Modified hindered phenol damping agent, and preparation method and applications thereof

A technology of hindered phenol and damping agent is applied in the field of damping materials, which can solve the problems of easy migration and long-term retention of damping effect, and achieve the effect of overcoming easy migration, enhancing compatibility and improving damping performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

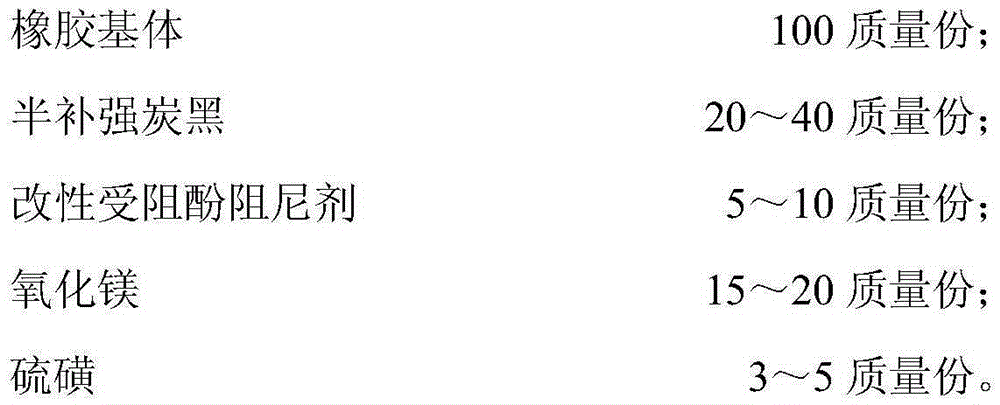

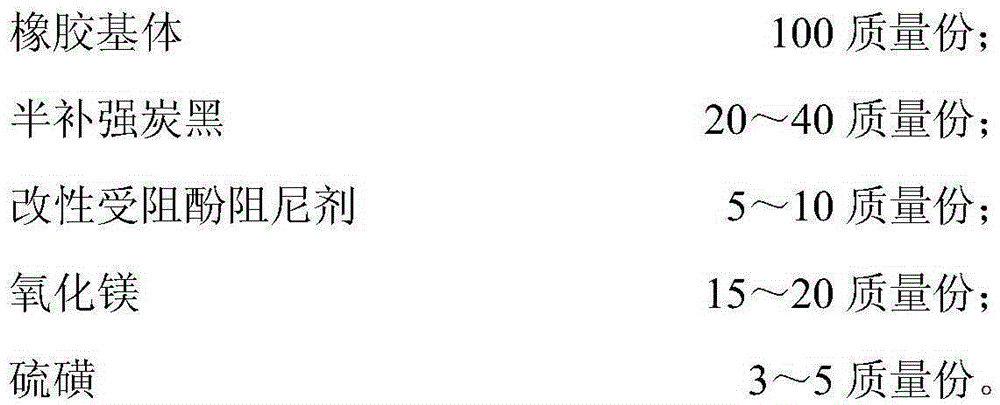

Method used

Image

Examples

Embodiment 1

[0034] 1. Preparation of N,N-dihydroxyethyl-3-aminopropionic acid methyl ester monomer:

[0035] Add 0.2mol methyl acrylate, 0.4mol diethanolamine and 20mL methanol into the three-necked flask, 2 Stir and react at 20°C for 50 minutes under protection, then raise the temperature to 30°C and keep it warm for 6 hours, then end the reaction, vacuumize to remove excess methanol solvent, and obtain a colorless and transparent oily substance, which is: N,N-dihydroxyethyl- Methyl 3-aminopropionate monomer.

[0036] 2. Preparation of modified hindered phenol damping agent:

[0037] Take by weighing 50g of BASF Antioxidant 1010, 80g of the N,N-dihydroxyethyl-3-aminopropionic acid methyl ester monomer and 0.5g of p-toluenesulfonic acid prepared in the above steps in a four-necked flask, in N 2 Under protection, the reaction was stirred at 110°C for 7 hours, and then vacuumized to remove unreacted N,N-dihydroxyethyl-3-aminopropionic acid methyl ester monomer, and the resulting residue w...

Embodiment 2

[0039] 1. Preparation of N,N-dihydroxyethyl-3-aminopropionic acid methyl ester monomer:

[0040] Add 0.3mol methyl acrylate, 0.6mol diethanolamine and 25mL methanol into the three-necked flask, 2 Stir and react at 25°C for 45 minutes under protection, then raise the temperature to 40°C and keep the temperature for 5 hours, then end the reaction, vacuumize to remove excess methanol solvent, and obtain a colorless and transparent oil, which is: N,N-dihydroxyethyl- Methyl 3-aminopropionate monomer.

[0041] 2. Preparation of modified hindered phenol damping agent:

[0042] Take by weighing 65g of BASF Antioxidant 1076, 90g of the N,N-dihydroxyethyl-3-aminopropionic acid methyl ester monomer and 0.6g of p-toluenesulfonic acid prepared in the above steps in a four-necked flask, in N 2 Under protection, the reaction was stirred at 100°C for 8 hours, and then vacuumized to remove unreacted N,N-dihydroxyethyl-3-aminopropionic acid methyl ester monomer, and the resulting residue was ...

Embodiment 3

[0044] 1. Preparation of N,N-dihydroxyethyl-3-aminopropionic acid methyl ester monomer:

[0045] Add 0.4mol methyl acrylate, 0.8mol diethanolamine and 30mL methanol into the three-necked flask, 2 Stir and react at 30°C for 40min under protection, then raise the temperature to 50°C and keep it warm for 4h, then end the reaction, vacuumize to remove excess methanol solvent, and obtain a colorless and transparent oily substance, which is: N,N-dihydroxyethyl- Methyl 3-aminopropionate monomer.

[0046] 2. Preparation of modified hindered phenol damping agent:

[0047] Take by weighing 80g of BASF Antioxidant 1076, 100g of the N,N-dihydroxyethyl-3-aminopropionic acid methyl ester monomer and 0.8g of p-toluenesulfonic acid prepared in the above steps in a four-necked flask, in N 2 Under protection, the reaction was stirred at 110°C for 7 hours, and then vacuumized to remove unreacted N,N-dihydroxyethyl-3-aminopropionic acid methyl ester monomer, and the resulting residue was washed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Branching factor | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com