Preparation method of high-strength high-barrier TPU composite material

A composite material and high-barrier technology, applied in the field of polymer composite material synthesis, to achieve the effect of increasing the number of hydroxyl groups, increasing the degree of cross-linking, and increasing the number of reaction sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

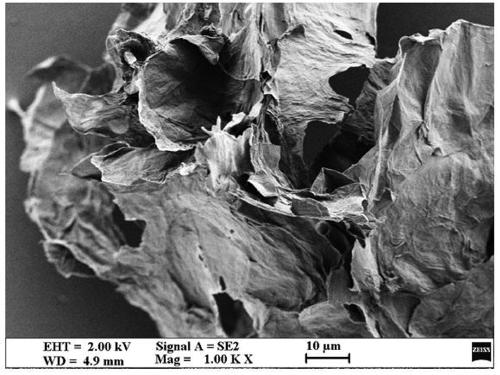

[0037]1) Preparation of graphene oxide: Take 1g of flake graphite, add it to 23mL of concentrated sulfuric acid and mix well, keep magnetic stirring; slowly add 3g of KMnO in batches under the condition of temperature 4 , 0.5g of NaNO 3 , the reaction continued for 4 hours, raised to 35°C and reacted for 2 hours, then raised the temperature to 98°C; added 44mL deionized water to the system, and added 5wt% H2 dropwise after 10min 2 o 2 Until the solution is golden yellow and no bubbles are generated, finally add 20mL of 5wt% HCl; centrifuge and wash the suspension several times until pH = 7, and freeze-dry at -80°C after ultrasonication for 2 hours to obtain graphene oxide;

[0038] 2) Preparation of modified graphene oxide: Add 0.0335g of graphene oxide prepared in step 1) into 10mL of DMF to obtain graphene oxide / DMF suspension, ultrasonically disperse for 1h, add 0.1675g of chitosan under magnetic stirring at 500rpm, React at 25°C for 12 hours to obtain a modified graphene ...

Embodiment 2

[0045] 1) Preparation of graphene oxide: Take 1g of flake graphite, add it to 23mL of concentrated sulfuric acid and mix well, keep magnetic stirring; slowly add a total of 3g of KMnO in batches at low temperature (4 , 0.5g NaNO 3 , the reaction continued for 4 hours, raised to medium temperature (35°C) and then reacted for 2 hours, then raised the temperature to 98°C; added 44mL deionized water to the system, and added 5wt%H2 dropwise after 10min 2 o 2 Until the solution is golden yellow and no bubbles are generated, finally add 20mL of 5wt% HCl; centrifuge and wash the suspension several times until pH = 7, and freeze-dry at -80°C after ultrasonication for 2 hours to obtain graphene oxide;

[0046] 2) Modification of graphene oxide: add 0.0670g graphene oxide prepared in step 1) to 10mL DMF to obtain graphene oxide / DMF suspension, ultrasonically disperse for 1h, add 0.3350g chitosan under the condition of 500rpm magnetic stirring, 25 °C for 12 hours to obtain a modified gra...

Embodiment 3

[0053] 1) Preparation of graphene oxide: Take 1g flake graphite, add it to 23mL concentrated sulfuric acid and mix well, keep magnetic stirring; slowly add 3gKMnO in batches at low temperature (4 , 0.5gNaNO 3 , the reaction continued for 4 hours, raised to medium temperature (35°C) and reacted for 2 hours, then raised the temperature to 98°C; added 44mL deionized water to the system, and added 5% H2O dropwise after 10min 2 o 2 Until the solution is golden yellow and no bubbles are generated, finally add 20mL of 5% HCl; centrifuge and wash the suspension several times until PH = 7, and freeze-dry at -80°C after ultrasonication for 2 hours to obtain graphene oxide;

[0054] 2) Modification of graphene oxide: Add 0.1005g of graphene oxide prepared in step 1) to 10mL of DMF to obtain a graphene oxide / DMF suspension, ultrasonically disperse for 1h, and add 0.5025g of chitosan under the condition of 500rpm magnetic stirring, React at 25°C for 12 hours to obtain a modified graphene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com