheet treated in step a in citric acid solution (PH=1.5) for 12-24 hours.

[0033] c. Ni salt solution: dissolve a certain amount of nickel nitrate hexahydrate in deionized water, stir for 10 minutes, and prepare a nickel nitrate solution of 0.02mol / L~0.08mo...

Embodiment 2

[0039] A method for directly growing a CoO nanorod film on a metal titanium substrate, comprising the following steps:

[0040] a. Treatment of titanium substrate: ultrasonically clean the titanium sheet in dilute hydrochloric acid, absolute ethanol and deionized water for 5-10 minutes respectively, use the cleaned and dried titanium sheet as the anode, and place the platinum sheet as the cathode in 0.05-0.5mol / L of HF solution, react at room temperature for 1.0h at a voltage of 10-30V, and prepare TiO on the surface of the titanium substrate. 2 NT, and then the resulting TiO2 NT was calcined in a nitrogen atmosphere for 3h at a temperature of 400-500°C to improve the TiO 2 Conductivity of NT;

[0041] b. Soak the titanium substrate treated in step a in a citric acid solution (PH=1.5) for 12-24 hours.

[0042] c. Co salt solution: dissolve a certain amount of cobalt nitrate hexahydrate in deionized water, stir for 10 minutes, and prepare 0.02mol / L~0.08mol / L cobalt nitrate s...

Embodiment 3

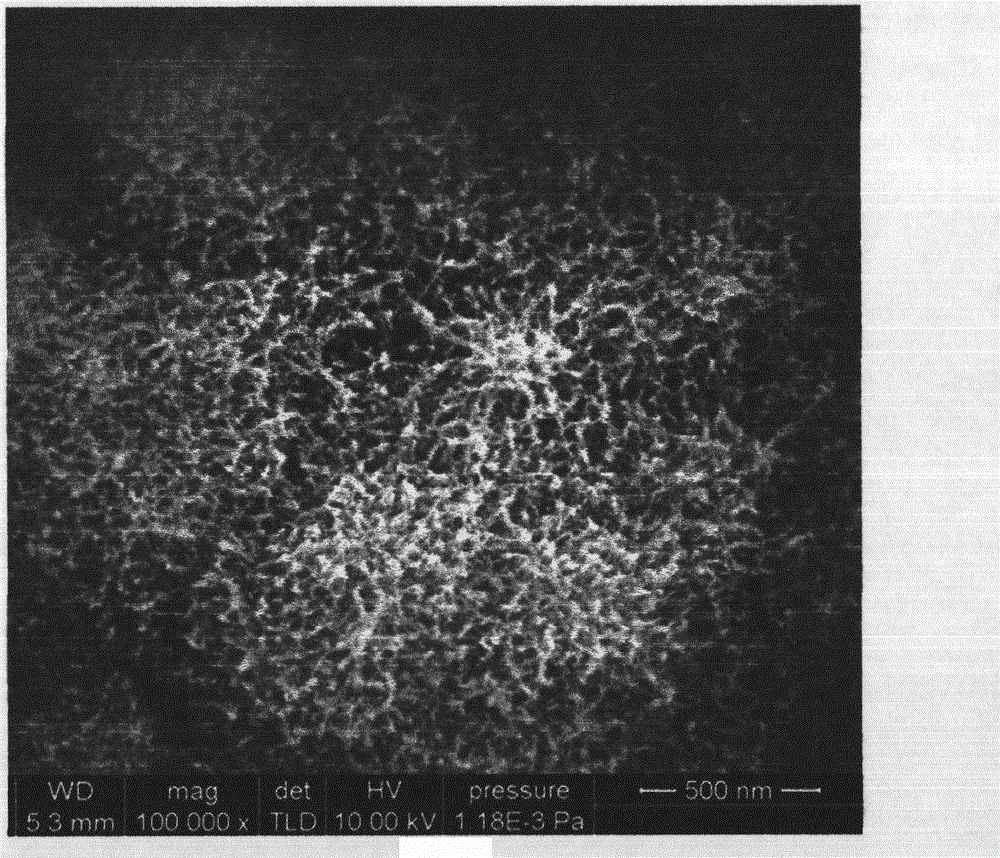

[0048] A method for directly growing nickel-cobalt oxide (NiO-CoO) composite nanowires on a metal titanium substrate, comprising the following steps:

[0049] a. Treatment of titanium substrate: ultrasonically clean the titanium sheet in dilute hydrochloric acid, absolute ethanol and deionized water for 5-10 minutes respectively, use the cleaned and dried titanium sheet as the anode, and place the platinum sheet as the cathode in 0.05-0.5mol / L of HF solution, react at room temperature for 1.0h at a voltage of 10-30V, and prepare TiO on the surface of the titanium substrate. 2 NT array, and then the resulting TiO 2 The NT array was calcined in a nitrogen atmosphere for 3h at a temperature of 400-500°C to improve the TiO 2 Conductivity of NT;

[0050] b. Soak the titanium substrate obtained in a. in a citric acid solution of Ph=1.5 for 12 to 24 hours;

[0051] c. Ni, Co salt solution: dissolve a certain amount of nickel nitrate hexahydrate and cobalt nitrate hexahydrate in d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com