Preparation method for microbial carrier

A technology of microbial carrier and preparation steps, applied in the direction of immobilized on or in the inorganic carrier, chemical instruments and methods, phosphorus compounds, etc., can solve the problems of low microbial load, low mechanical strength, poor biocompatibility, etc., and achieve The effect of increasing the attachment space, increasing the load capacity, and improving the survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

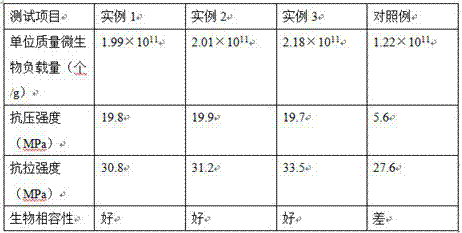

Examples

example 1

[0025] Weigh the oyster shells and put them in water, heat and boil for 1 hour, take out the boiled oyster shells and put them into a jet mill to grind for 30 minutes to obtain oyster shell powder, then mix the oyster shell powder with a concentration of 0.1mol / L according to the mass ratio of 1:5 After mixing the hydrochloric acid, stir and react for 1 hour, then centrifuge with a centrifuge at 2000r / min for 10 minutes to separate the supernatant; weigh the cotton stalks and cut them into small pieces with a length of 1 cm to obtain cotton stalks, and mix the cotton stalks and biogas slurry by The mass ratio is 1:3, mixed and placed under the condition of temperature of 35°C, and left to be slightly rotted for 3 days. Mix the powder and absolute ethanol at a mass ratio of 1:10, heat up to 40°C, stir and react for 1 hour to obtain a mixed suspension, then add phosphorus pentoxide and the mixed suspension to the ultrasonic dispersion at a mass ratio of 1:15 In the instrument, u...

example 2

[0027] Weigh the oyster shells and put them in water to heat and boil for 2 hours, take out the boiled oyster shells and put them into a jet mill to grind for 35 minutes to obtain oyster shell powder. After mixing the hydrochloric acid, stir and react for 2 hours, and centrifuge at 2500r / min for 13 minutes to separate the supernatant; weigh the cotton stalks and cut them into small pieces with a length of 1 cm to obtain cotton stalks. The mass ratio is 1:3, mixed and placed under the condition of temperature of 40°C, and left to be slightly rotted for 4 days. Mix the powder and absolute ethanol at a mass ratio of 1:10, heat up to 45°C, stir and react for 2 hours to obtain a mixed suspension, and then add phosphorus pentoxide and the mixed suspension to the ultrasonic dispersion at a mass ratio of 1:15 In the instrument, ultrasonic dispersion treatment was performed for 35 minutes at a frequency of 35 kHz to obtain a dispersion liquid, and then the pH of the dispersion liquid w...

example 3

[0029] Weigh the oyster shells, put them in water, heat and boil for 2 hours, take out the boiled oyster shells, put them into a jet mill and pulverize them for 40 minutes to obtain oyster shell powder, and then mix the oyster shell powder with a concentration of 0.1mol / L according to the mass ratio of 1:5 After mixing the hydrochloric acid, stir and react for 2 hours, and centrifuge at 3000r / min for 15 minutes to separate the supernatant; weigh the cotton stalks and cut them into small pieces with a length of 2cm to obtain cotton stalks. The mass ratio is 1:3, mixed and placed under the condition of temperature of 45°C, and left to be slightly rotted for 5 days. Mix the powder and absolute ethanol at a mass ratio of 1:10, heat up to 50°C, stir and react for 2 hours to obtain a mixed suspension, and then add phosphorus pentoxide and the mixed suspension to the ultrasonic dispersion at a mass ratio of 1:15 In the instrument, under the condition of frequency of 40kHz, the ultras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com