High-strength environment-friendly paper and preparation method and application thereof

A green, environmentally friendly, high-strength technology, applied in paper, papermaking, packaging paper, etc., can solve problems such as affecting the biocompatibility of bamboo fibers, and achieve the effect of improving bonding performance and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

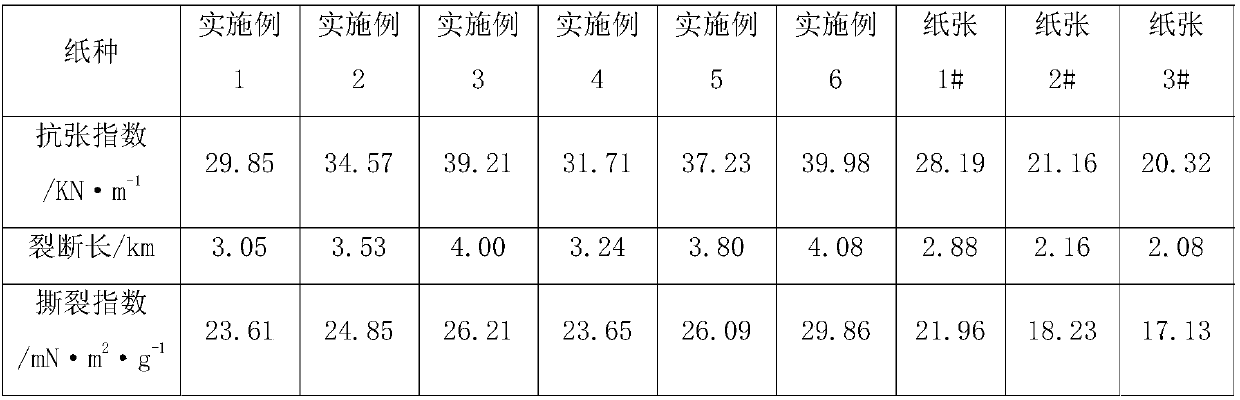

Examples

Embodiment 1

[0027] A preparation method for high-strength green environmental protection paper, comprising the following steps:

[0028] (1) the bamboo pulp raw material that 300g pulp is thick is 10% is placed in the beating of PFI mill, obtains the bamboo pulp that beating degree is 30 ° of SR;

[0029] (2) take by weighing the bamboo pulp that obtains in a certain amount of step (1) and add concentration and be in the cationic guar gum solution of 0.5wt%, the absolute dry mass of bamboo pulp is the 6wt% of cationic guar gum solution quality, at 25 ℃ Under conditions, after insulation 20min, take out bamboo pulp, wash 3 times with the distilled water of 3000ml, obtain the bamboo pulp after the pretreatment used in the experiment;

[0030] (3) the bamboo pulp after the pretreatment in step (2) and the PLA fiber that the cationic guar gum solution is not processed are on the paper machine according to 80g / m with the absolute dry mass ratio of 7:3 2 Quantitative papermaking can be done to...

Embodiment 2

[0032] A preparation method for high-strength green environmental protection paper, comprising the following steps:

[0033] (1) the bamboo pulp raw material that 300g pulp concentration is 10% is placed in the beating of PFI mill, obtains the bamboo pulp that beating degree is 40 ° of SR;

[0034] (2) take by weighing the bamboo pulp that obtains in a certain amount of step (1) and add concentration and be in the cationic guar gum solution of 1wt%, the absolute dry mass of bamboo pulp is the 8wt% of cationic guar gum solution quality, at 30 DEG C of conditions Next, after being kept warm for 25min, take out the bamboo pulp, wash 3 times with the distilled water of 3000ml, obtain the bamboo pulp after the pretreatment used in the experiment;

[0035] (3) the bamboo pulp after the pretreatment in step (2) and the PLA fiber that the cationic guar gum solution is not processed are on the paper machine according to 100g / m with the absolute dry mass ratio of 7:3 2 Quantitative pap...

Embodiment 3

[0037] A preparation method for high-strength green environmental protection paper, comprising the following steps:

[0038] (1) the bamboo pulp raw material that 300g pulp is thick is 10% is placed in the beating of PFI mill, obtains the bamboo pulp that beating degree is 50 ° of SR;

[0039] (2) take by weighing the bamboo pulp that obtains in a certain amount of step (1) and add concentration and be in the cationic guar gum solution of 1.5wt%, the absolute dry mass of bamboo pulp is the 10wt% of cationic guar gum solution quality, at 35 ℃ Under the condition, after being incubated for 30min, take out the bamboo pulp, wash 3 times with the distilled water of 3000ml, obtain the bamboo pulp after the pretreatment used in the experiment;

[0040] (3) with the bamboo pulp after the pretreatment in step (2) and the PLA fiber that the cationic guar gum solution is not processed with the absolute dry mass ratio of 7:3, on paper machine according to 120g / m 2 Quantitative papermakin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com