Waterborne epoxy/acrylic resin emulsion with core-shell structure as well as preparation method and application thereof

An acrylic resin, water-based epoxy technology, applied in coatings, anti-corrosion coatings, etc., can solve the problems of poor film flexibility, impact resistance and corrosion resistance, prone to brittle fracture, low molecular weight, etc., to improve adhesion. ability, improved water dispersibility, high gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

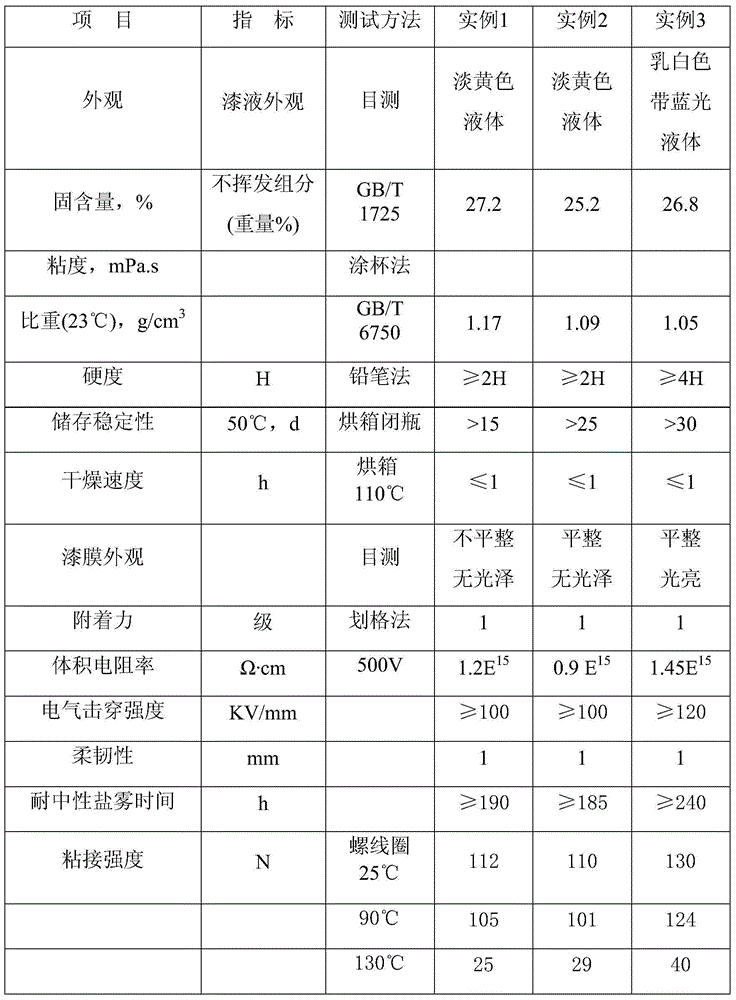

Examples

Embodiment 1

[0027] (1) Preparation of modified epoxy resin: put 136.2g of E-20 epoxy resin, 22.2g of phthalic anhydride and 0.41g of dimethylethylenediamine into reactor A, stir and slowly heat up To 130°C, detect the acid value during the reaction, when the acid value is <8mg KOH / g, it is the end of the reaction. Then, add 33g of capric acid and lower the temperature to 120°C to start esterification, keep the temperature of esterification reaction at 115-120°C, condense and reflux, and stop the reaction after reacting for 1.5-4 hours.

[0028](2) Preparation of the epoxy / acrylic amino resin emulsion of core-shell structure: add the α-methylstyrene monomer of 12.5g and the benzoyl peroxide (BPO) of 4.1g in the reactor B, use 40g propylene glycol Dissolve the methyl ether, raise the temperature to 70°C, wait until the BPO is completely dissolved, then mix 45g of acrylic acid, 35g of methacrylic acid and 0.2g of hydroquinone evenly, and slowly add them into the reactor B by dropping. After...

Embodiment 2

[0031] (1) Preparation of modified epoxy resin: the E-12 epoxy resin of 100g, the E-44 epoxy resin of 31g, the tetrahydrophthalic anhydride of 47g and the tris (2-hydroxyethyl) amine drop into reaction of 0.3g Reactor A is subjected to ring-opening reaction, stirred and slowly heated up to a reaction temperature of 130°C, and the end point of the reaction is when the acid value is less than 8 mg KOH / g. Then, add 28g of ricinoleic acid to carry out esterification reaction, react for 3 hours, and keep the temperature at 105°C.

[0032] (2) Preparation of epoxy / acrylic acid amino resin emulsion of core-shell structure: add 15g of styrene and 0.9g of benzoyl peroxide (BPO) in reactor B, dissolve with 20g propylene glycol methyl ether, be warming up to 70 ℃, after the BPO is completely dissolved, then mix 60g of acrylic acid, 30g of methyl methacrylate, 0.15g of p-benzoquinone and 20g of propylene glycol methyl ether, and slowly add it to the reactor B by dropping. After the dropw...

Embodiment 3

[0035] (1) Preparation of modified epoxy resin: the E-20 epoxy resin of 100g, the E-44 epoxy resin of 31g, the maleic anhydride of 47g and the ethylenediamine amine of 0.3g drop into reactor A to carry out For the ring-opening reaction, stir and slowly heat up to a reaction temperature of 130°C. When the acid value is less than 8mg KOH / g, it is the end of the reaction. Then, add 28g of oleic acid to carry out esterification reaction, react for 3 hours, and keep the temperature at 105°C.

[0036] (2) Preparation of epoxy / acrylic acid amino resin emulsion of core-shell structure: add 15g of styrene and 0.9g of benzoyl peroxide (BPO) in reactor B, dissolve with 20g propylene glycol methyl ether, be warming up to 70 ℃, after the BPO is completely dissolved, then mix 60g of acrylic acid, 30g of methyl methacrylate, 0.15g of p-benzoquinone and 20g of propylene glycol methyl ether, and slowly add it to the reactor B by dropping. After the dropwise addition, the temperature was raise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com