Antibacterial aluminum alloy and preparation method thereof

A technology for aluminum alloy and aluminum alloy surface, applied in metal material coating process, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of peeling, poor adhesion of surface coating, increasing process difficulty and production cost, etc. To achieve the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

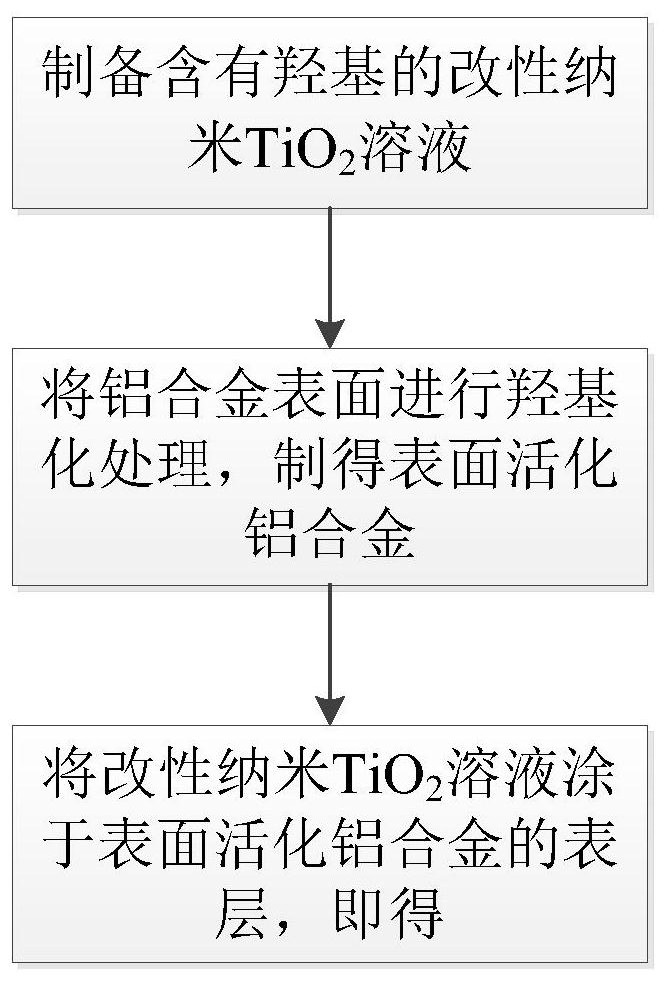

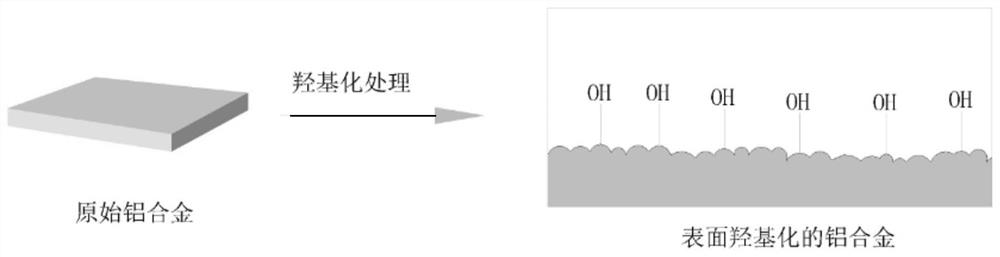

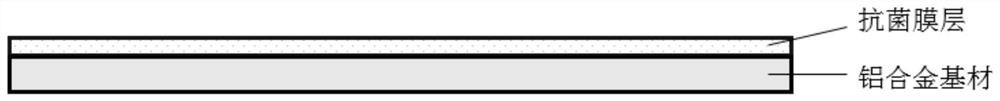

[0037] The application provides a method for preparing an antibacterial aluminum alloy, wherein the surface of the aluminum alloy is treated with hydroxylation, so that the number of hydroxyl groups on the surface is greatly improved, and the nano-TiO 2 deposition sites on its surface. Further, the antibacterial liquid is modified nano-TiO 2 solution, modified nano-TiO 2 Contains a large number of hydroxyl groups, when modified nano-TiO 2 When the solution is applied to the aluminum alloy surface, the modified nano-TiO 2 The contained hydroxyl groups chemically react with the abundant hydroxyl groups on the surface of the aluminum alloy, thereby transforming the nano-TiO 2 Chemically grafted onto the surface of the aluminum alloy substrate, the antibacterial particles can be more firmly combined with the substrate. Such as figure 1 Shown, the preparation method that the application provides comprises:

[0038] Preparation of modified nano-TiO containing hydroxyl groups ...

Embodiment 1

[0063] This implementation prepares an antibacterial aluminum alloy, and the specific steps are as follows:

[0064] 1. Preparation of modified nano-TiO 2 Solution:

[0065] 1) Mix 10 parts of butyl titanate, 7 parts of diethanolamine, and 200 parts of ethanol, and stir with a stirrer for 40 minutes at a stirring speed of 450 rpm to obtain a yellow clear solution A;

[0066] 2) 90 parts of water and 110 parts of ethanol were mixed and stirred at a stirring speed of 450 rpm, and stirred for 15 minutes to obtain solution B;

[0067] 3) Slowly add solution B to the stirred solution A, keep the solution temperature at 50°C, and continue to stir for 45 minutes to obtain nano-TiO 2 solution;

[0068] 4) Take 4 parts of sodium silicate and add to nano TiO 2 solution and stirred for 45 minutes; then added 400 parts of silane and stirred evenly to keep the pH at 8-9, and continued to stir for 25 minutes to obtain the product.

[0069] 2. Preparation of surface activated aluminum a...

Embodiment 2

[0079] This implementation prepares an antibacterial aluminum alloy, and the specific steps are as follows:

[0080] 1. Preparation of modified nano-TiO 2 Solution:

[0081] 1) Mix 25 parts of butyl titanate, 10 parts of diethanolamine, and 150 parts of ethanol, and stir with a stirrer for 50 minutes at a stirring speed of 450 rpm to obtain a yellow clear solution A;

[0082] 2) 100 parts of water and 120 parts of ethanol were mixed and stirred at a stirring speed of 450 rpm, and stirred for 20 minutes to obtain solution B;

[0083] 3) Slowly add solution B to the stirred solution A, keep the solution temperature at 60°C, and continue to stir for 45 minutes to obtain nano-TiO 2 solution;

[0084] 4) Take 5 parts of sodium silicate and add it to nano TiO 2 solution and stirred for 45 minutes; then added 500 parts of silane and stirred evenly to keep the pH at 8-9, and continued to stir for 30 minutes to obtain the product.

[0085] 2. Preparation of surface activated aluminu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com