Patents

Literature

32results about How to "Multiple attachment sites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sulfate reducing bacteria embedded particle for treating ionic rare earth mine wastewater as well as preparation method and application thereof

ActiveCN111517477AReduce inhibitionRaise the pHWater treatment compoundsClimate change adaptationSulfate radicalsEnvironmental engineering

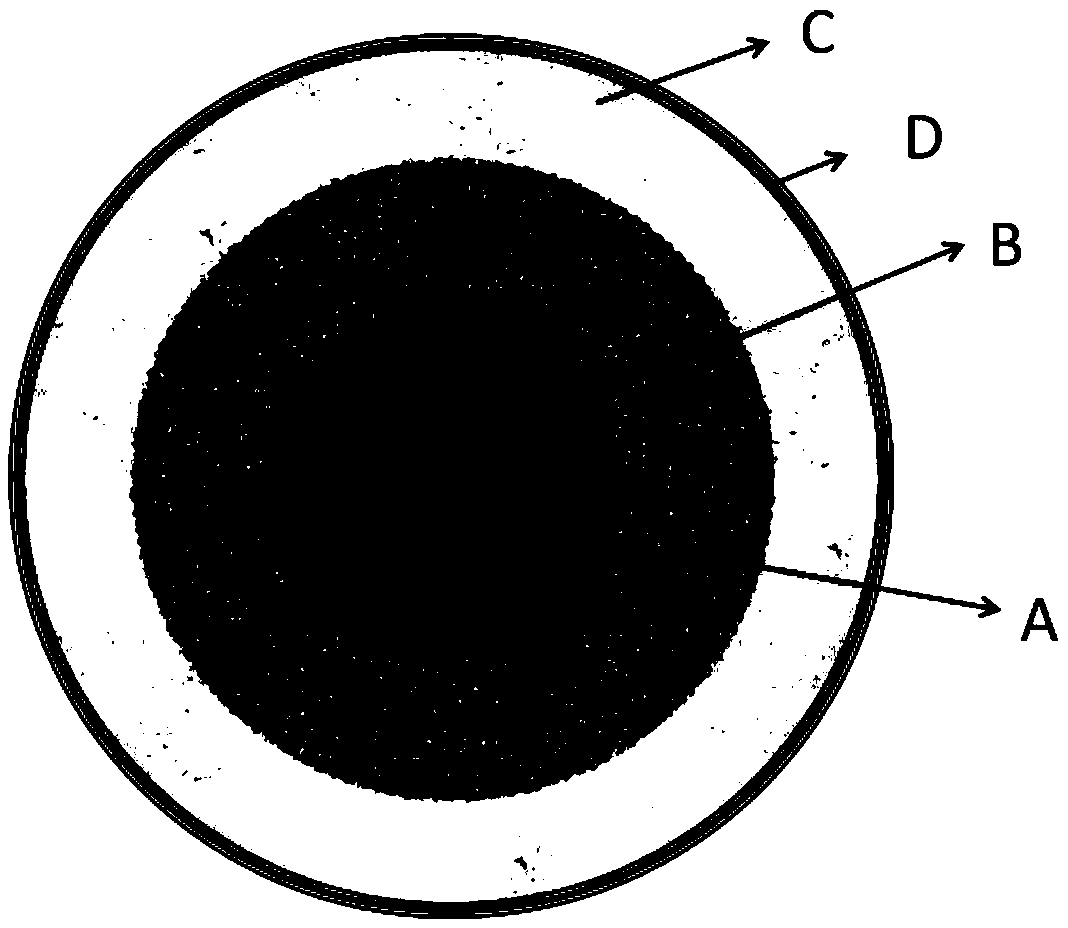

The invention relates to the field of water environment protection, in particular to sulfate reducing bacteria embedded particles for treating ionic rare earth mine wastewater as well as a preparationmethod and an application of the sulfate reducing bacteria embedded particles, and solves the problem that sulfate reducing bacteria in SRB treatment acid mine wastewater are poisoned by heavy metalsand insufficient carbon sources to influence the practical application effect. The embedded particle is of a multi-layer structure and is sequentially composed of a sulfate reducing bacteria biofilmculturing charcoal layer, a composite hydrolase slow-release carbon source layer, an adsorption layer and a cross-linking layer from inside to outside. The invention provides an embedded particle integrated double hydrolysis catalysis system, the release of a slow-release carbon source can be accelerated, an anaerobic environment required by reaction is provided, the toxic action of heavy metals and acid radical ions on sulfate reducing bacteria is reduced, the practical application effect is improved, and sulfate radicals and heavy metal ions in acidic mine wastewater and ionic rare earth mine wastewater can be effectively reduced.

Owner:JIANGXI ACADEMY OF SCI

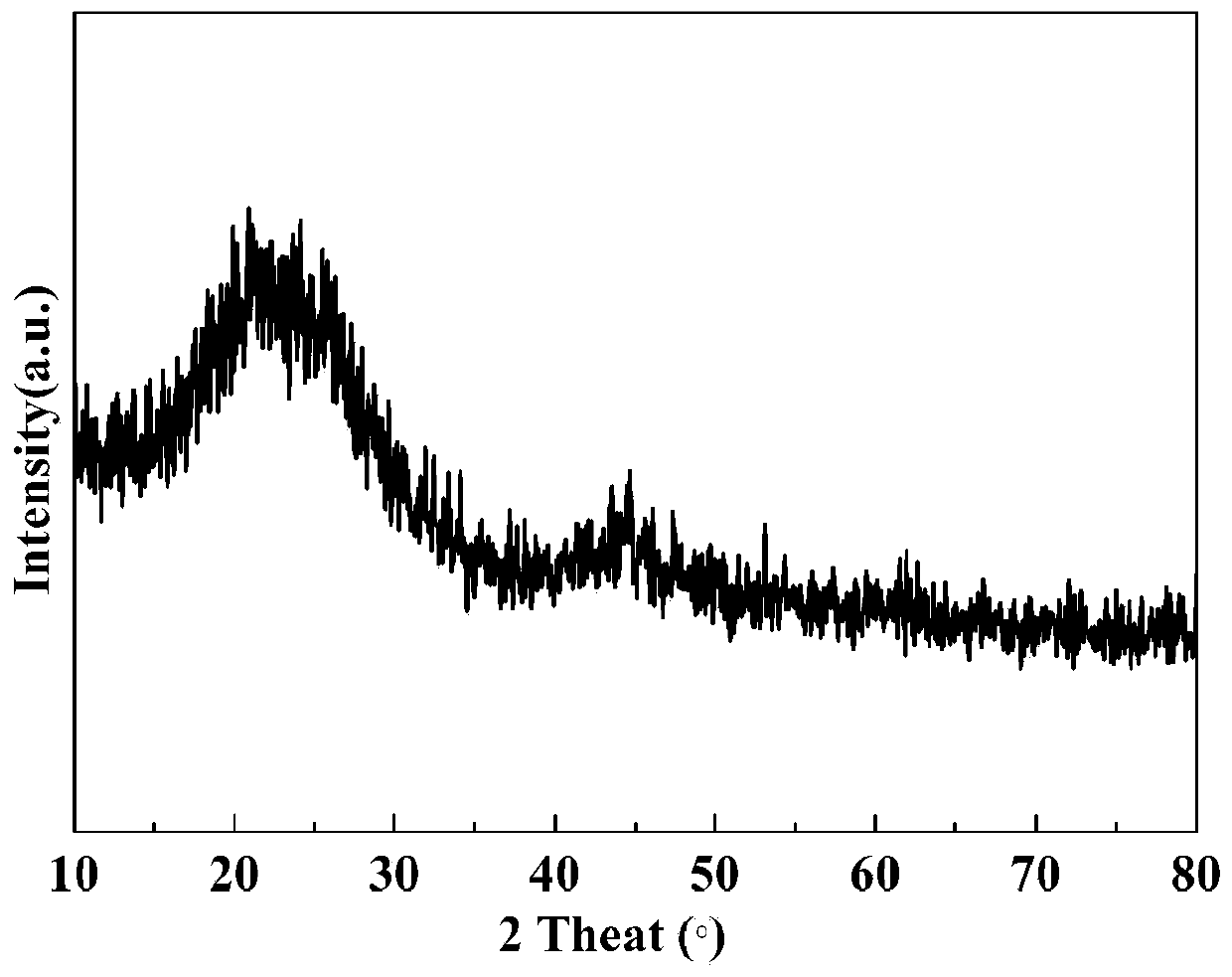

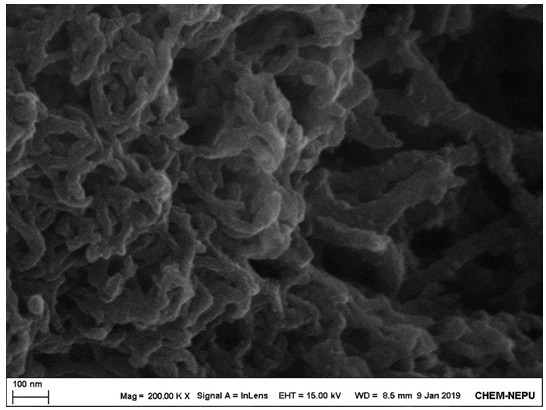

Preparation method and application of graphene oxide

ActiveCN109704322AEnhanced bioaugmentationAvoid churnCarbon compoundsTreatment with anaerobic digestion processesWater bathsIce water

The invention belongs to the technical field of sewage treatment, and relates to a preparation method and application of graphene oxide. The preparation method of graphene oxide comprises the steps:adding graphite powder to a beaker containing concentrated sulfuric acid for pre-oxidation firstly, then adding potassium permanganate to the beaker in an ice water bath, performing stirring, removingthe ice water bath, adding deionized water at room temperature, performing stirring, then adding a saturated hydrogen peroxide solution slowly until the color of the mixed liquid turns golden yellow,and performing stirring; and finally, performing washing and precipitation on the obtained mixed liquid, and performing centrifugation, dialysis and freeze drying so as to obtain the brown-yellow floc graphene oxide. The whole preparation process does not need complicated temperature control, and has easy operation and no high-temperature production stages, the production safety factor is improved, meanwhile, more energy saving is achieved, and the production cost is reduced; and the produced graphene oxide powder has good strengthening performance for anammox bacteria, and is suitable for industrial production, and good economic and environmental benefits can be achieved.

Owner:青岛绿洁坤环保科技有限公司

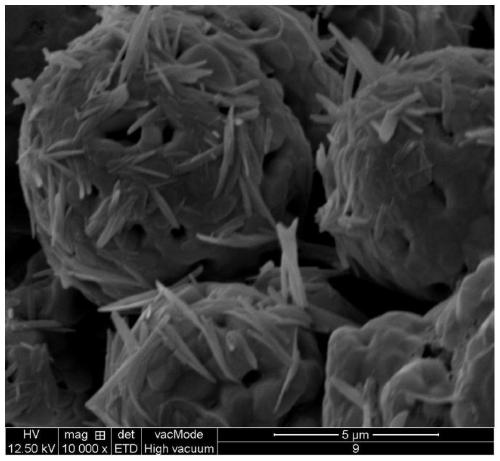

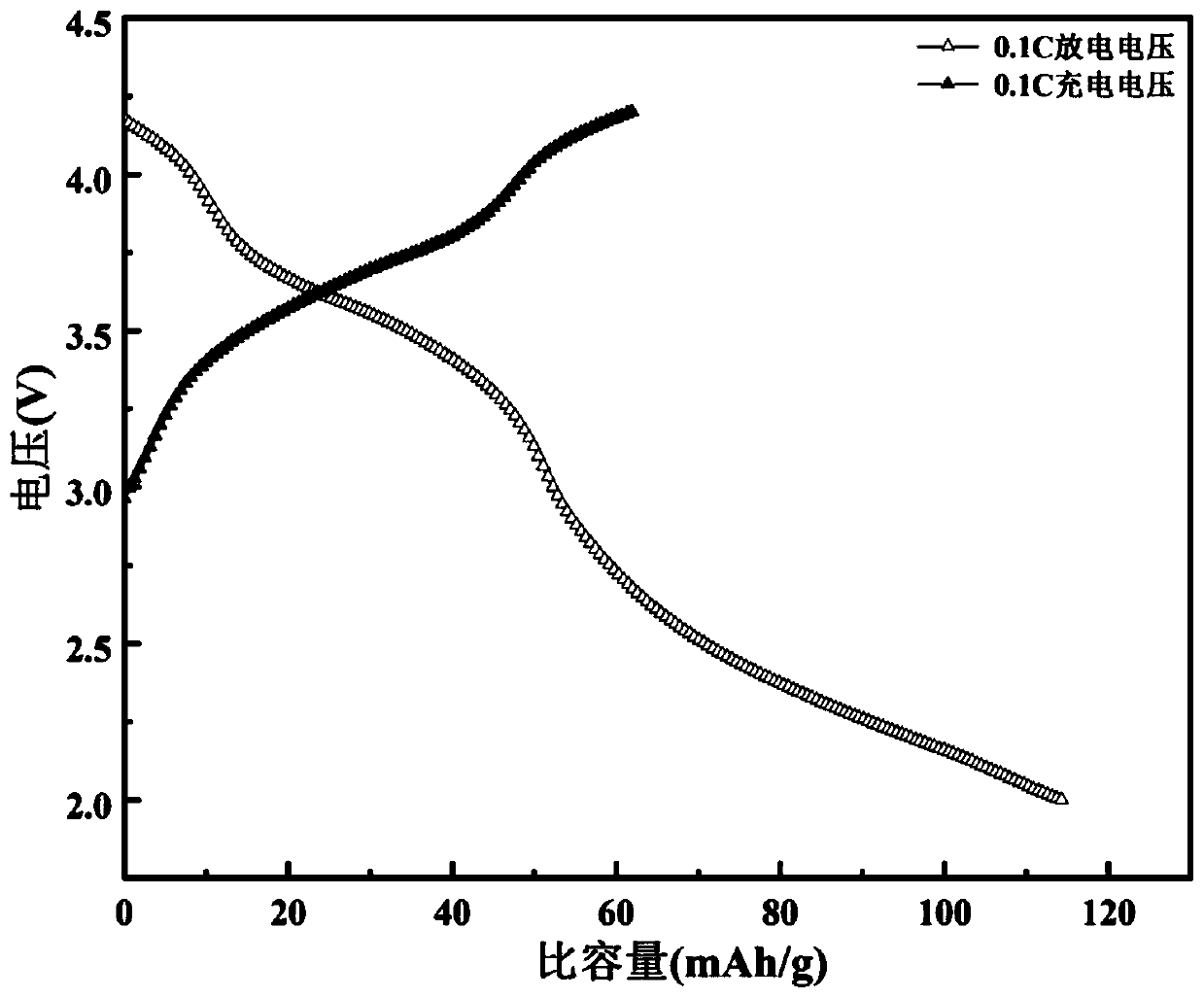

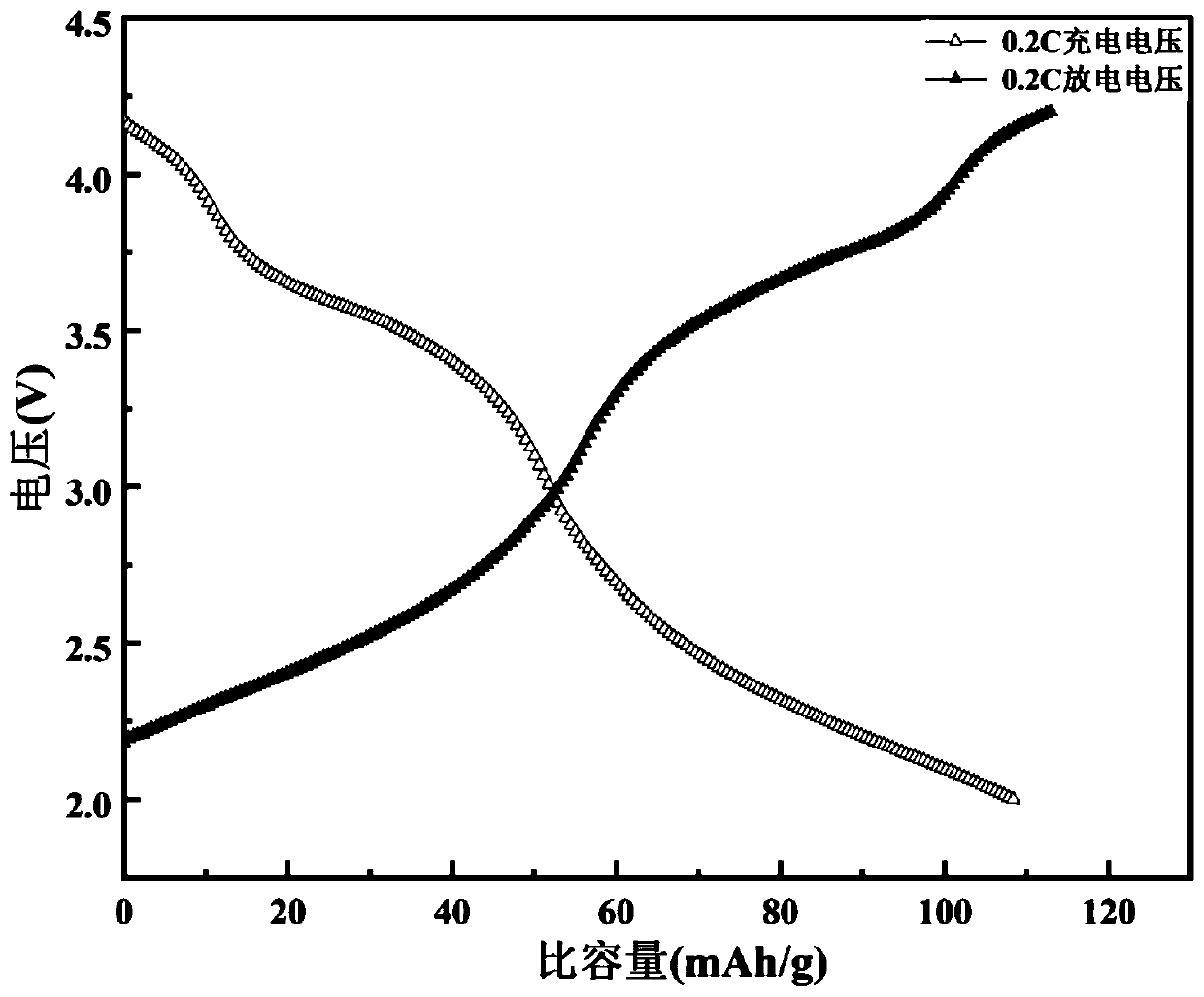

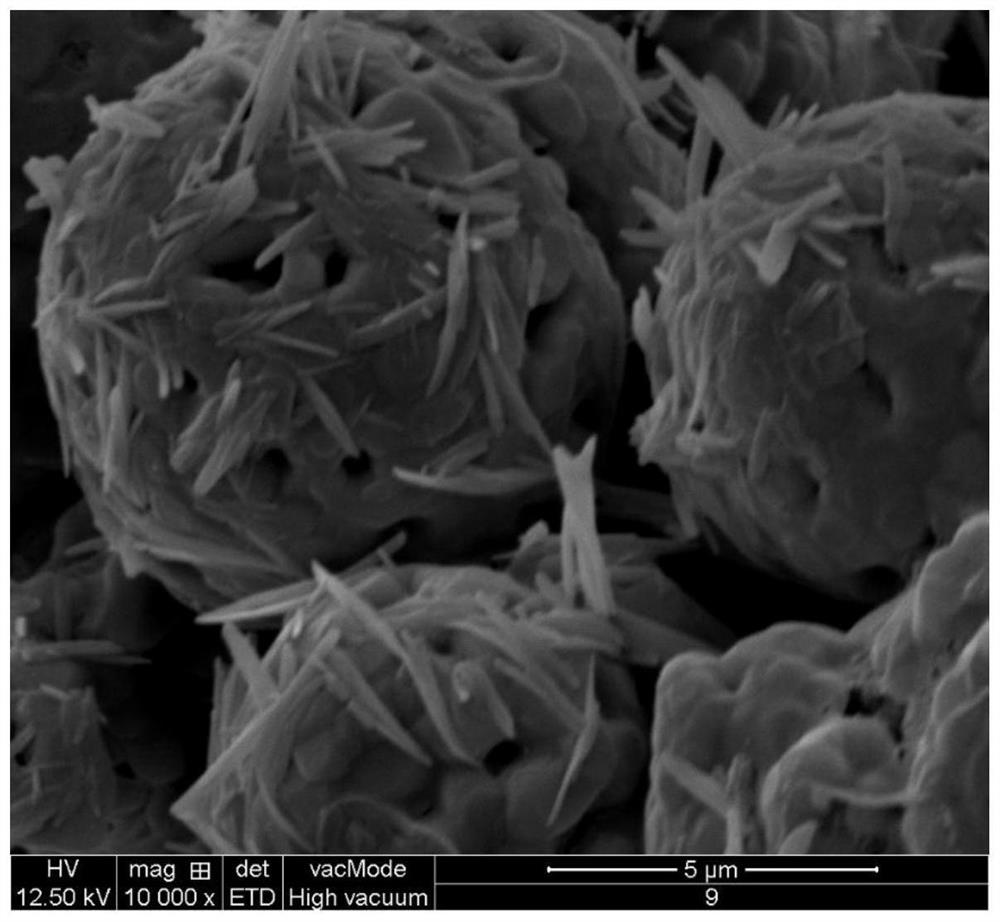

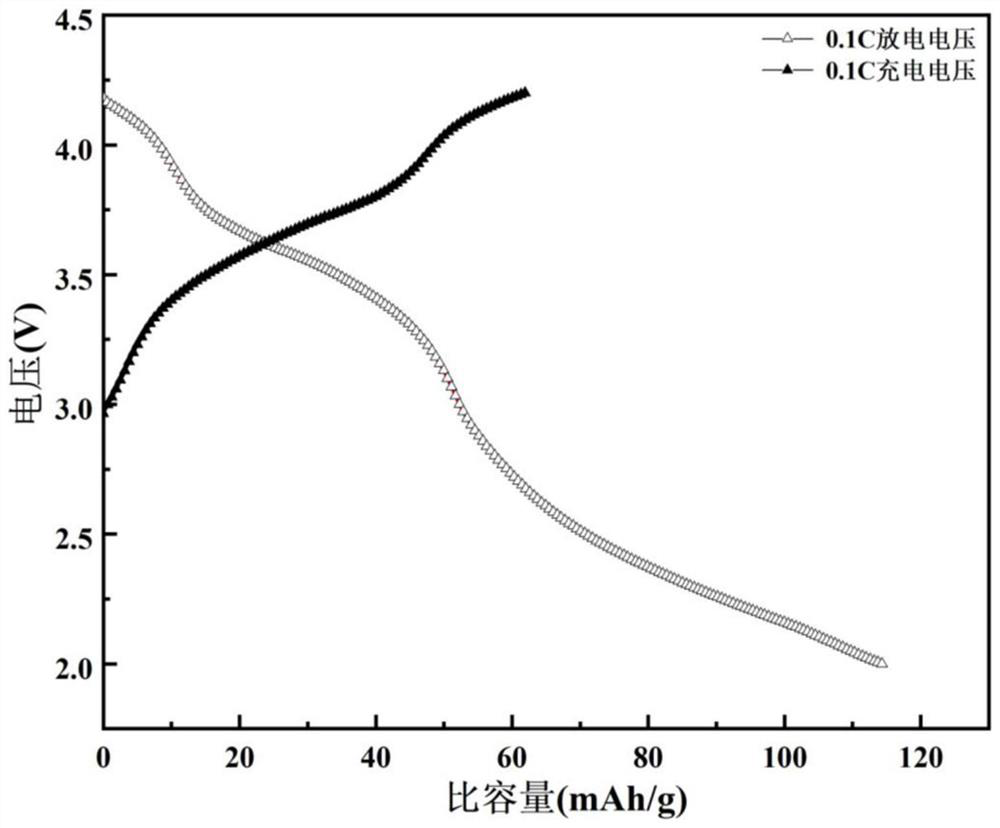

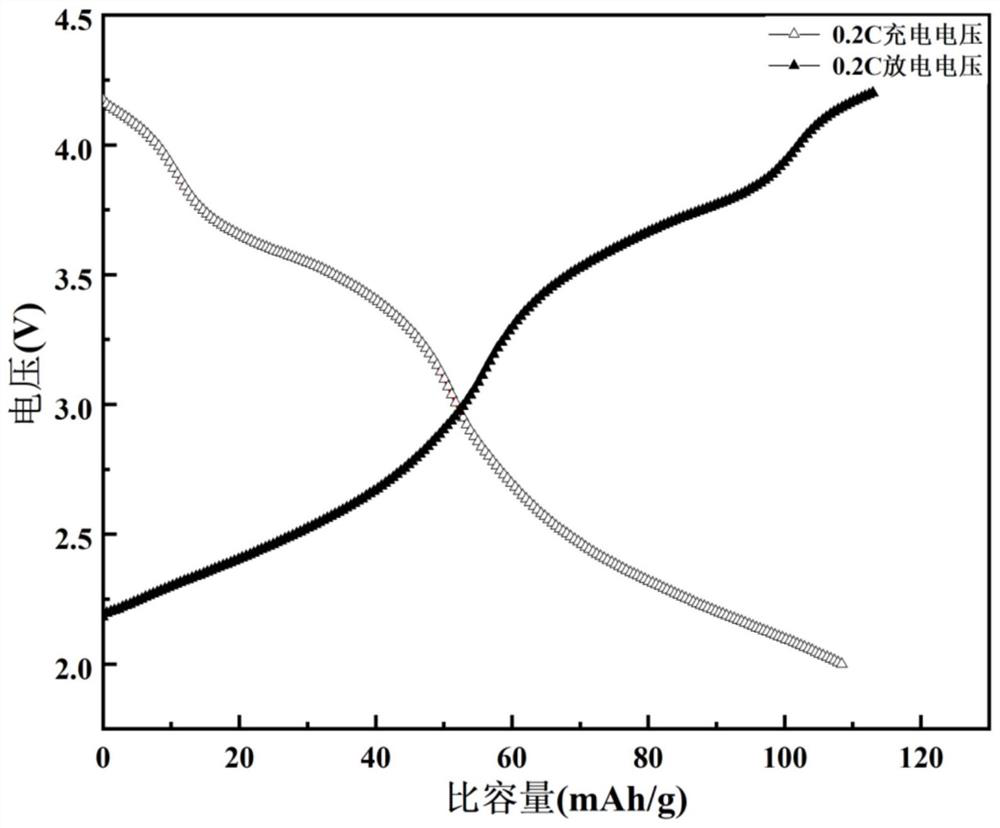

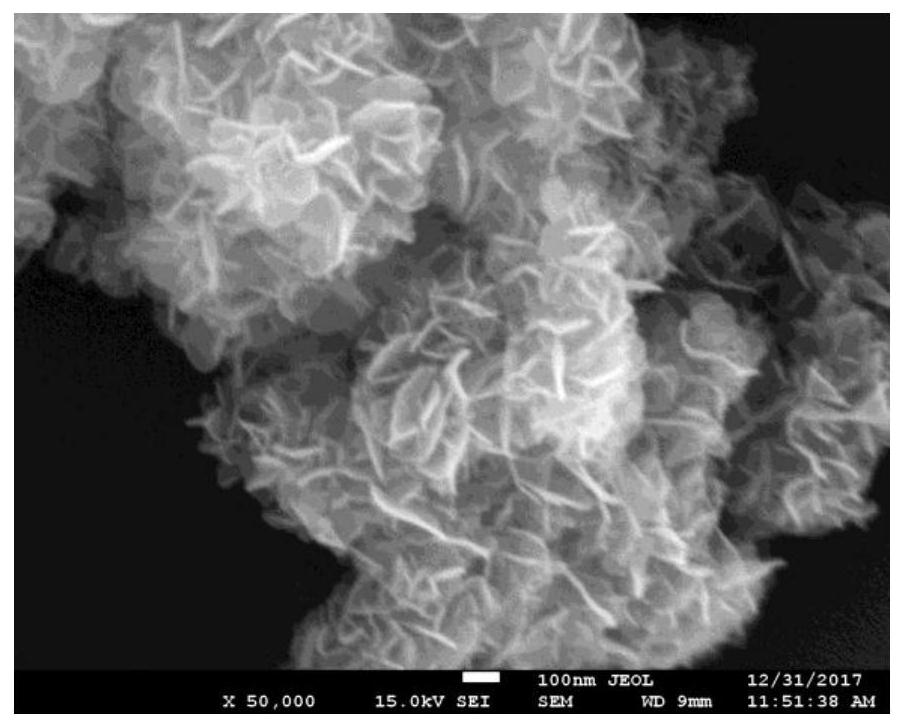

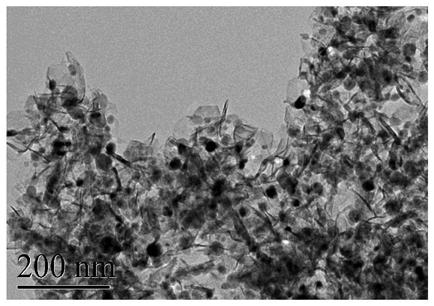

Micron hollow porous composite spherical sodium ion battery cathode material and preparation method thereof

ActiveCN111180689AImprove structural stabilityShorten the de-embedding pathSecondary cellsPositive electrodesElectrolytic agentElectrical battery

The invention discloses a micron hollow porous composite spherical sodium ion battery cathode material and a preparation method thereof. The cathode material is of a micron-sized hollow porous composite spherical structure, is formed by self-assembling a sheet-shaped structure and a needle-shaped structure, and has a chemical formula of NaxMn1-y-zNiyCozO2, wherein 0<x<=1, 0<=y<=1, 0<=z<=1, and 0<=y+z<=1. The invention also comprises a preparation method of the battery cathode material. The hollow sphere structure of the cathode material shortens the de-intercalation path of sodium ions; the needle-shaped structure provides more attachment sites for sodium ions and is beneficial to preventing agglomeration among particles; the porous structure is beneficial to the contact of the material with a conductive agent and an electrolyte, so that the conductivity of an electrode prepared from the material is improved; the battery positive electrode material is good in structural stability, anda battery assembled by an electrode prepared from the material is good in rate capability; the method is simple in process, required equipment is consistent with an existing industrialized lithium cobalt oxide and nickel-cobalt-manganese ternary cathode material process, and the lithium cobalt oxide and nickel-cobalt-manganese ternary cathode material can be directly produced by an existing production line.

Owner:CENT SOUTH UNIV

Oxygen supply type landscape special fertilizer for degrading chromium element in soil

InactiveCN107021817AWell mixedImprove survival rateCalcareous fertilisersAlkali orthophosphate fertiliserPhosphateRapeseed

The invention discloses oxygen supply type landscape special fertilizer for degrading a chromium element in soil. The oxygen supply type landscape special fertilizer are prepared from raw materials of dry marsh mud, peat, a rapeseed cake, a mushroom residue, manioc waste, pine sawdust, a modified oxygenating agent, a modified degrading agent, a modified slow release agent, monoammonium phosphate, potassium fulvate, ammonium chloride, ammonium dibasic phosphate, ferrous sulfate, zinc sulfate, ammonium molybdate, compound ammonium nitrate, ammonia sulfate, stannous chloride, sodium hydrogen sulfite, sodium borate, vermiculite, lime powder, kaolin powder and diatomite. The landscape special fertilizer provided by the invention can degrade the chromium element in the soil; the enrichment effect of the chromium element can be avoided; further, the sufficient oxygen can be provided for the growth of a landscape crop; the growth of the landscape crop is promoted.

Owner:天长市天兴园林绿化工程有限公司

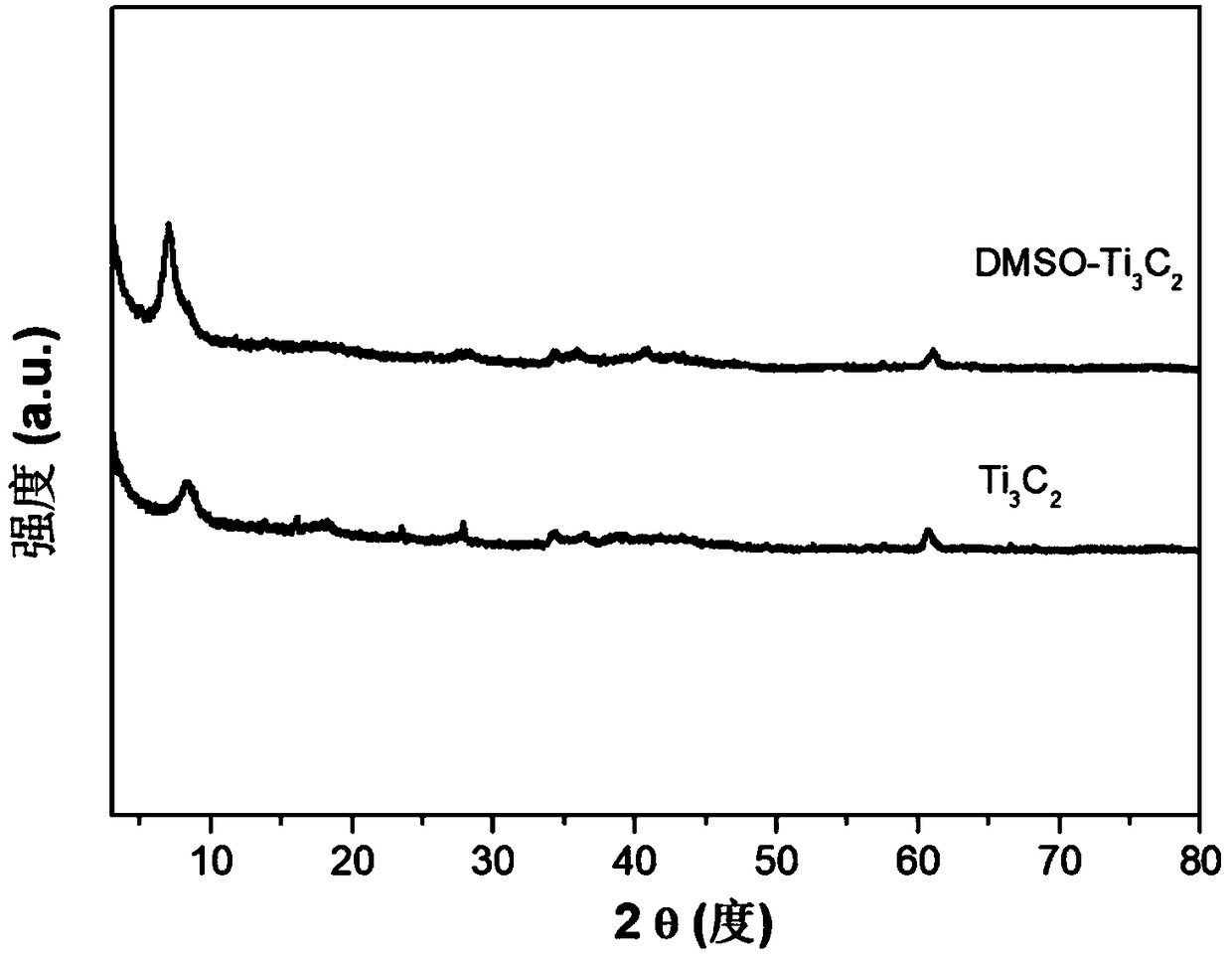

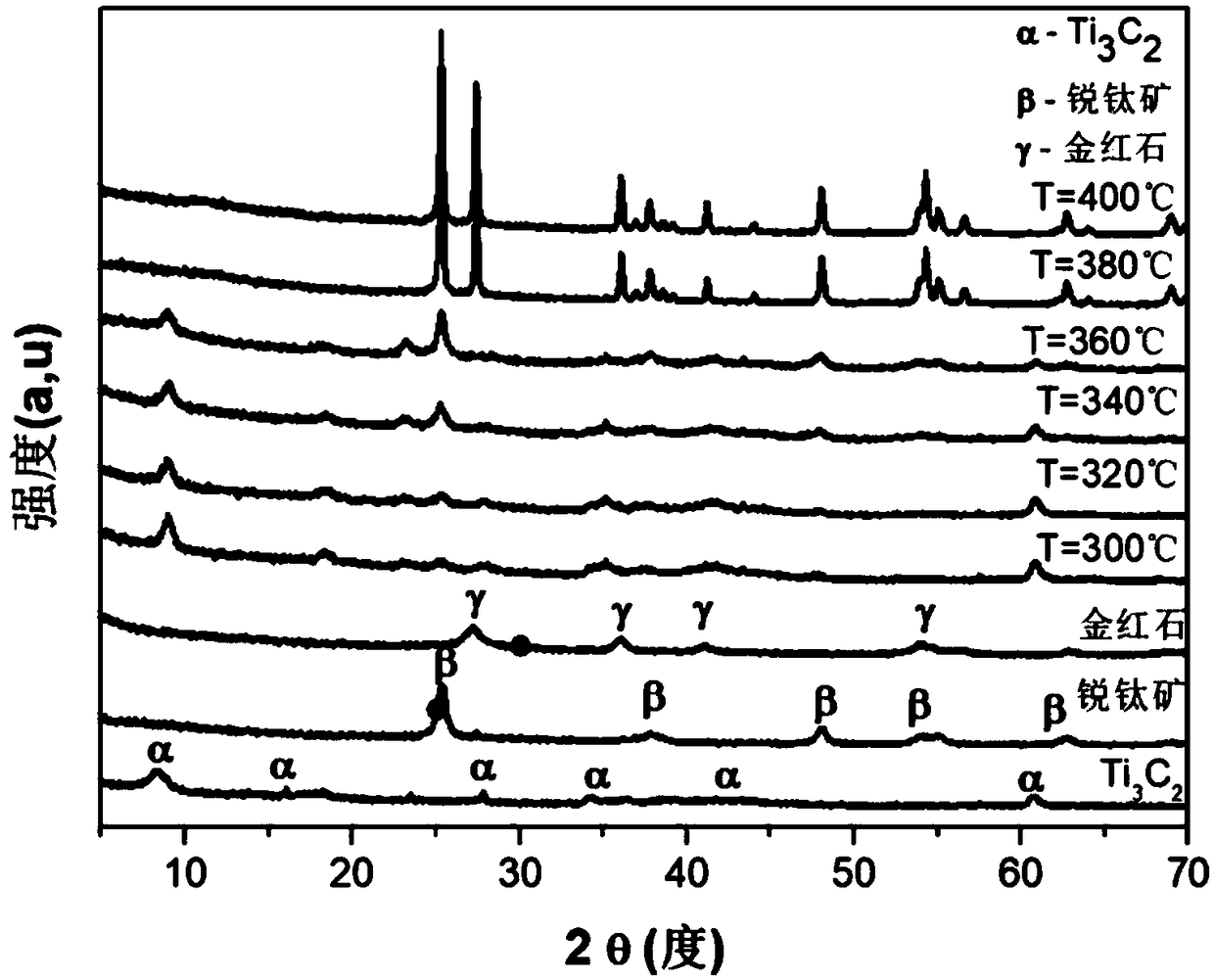

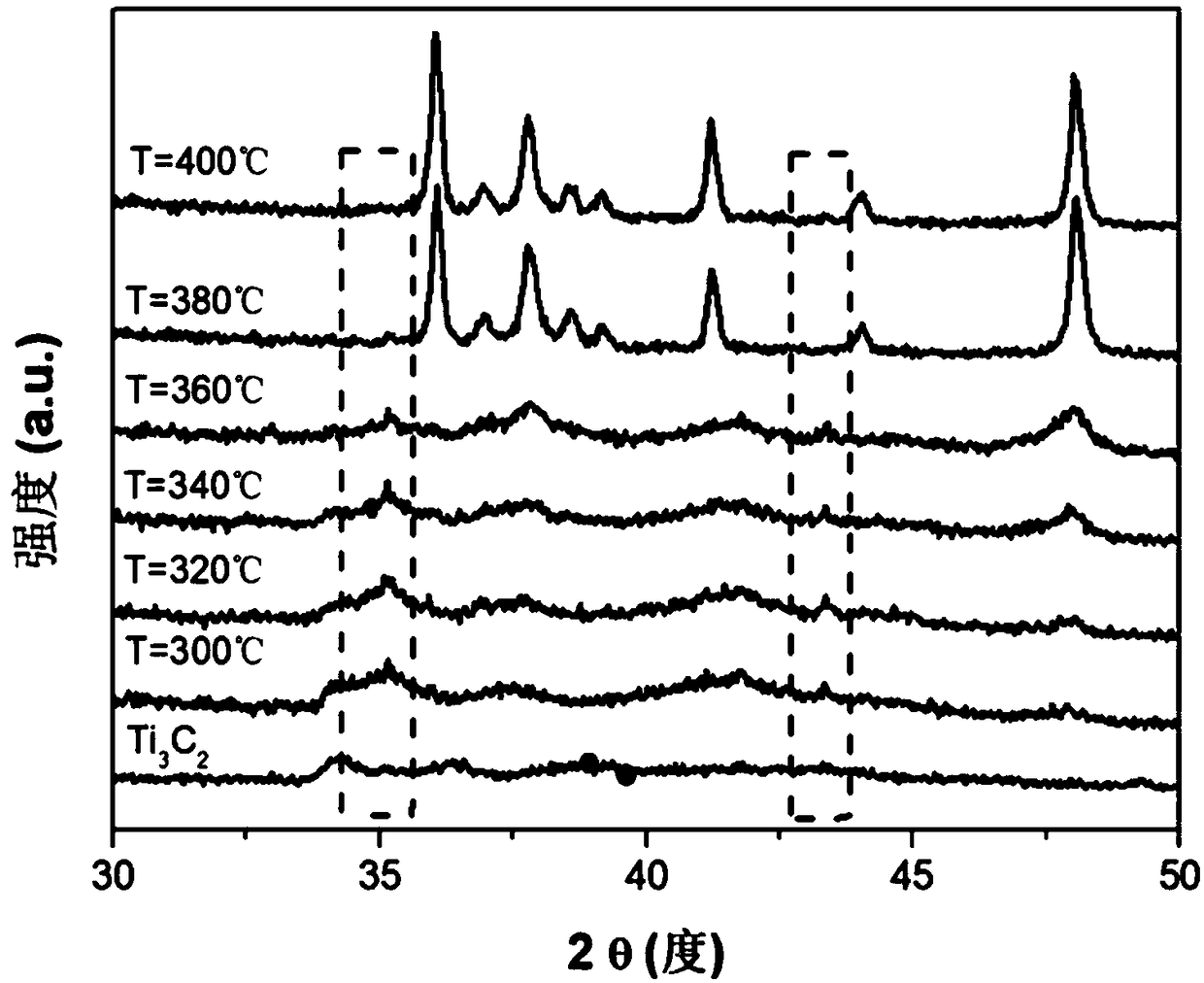

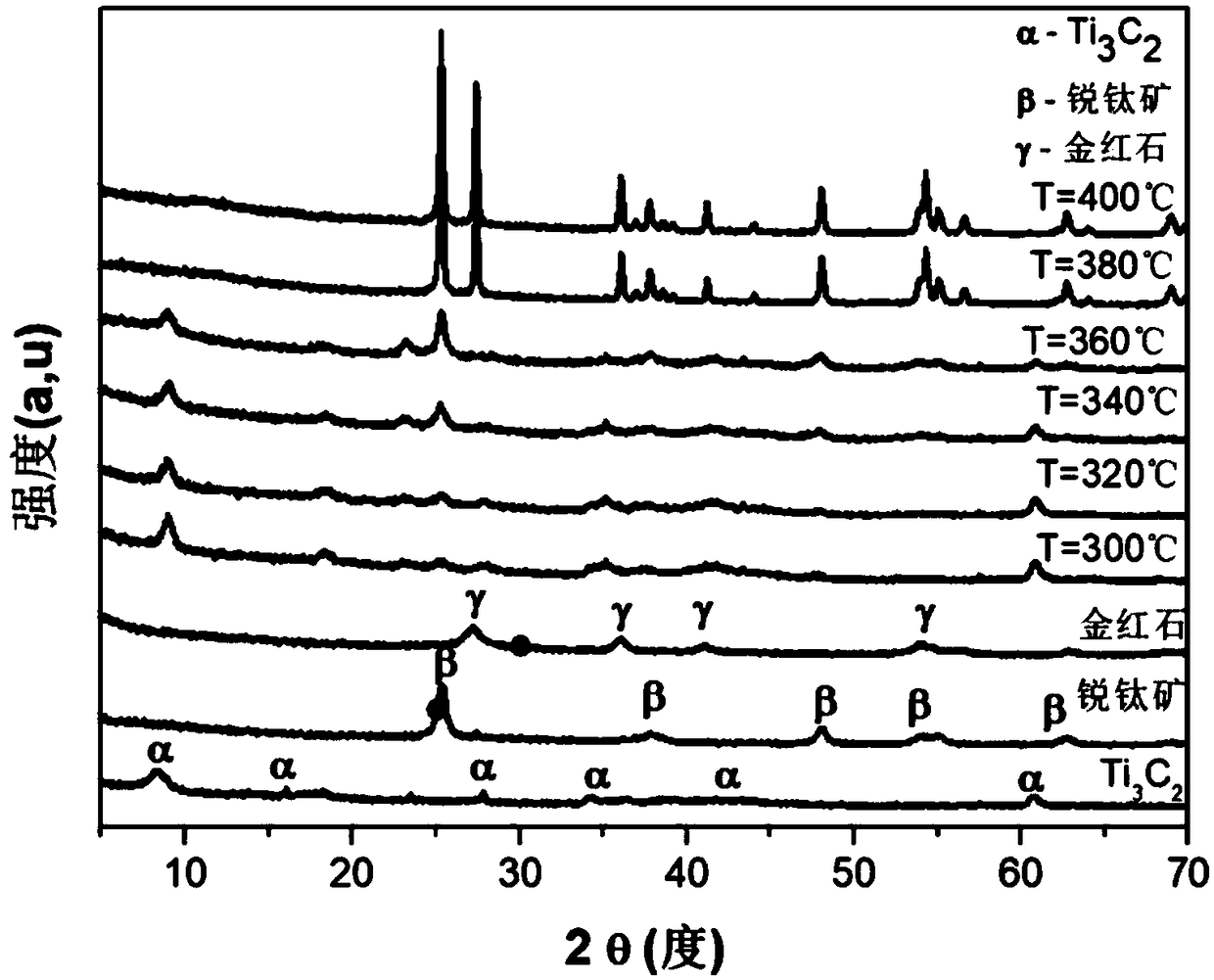

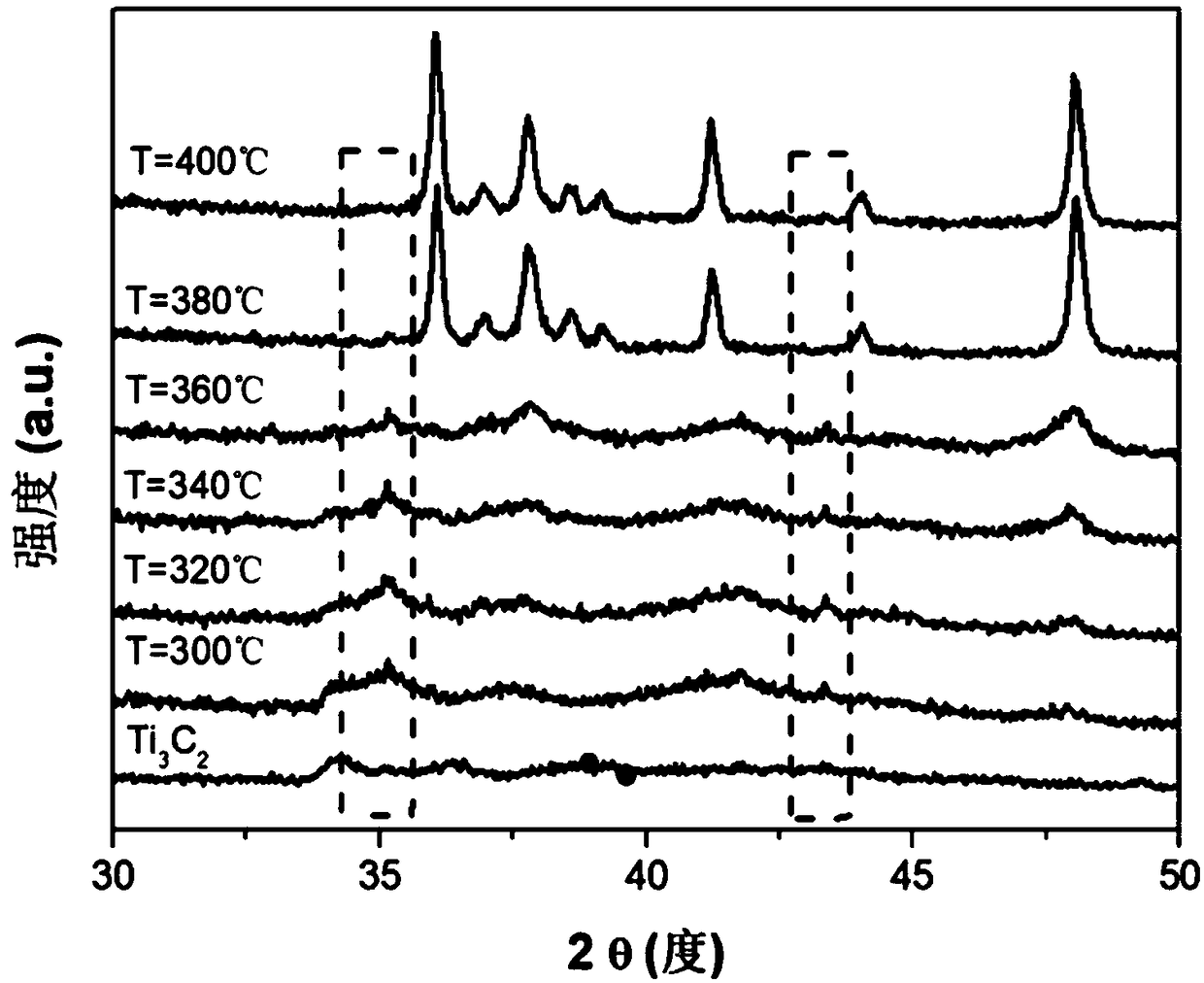

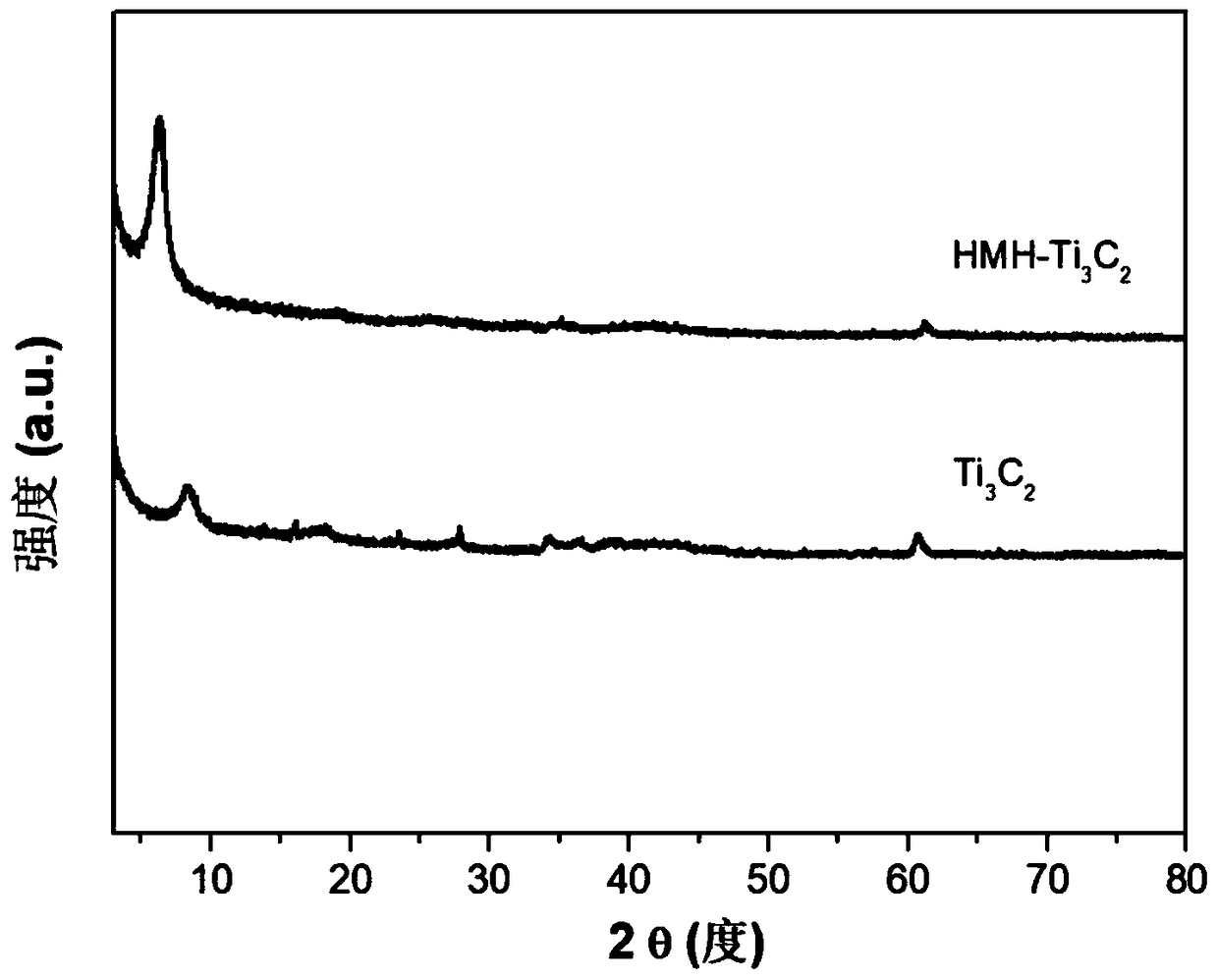

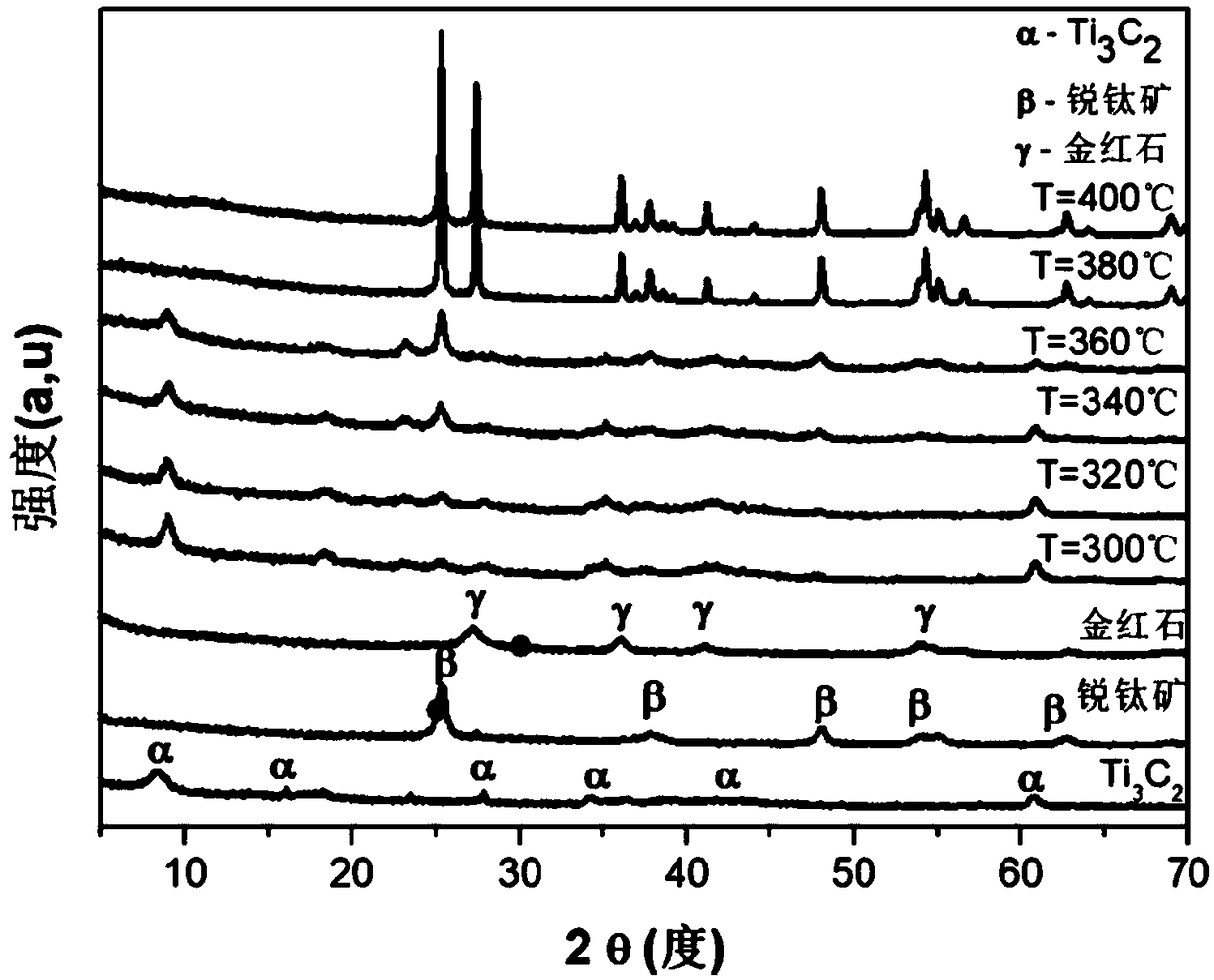

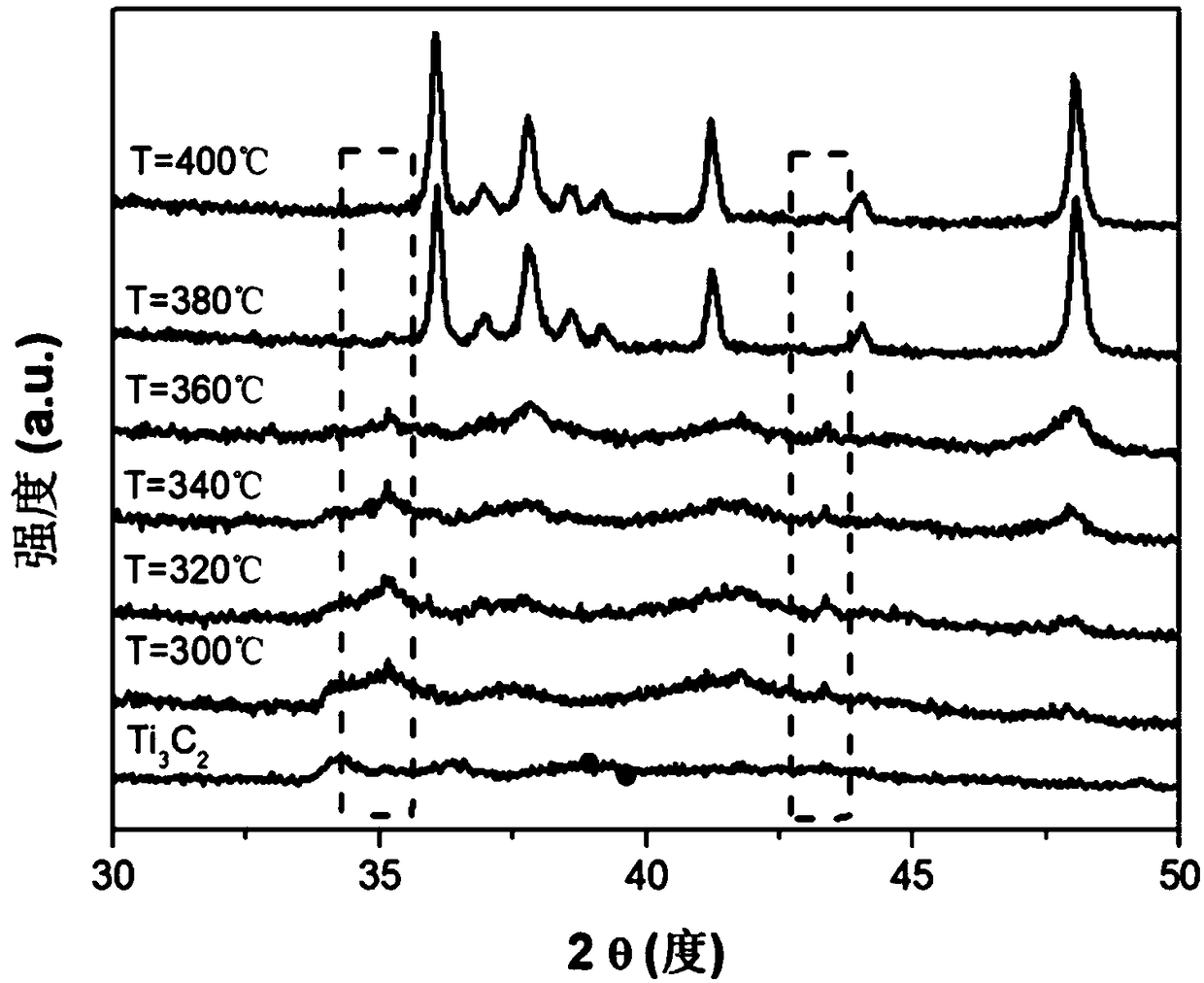

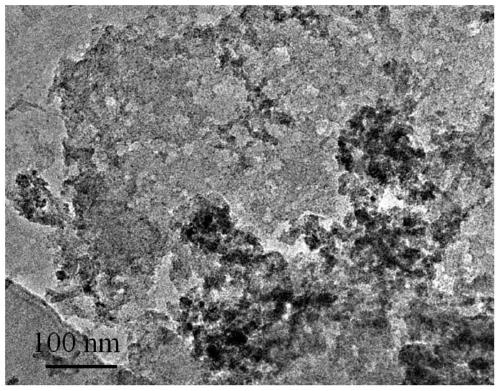

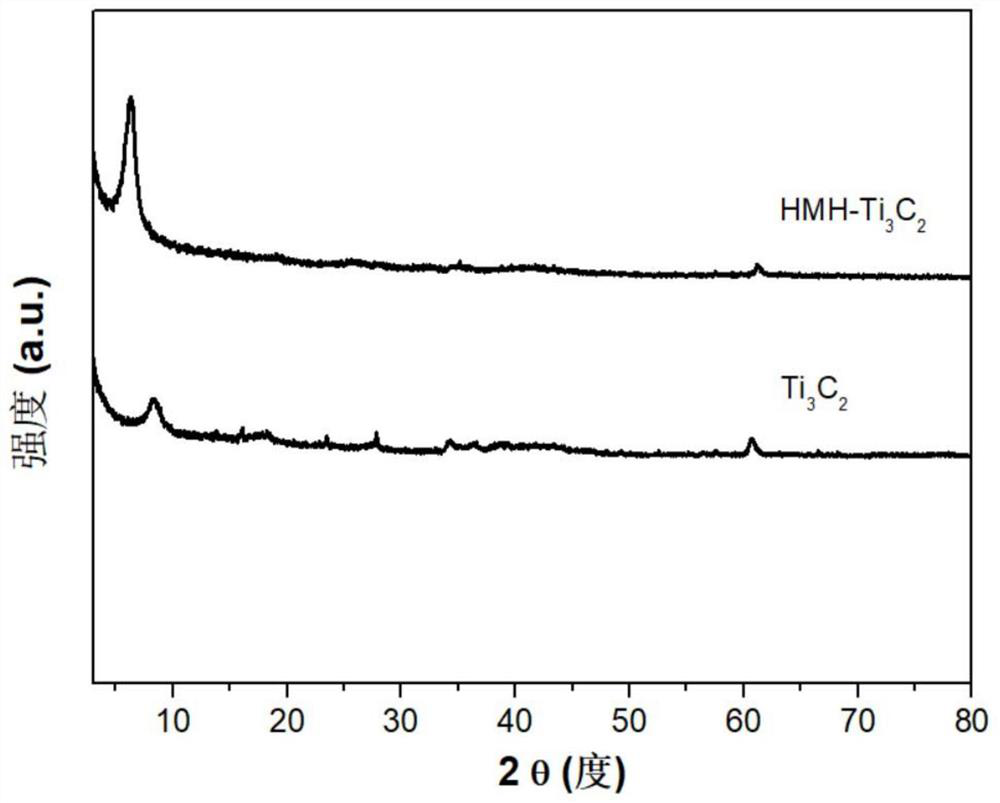

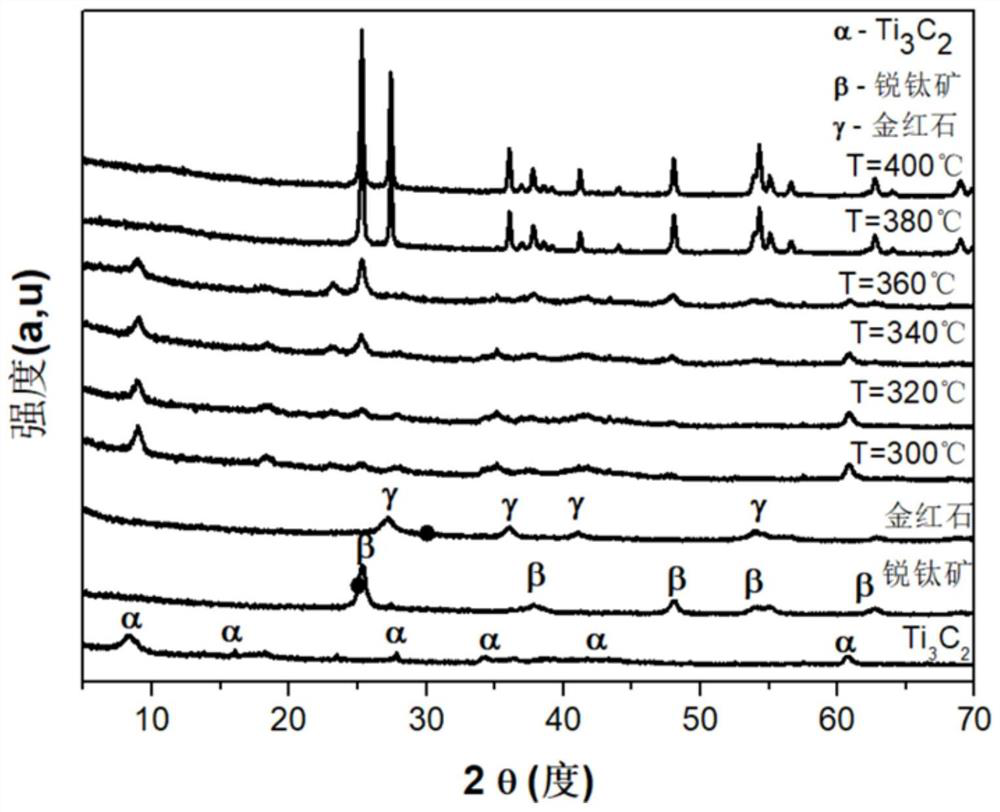

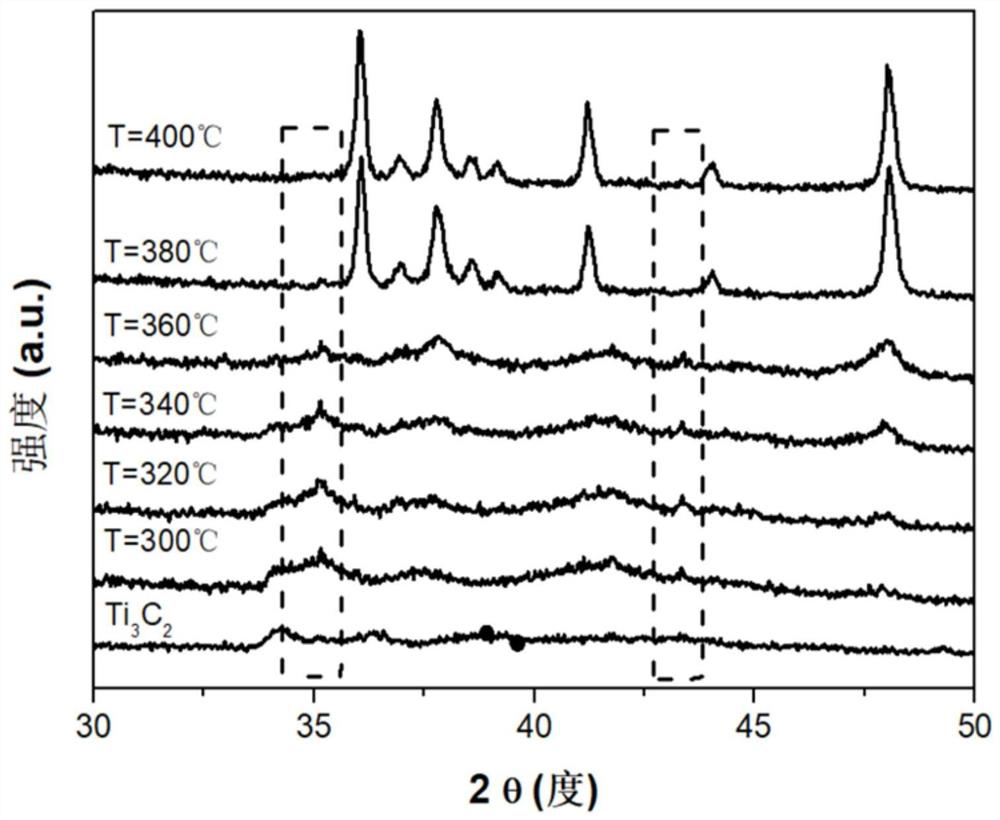

Method and product of in-situ synthetic TiO2@Ti3C2 by using dimethylsulfoxide intercalated and layered Ti3C2

InactiveCN109261180AIncrease layer spacingMultiple attachment sitesPhysical/chemical process catalystsArgon atmosphereOxygen

The invention relates to a method and product of in-situ synthetic TiO2@Ti3C2 by using dimethylsulfoxide intercalated and layered Ti3C2. The synthetic method comprises the following steps: 1) enablingTi3AlC2-MAX-phase ceramic powder to be dispersed in HF solution for etching, to obtain Mxene-Ti3C2; 2) enabling the Mxene-Ti3C2 to be dispersed in dimethylsulfoxide for performing dimethylsulfoxide intercalation, to obtain dimethylsulfoxide intercalated Ti3C2; 3) enabling the dimethylsulfoxide intercalated Ti3C2 to be dispersed in water, performing ultrasonic treatment in an argon atmosphere, after drying, to obtain dimethylsulfoxide intercalated and layered Ti3C2; and 4) performing in-situ oxidation on the dimethylsulfoxide intercalated and layered Ti3C2 in an oxygen condition, to obtain TiO2@Ti3C2. The method is capable of improving an interlayer spacing distance of the Mxene-Ti3C2 by using the dimethylsulfoxide and the ultrasonic treatment, providing more attachment sites for the generated TiO2, and more advantageously performing catalytic degradation on a pollutant.

Owner:ZHEJIANG UNIV

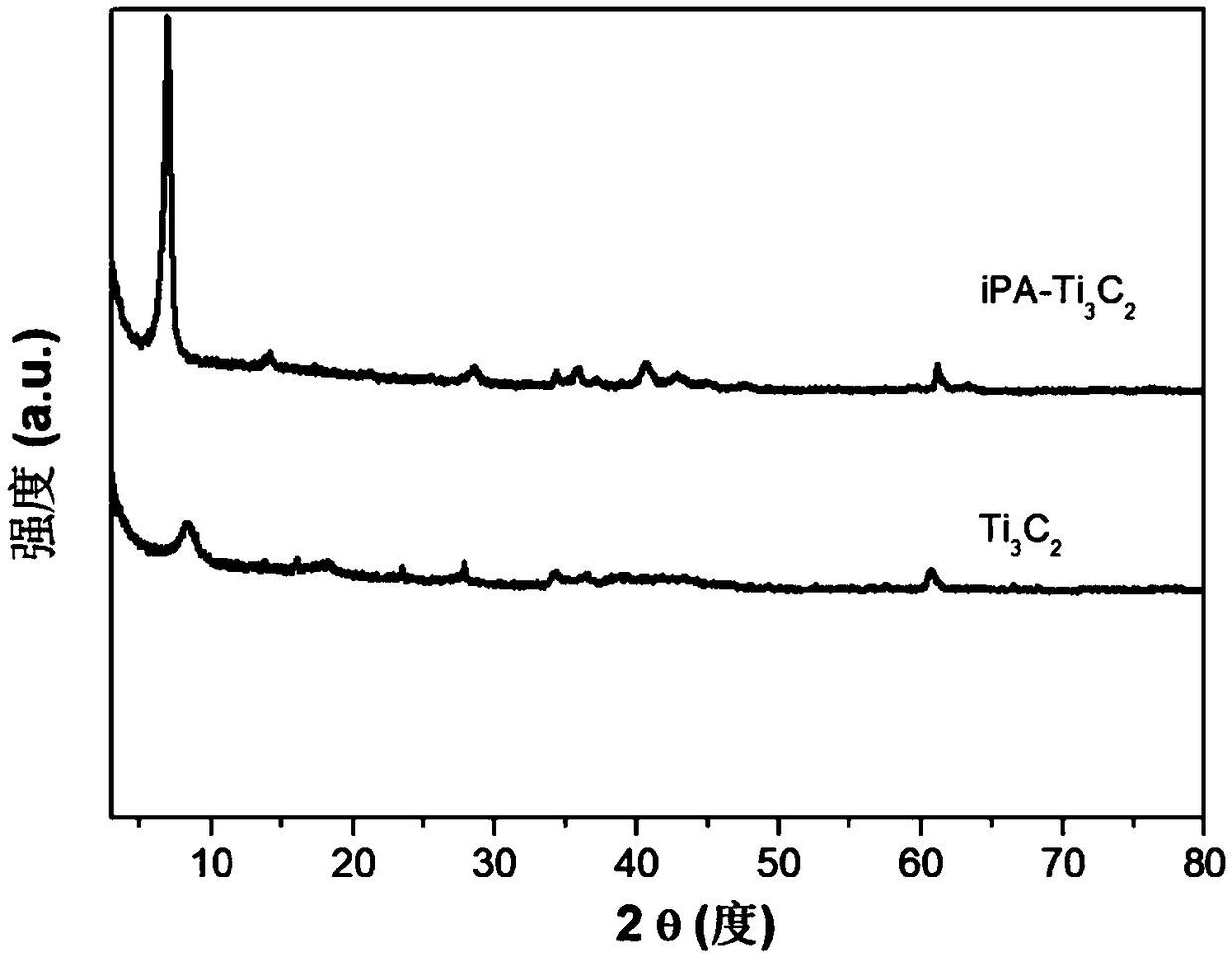

Method and product of in-situ synthetic TiO2@Ti3C2 by using isopropylamine intercalated and layered Ti3C2

InactiveCN109261181AHigh crystallinity and purityIncrease layer spacingPhysical/chemical process catalystsPollutantIsopropylamine

The invention relates to a method and product of in-situ synthetic TiO2@Ti3C2 by using isopropylamine intercalated and layered Ti3C2. The synthetic method comprises the following steps: 1) enabling Ti3AlC2-MAX-phase ceramic powder to be dispersed in HF solution for etching, to obtain Mxene-Ti3C2; 2) enabling the Mxene-Ti3C2 to be dispersed in mixed liquid of isopropylamine and water for performingisopropylamine intercalation, to obtain isopropylamine intercalated Ti3C2; 3) enabling the isopropylamine intercalated Ti3C2 to be dispersed in the water, performing ultrasonic treatment in an argonatmosphere, after drying, to obtain isopropylamine intercalated and layered Ti3C2; and 4) performing in-situ oxidation on the isopropylamine intercalated and layered Ti3C2 in an oxygen condition, to obtain TiO2@Ti3C2. The method is capable of improving an interlayer spacing distance of the Mxene-Ti3C2 by using the isopropylamine and the ultrasonic treatment, providing more attachment sites for thegenerated TiO2, and more advantageously performing catalytic degradation on a pollutant.

Owner:ZHEJIANG UNIV

Method for in situ synthesis of TiO2@Ti3C2 through intercalation and layering of hydrazine hydrate and product

ActiveCN109225290AHigh crystallinity and purityIncrease layer spacingPhysical/chemical process catalystsPollutantEnvironmental chemistry

The invention relates to a method for in situ synthesis of TiO2@Ti3C2 through the intercalation and layering of hydrazine hydrate and a product. The synthetic method comprises the following steps: (1)dispersing Ti3AlC2-MAX-phase ceramic powder into an HF solution, and etching, so as to obtain Mxene-Ti3C2; (2) dispersing Mxene-Ti3C2 into hydrazine hydrate, carrying out hydrazine hydrate intercalation, so as to obtain hydrazine hydrate intercalated Ti3C2; (3) dispersing hydrazine hydrate intercalated Ti3C2 into water, carrying out ultrasonic treatment in an argon atmosphere, and drying, so as to obtain hydrazine hydrate intercalated and layered Ti3C2; and (4) carrying out in situ oxidation on hydrazine hydrate intercalated and layered Ti3C2, so as to obtain TiO2@Ti3C2. According to the method, the interlayer spacing of Mxene-Ti3C2 is increased through hydrazine hydrate and ultrasonic treatment, so that more attachment sites are provided for generated TiO2, and the catalytic degradationof pollutants is promoted.

Owner:ZHEJIANG UNIV

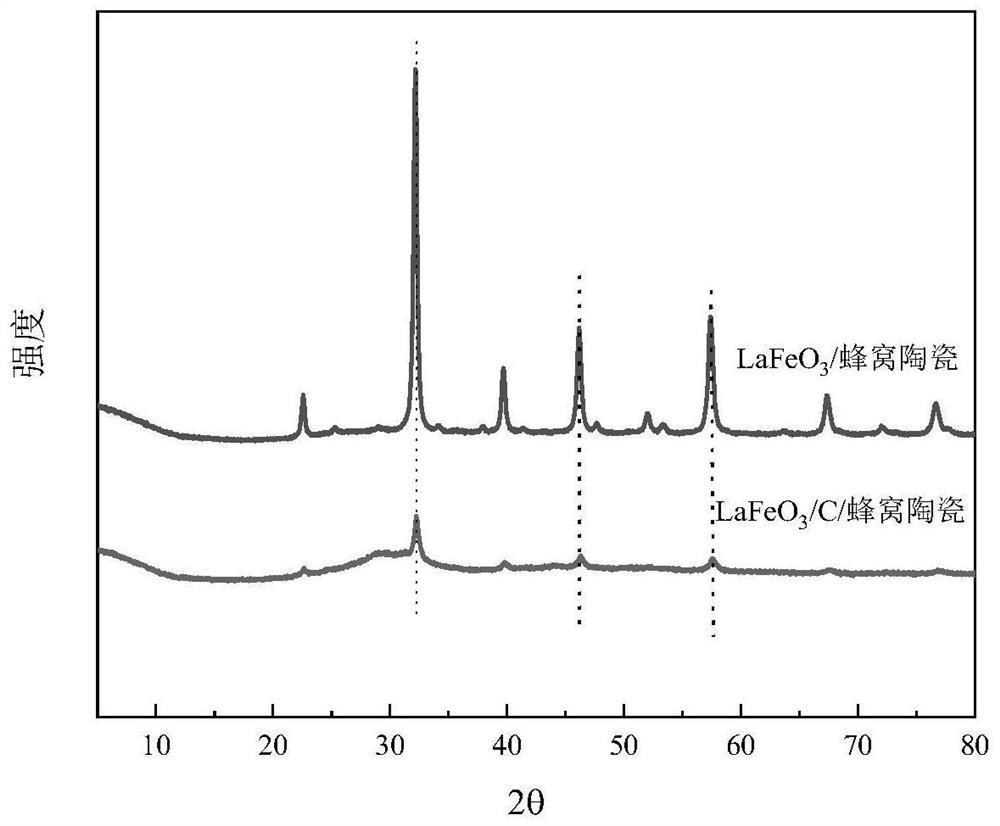

Preparation method and application of honeycomb ceramic/biochar film/rare earth perovskite monolithic catalyst

PendingCN113976130AAvoid the disadvantages of easy falling off and large particlesEasy accessDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCatalytic oxidation

The invention belongs to the field of environmental protection, and particularly relates to a honeycomb ceramic / biochar film / rare earth perovskite monolithic catalyst and a preparation method and application thereof. Agricultural and forestry waste biomass is utilized to form a biochar film second carrier layer on the surface of honeycomb ceramic, and perovskite oxide is indirectly coated on a honeycomb ceramic carrier to form the monolithic catalyst; on one hand, the specific surface area of the carrier is favorably increased, and more attachment sites are provided for the active component; on the other hand, the effect of fixing the active components can be achieved, the effect of inhibiting aggregation and grain growth of the active components is facilitated, meanwhile, part of carbon elements are doped into crystal lattices of perovskite, defects are caused, and the low-temperature catalytic oxidation activity of the catalyst is improved. Moreover, the biochar is developed in pore structure, and has a large number of defects and unsaturated bonds on the surface. Oxygen and other heteroatoms are easily adsorbed on the defects to form a plurality of functional groups such as carboxyl, anhydride and carbonyl, so that the catalytic oxidation degradation of VOCs (Volatile Organic Compounds) is promoted.

Owner:CHANGZHOU UNIV

Preparation method of self-supporting three-dimensional porous carbon negative electrode material

InactiveCN110061236AImprove conductivityIncrease capacityCell electrodesSecondary cellsPorous carbonSolvent

The invention discloses a preparation method of a self-supporting three-dimensional porous carbon negative electrode material. The preparation method comprises the following steps: dissolving saccharose into an acetone and deionized water mixed solvent to obtain a precursor solution; after mixing a foamed nickel self-supporting body and a precursor, carrying out a hydrothermal reaction, naturallycooling to room temperature, and washing and drying the product; and carrying out heat treatment on the product in an inert atmosphere so as to obtain a final product. A three-dimensional porous carbon material is grown on the surface in an in-situ mode by taking metal foamed nickel as the self-supporting body. In the subsequent heat treatment process, the part connected with metal nickel can be partially graphitized through the catalytic graphitization of metal nickel, so that the electron conductivity is improved. Moreover, the material is of relatively large specific surface area through the three-dimensional porous structure, the material can be in sufficient contact with an electrode material, more attachment sites are provided for sodium ions, and the material is of relatively high capacity. According to the method, the used raw materials are stable in ingredients and wide in resources, the technological operation is simple, the prepared electrode does not need a subsequent coating technology, the capacity loss is reduced, and the method is beneficial for industrial production.

Owner:SHAANXI UNIV OF SCI & TECH

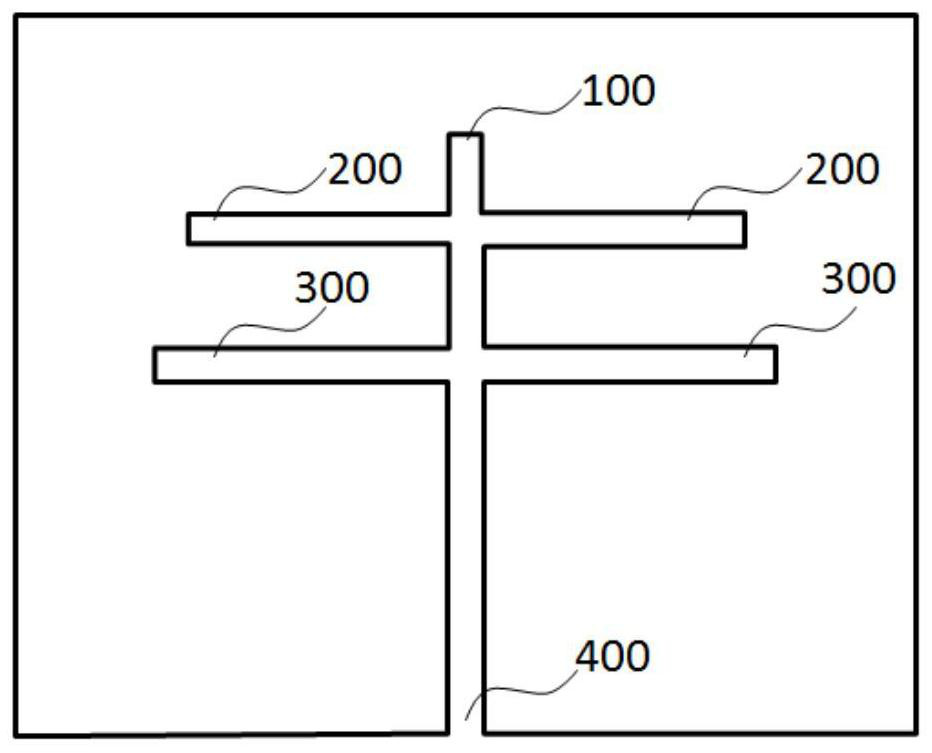

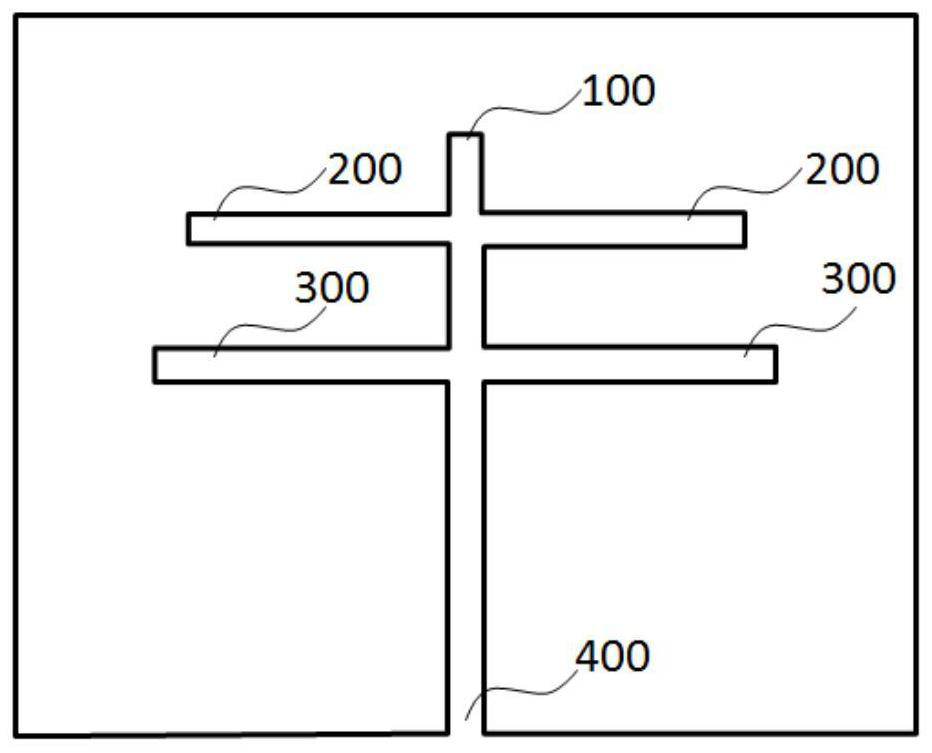

Array type positive electrode current collector for liquid metal battery

ActiveCN110890549AImprove the uniformity of positive electrode interface distributionEliminate the risk of short circuitsElectrode carriers/collectorsSecondary cellsBattery chargeElectrical battery

The invention discloses an array type positive electrode current collector for a liquid metal battery. By arranging a columnar array pointing to the direction of a negative electrode at the bottom ofa positive electrode current collector shell, the distribution uniformity of the positive electrode interface of the liquid metal battery is effectively improved, the internal stress of an interface alloy layer is reduced, more attachment sites are provided for the alloy layer, and the short-circuit risk in the operation process of a large-size battery is effectively eliminated, at the same time,the mass transfer process of the battery charging and discharging process can be effectively ensured, and the safe, stable and efficient battery operation is promoted.

Owner:WUHAN UNIV

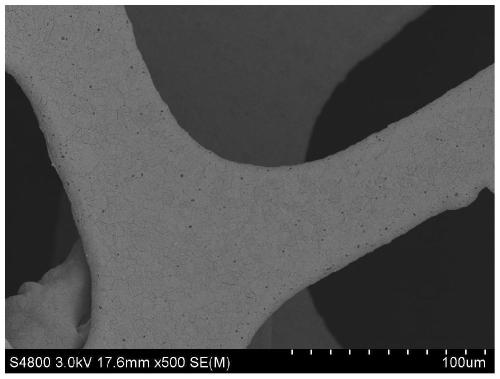

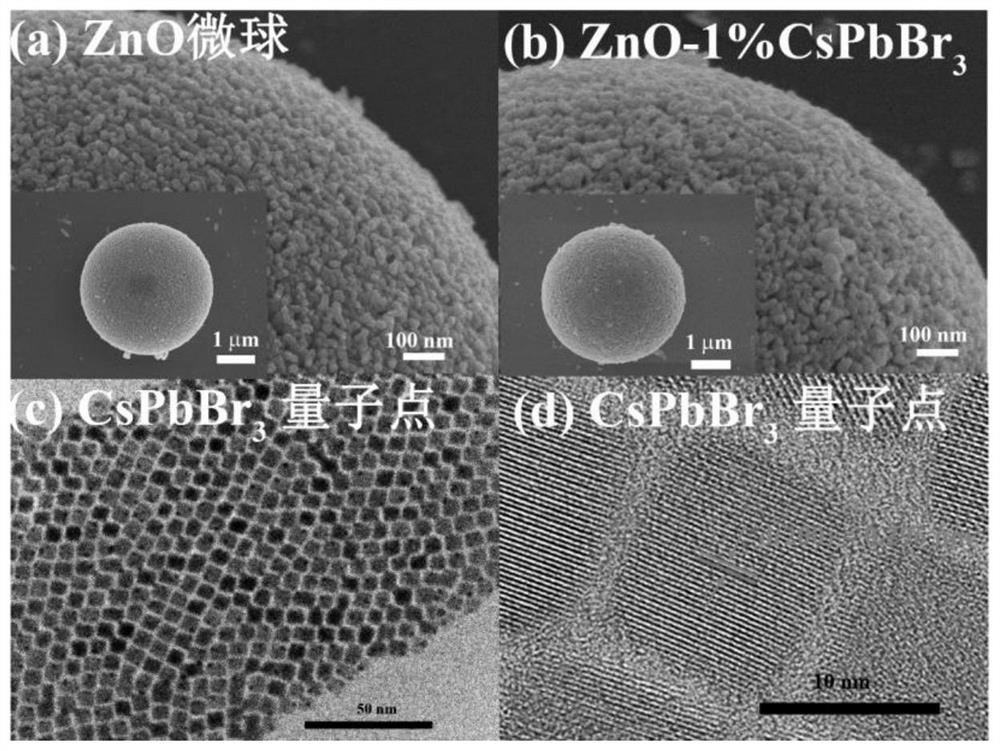

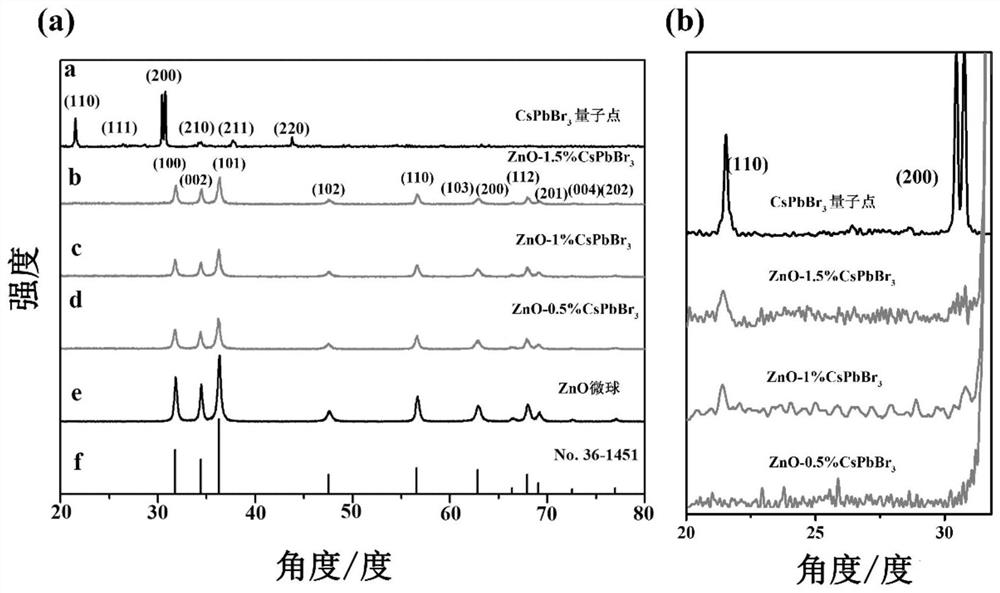

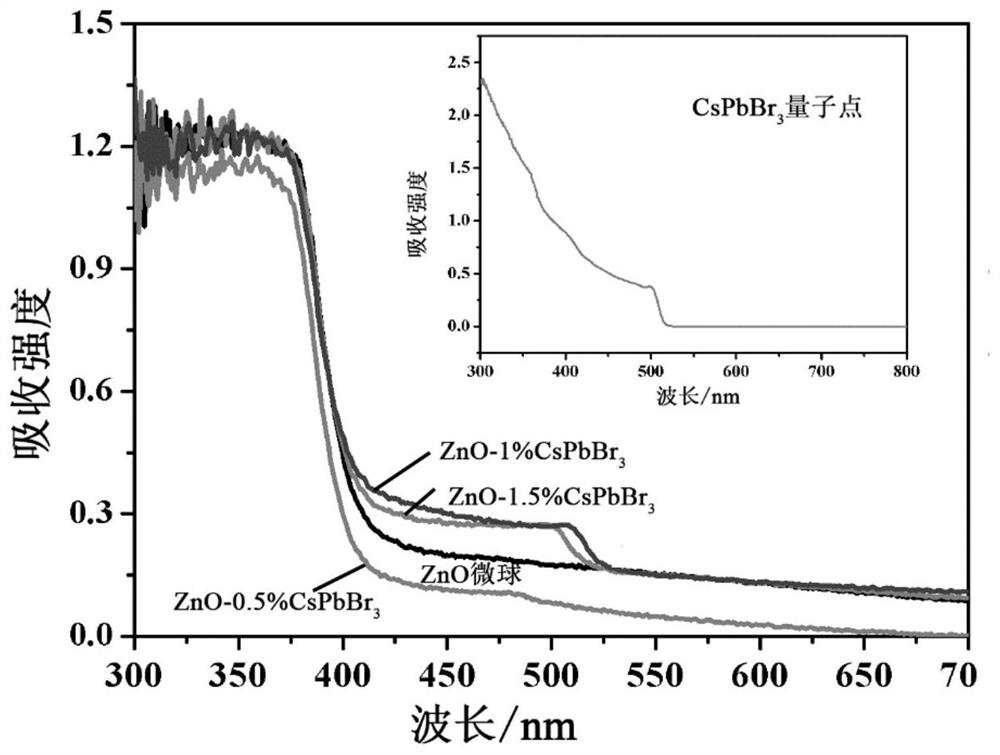

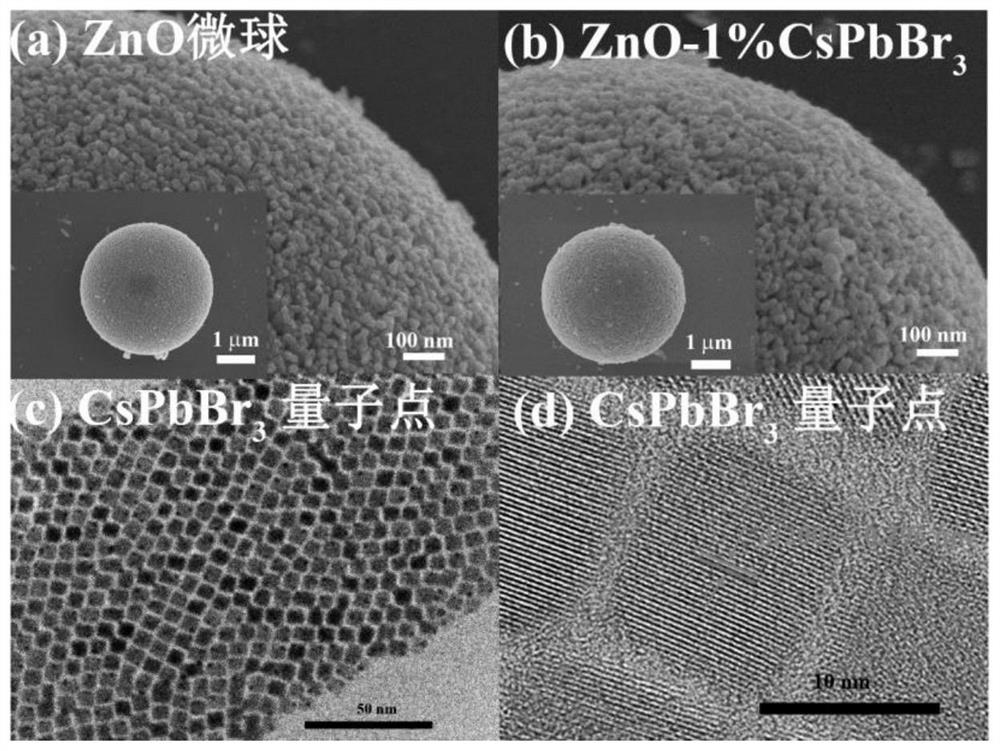

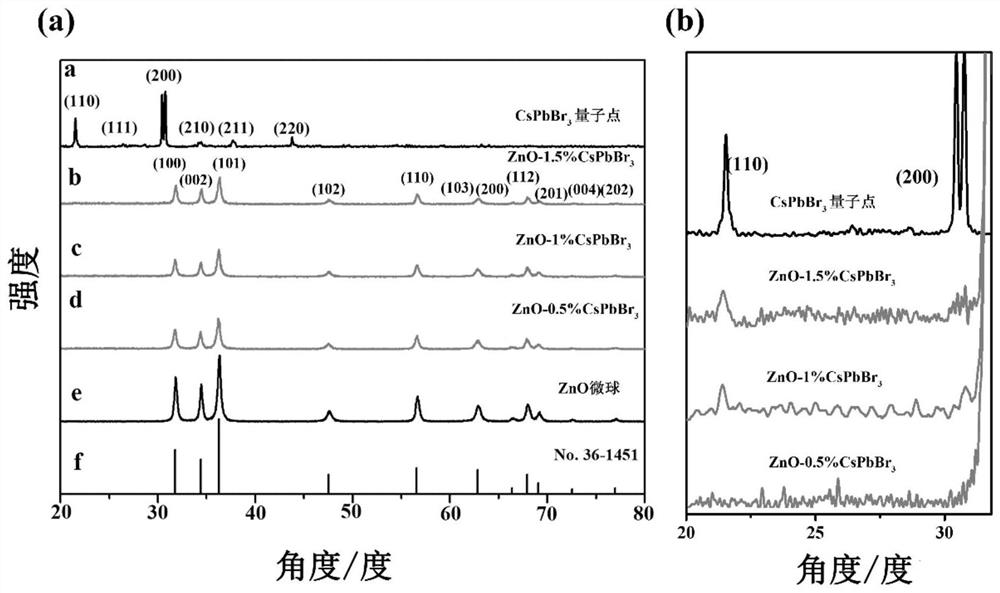

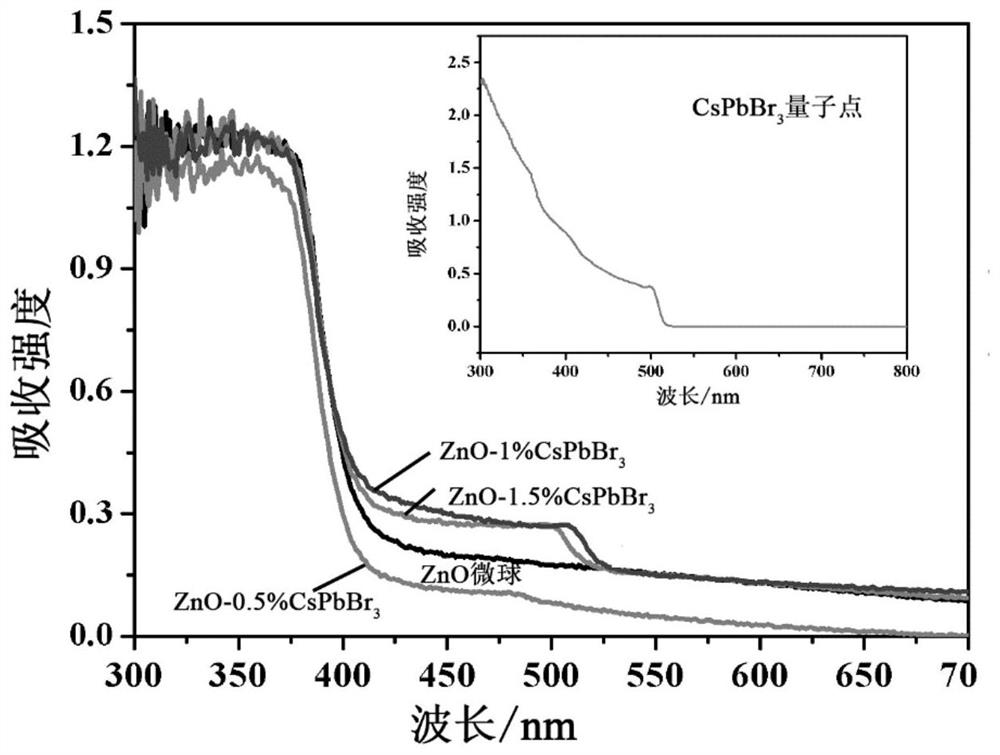

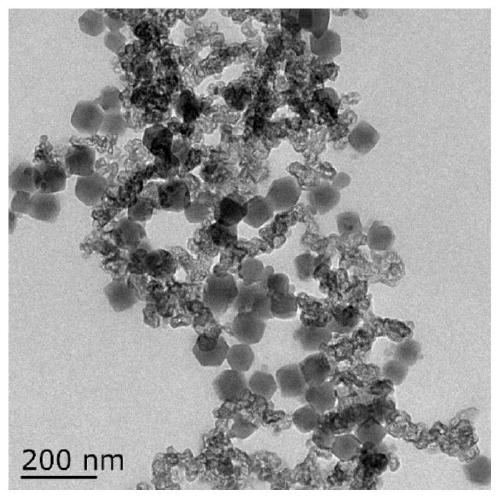

Room-temperature NO2 sensor based on ZnO microsphere and CsPbBr3 quantum dot composite material and preparation method thereof

ActiveCN112683963AThe synthesis method is simpleLow costMaterial resistanceChemistryComposite material

The invention discloses a room-temperature NO2 sensor based on a ZnO microsphere and CsPbBr3 quantum dot heterostructure composite material and a preparation method thereof, and belongs to the technical field of semiconductor oxide gas sensors. The sensor is composed of a ceramic chip substrate with a metal interdigital electrode and a ZnO microsphere and CsPbBr3 quantum dot heterostructure composite material sensitive layer coating the metal interdigital electrode. The morphology of zinc oxide is of a sphere structure, has a large specific surface area, and can provide more attachment sites, so that zinc oxide is in full contact with perovskite CsPbBr3 quantum dots with small sizes, and a gas sensitive element with good gas sensitive response and high response recovery speed is obtained. In addition, the CsPbBr3 quantum dots are used as an excellent photoelectric material and can absorb visible light, so that more photon-generated carriers are provided. The sensor provided by the invention adopts a planar structure, and is simple in process, short in manufacturing period and suitable for mass production.

Owner:JILIN UNIV

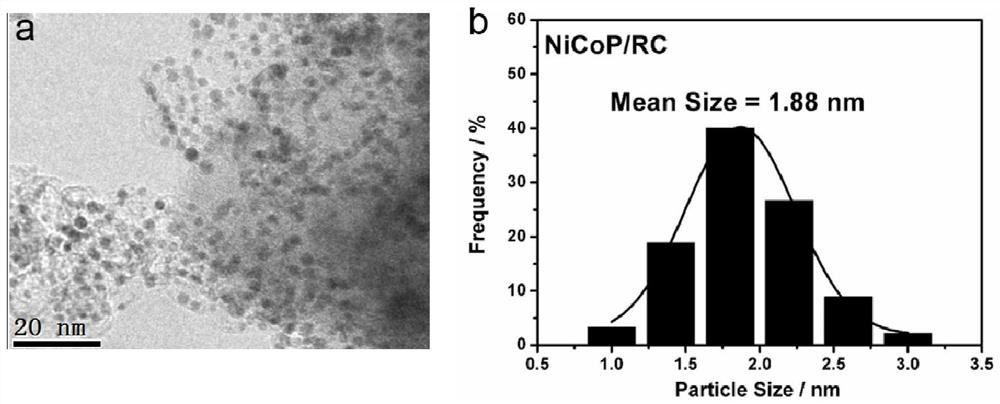

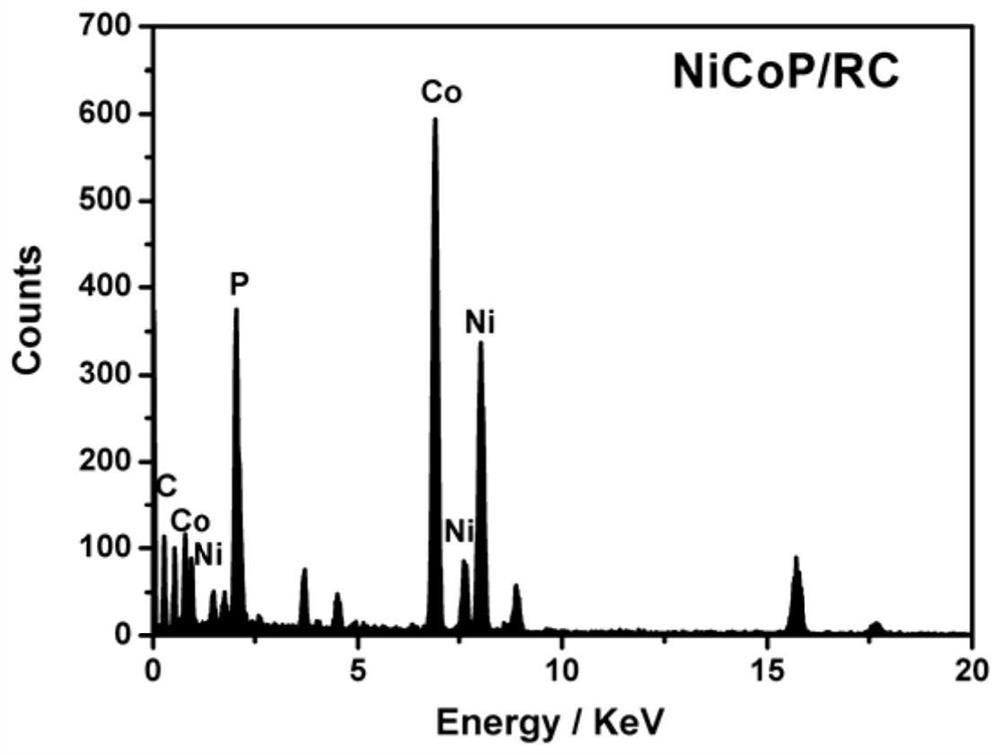

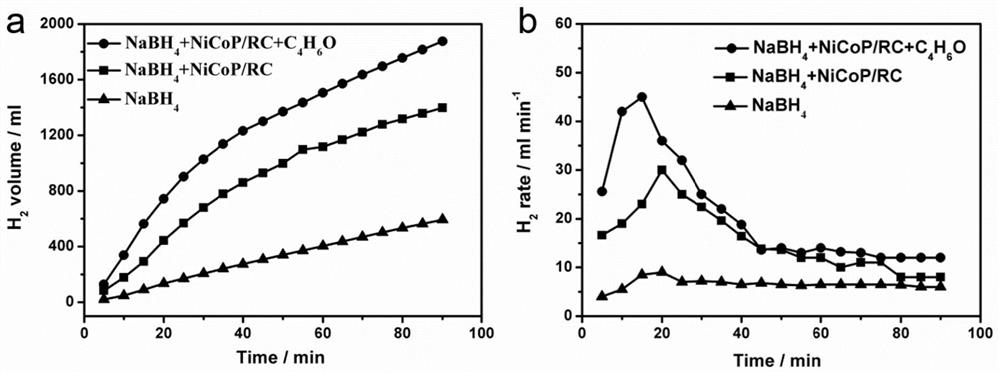

Hydrogen production catalyst by hydrolysis of sodium borohydride, preparation method and application thereof

ActiveCN111330604BNo pollutionThe preparation method is mildOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen productionPtru catalystPhosphoric acid

The invention discloses a hydrogen production catalyst by hydrolysis of sodium borohydride, a preparation method and an application thereof, belonging to the field of catalyst synthesis. In the preparation method of the present invention, the phosphoramidate chelating resin is used as a carrier to load Ni, Co or NiCoP composite active components, and nickel ions, cobalt ions or both enter into the phosphoramidate chelating resin inside by electrostatic attraction and group force. In the pores, and strongly coordinate with the nitrogen-containing ligands, so that they are distributed and fixed inside the resin, forming stable resin-nickel ions, resin-cobalt ions, resin-cobalt ions / nickel ion complexes; heat treatment of the above complexes , nickel ions, cobalt ions or a mixture of the two loaded on the aminophosphoric acid chelating resin form Ni with phosphorus source 2 P. Co. 2 P or NiCoP compound, and itself is carbonized to change the carbon support. The preparation method of the invention has mild conditions, low cost and high yield, is beneficial to industrialized production, and does not cause environmental pollution.

Owner:XI AN JIAOTONG UNIV

Room temperature no based on quantum dot composites 2 Sensor and its preparation method

ActiveCN112683963BThe synthesis method is simpleLow costMaterial resistanceMicrospherePerovskite (structure)

A based on ZnO microspheres and CsPbBr 3 Room temperature NO of quantum dot heterostructure composites 2 A sensor and a preparation method thereof belong to the technical field of semiconductor oxide gas sensors. A ceramic substrate with metal interdigitated electrodes and ZnO microspheres and CsPbBr coated on the metal interdigitated electrodes 3 Composition of sensitive layer of quantum dot heterostructure composite material. The morphology of zinc oxide is a sphere structure, which has a large specific surface area and can provide more attachment sites, so that it can be combined with the smaller perovskite CsPbBr 3 The quantum dots are in full contact, so that a gas sensor with better gas sensor response and faster response recovery speed can be obtained. In addition, CsPbBr 3 As an excellent photoelectric material, quantum dots can absorb visible light, thereby providing more photogenerated carriers. The sensor of the present invention adopts a planar structure, has simple process, short production period, and is suitable for mass production.

Owner:JILIN UNIV

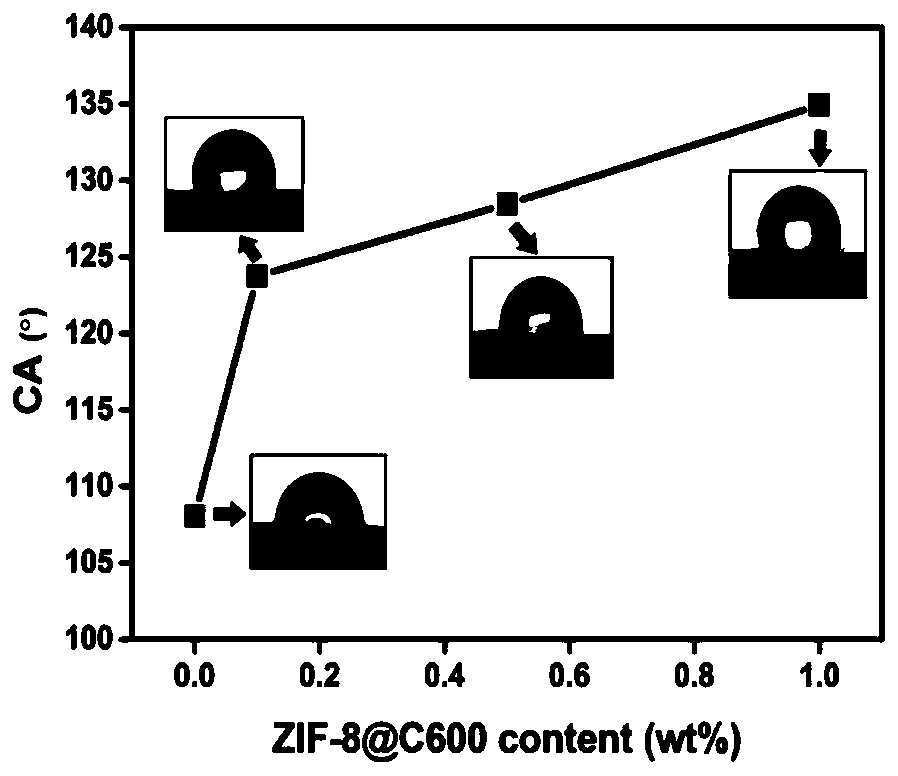

Polylactic acid/zif-8@c600 composite material and its preparation method and application

ActiveCN109135220BGood dispersionEasy reunionOther chemical processesMonocomponent polyesters artificial filamentElectrospinningOil water

The invention discloses a polylactic acid / ZIF-8@C600 composite material and a preparation method and application thereof. The composite material is prepared from polylactic acid and ZIF-8@C600 composite nano modifier which are carbon black particles with ZIF-8 loaded on the surfaces in the mass ratio of (99.9-99.0):(0.1-1.0). Accordingly, a solution blending method is adopted, a polylactic solution and ultrasonic dispersion liquid of dichloromethane of the ZIF-8@C600 composite nano modifier are blended in proportion, and the composite material is obtained through an electrospinning method. Thehydrophobic property and oil absorbency of the composite material are obviously improved, and meanwhile the oil-water separation performance is achieved; in addition, the product is biodegradable, safe, reliable, free of peculiar smell and low in damage and pollution degree to the human body and environment.

Owner:NANJING UNIV OF SCI & TECH

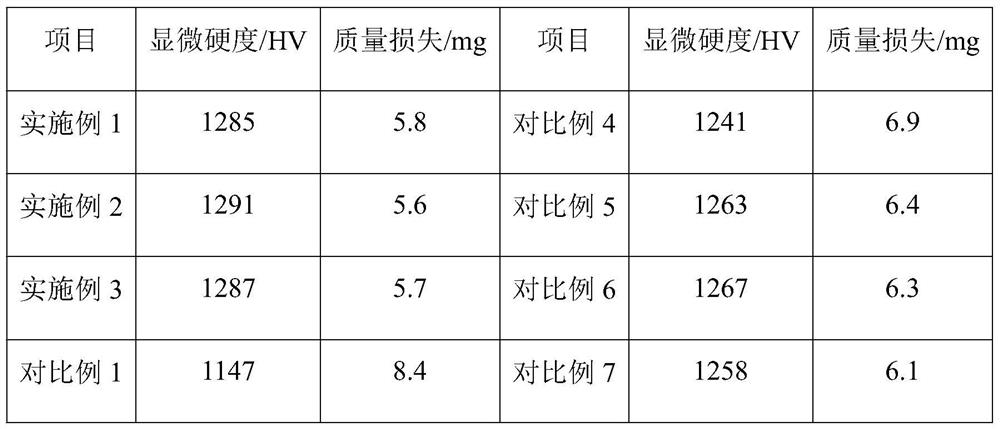

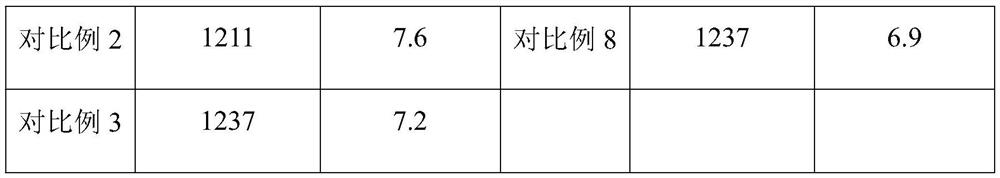

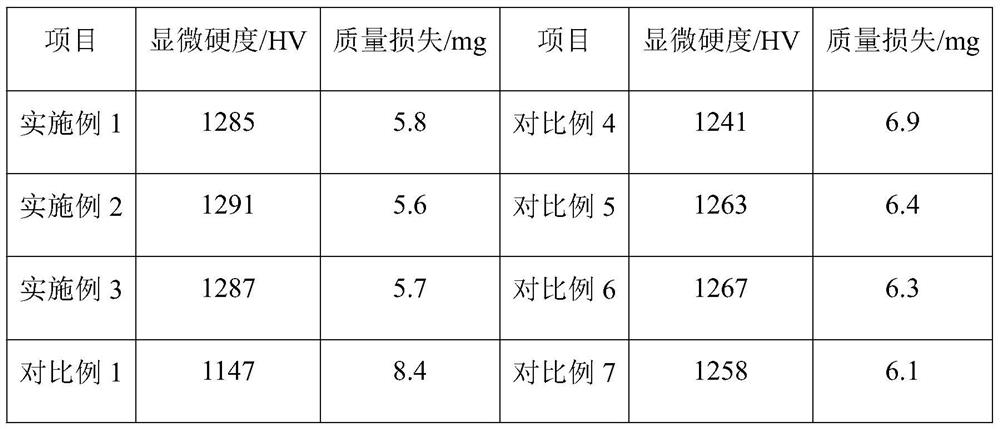

A high-strength wear-resistant closed steel frame and its processing technology

ActiveCN113215566BImprove wear resistanceReduce porosityLiquid/solution decomposition chemical coatingCleaning processes and apparatusSurface oxidationSteel frame

The invention discloses a high-strength wear-resistant closed steel frame and its processing technology. During the preparation, the surface of the alloy steel pipe fitting is cleaned by laser, and the surface of the alloy steel pipe fitting is cleaned by laser to remove the oxide film on the surface to improve the surface. Wettability, in the subsequent laser cladding process, the cladding liquid can be fully spread, and the subsequent wear-resistant layer is more uniform and dense, with fewer pores and better wear resistance; at the same time, the surface of the alloy steel will form a rough structure after laser cleaning , can improve its surface roughness, and further improve the adhesion of the thick laser cladding layer, so as to improve the comprehensive wear resistance of alloy steel. The process design of the application is reasonable, and the operation is simple. The prepared alloy steel pipe fittings form a wear-resistant layer on the surface, and the steel frame is obtained by splicing and installing. The wear-resistant layer can effectively improve the wear resistance and comprehensive mechanical properties of the alloy steel frame. The alloy steel frame It can be applied to multiple technical fields and has high practicability.

Owner:常州市天河电器有限公司

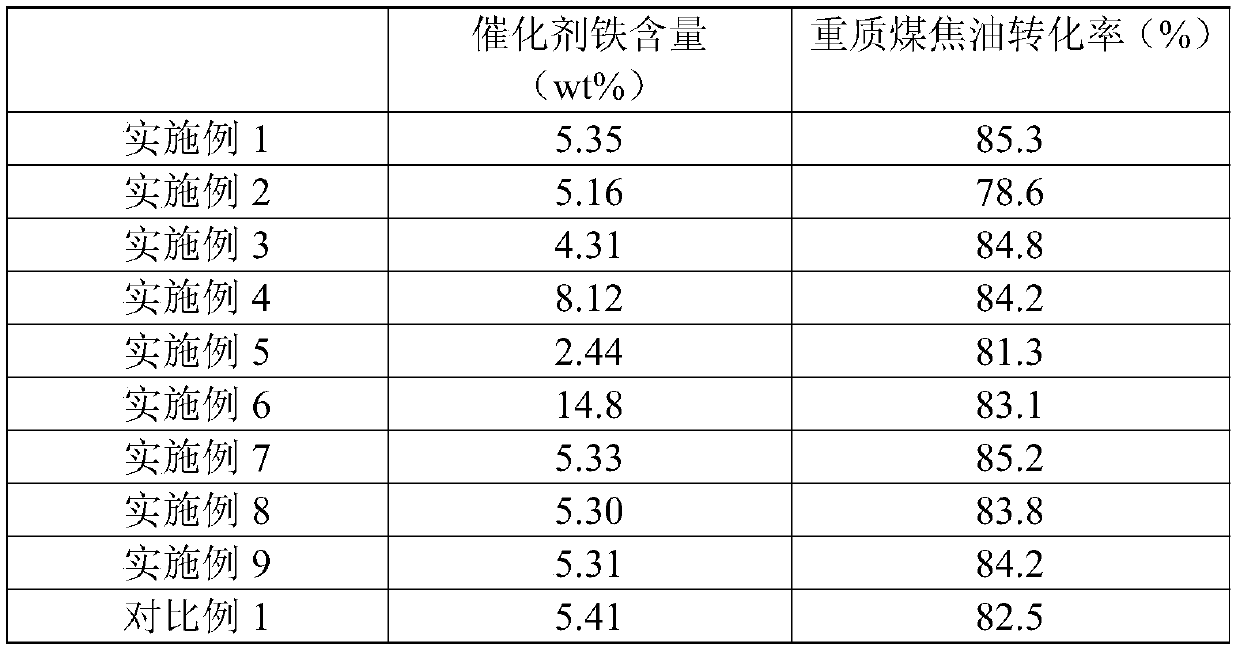

Suspension bed hydrogenation catalyst and preparation method and application thereof

ActiveCN110270331AShorten the timeLarge specific surface areaCatalyst activation/preparationHydrocarbon oil crackingFerrous saltsWater soluble

The invention relates to a suspension bed hydrogenation catalyst and a preparation method and application thereof. The method comprises the steps that water-soluble ferrous salt is loaded on a carrier, and then a hydrogen peroxide solution is adopted for oxidation treatment to obtain the catalyst; by adopting hydrogen peroxide for oxidation treatment, compared with a traditional air oxidation method, the time required for preparing the catalyst is shortened by 90-99.5%, the activity of the prepared catalyst is also remarkably improved, the catalyst obtained by means of the method is adopted for a hydrogenation lightweight reaction of heavy coal tar in a 500ml high-pressure reactor, and the conversion rate of the heavy coal tar can reach 81% or more.

Owner:胜帮科技股份有限公司

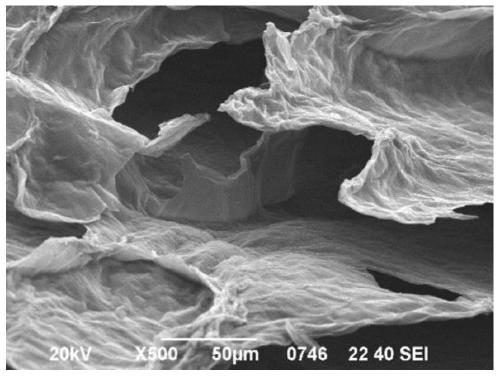

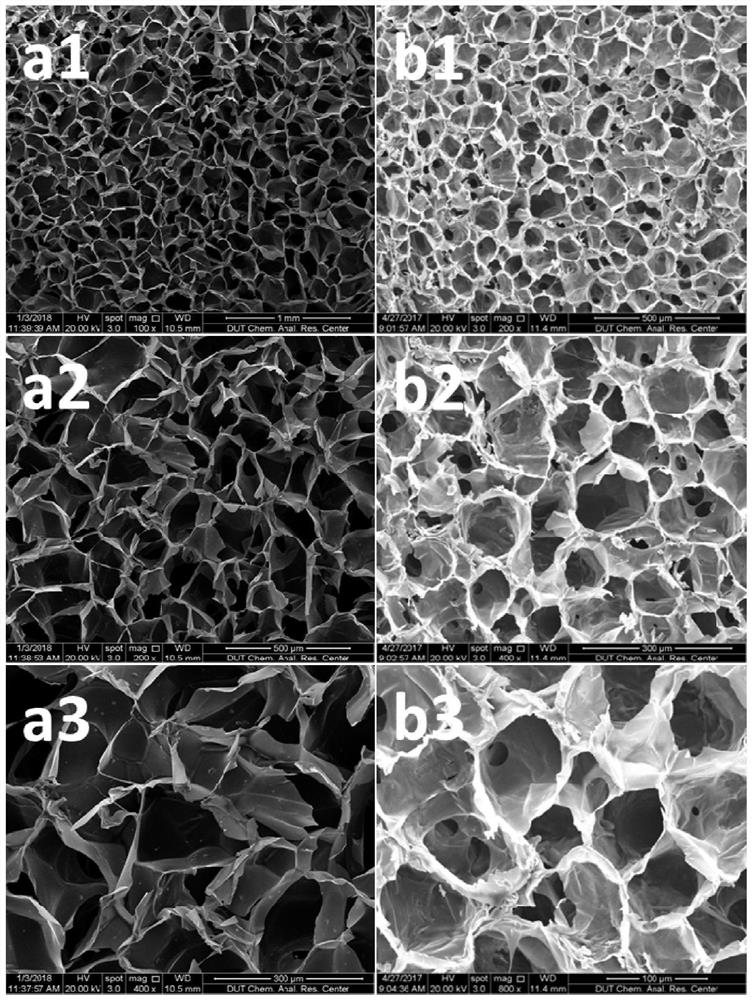

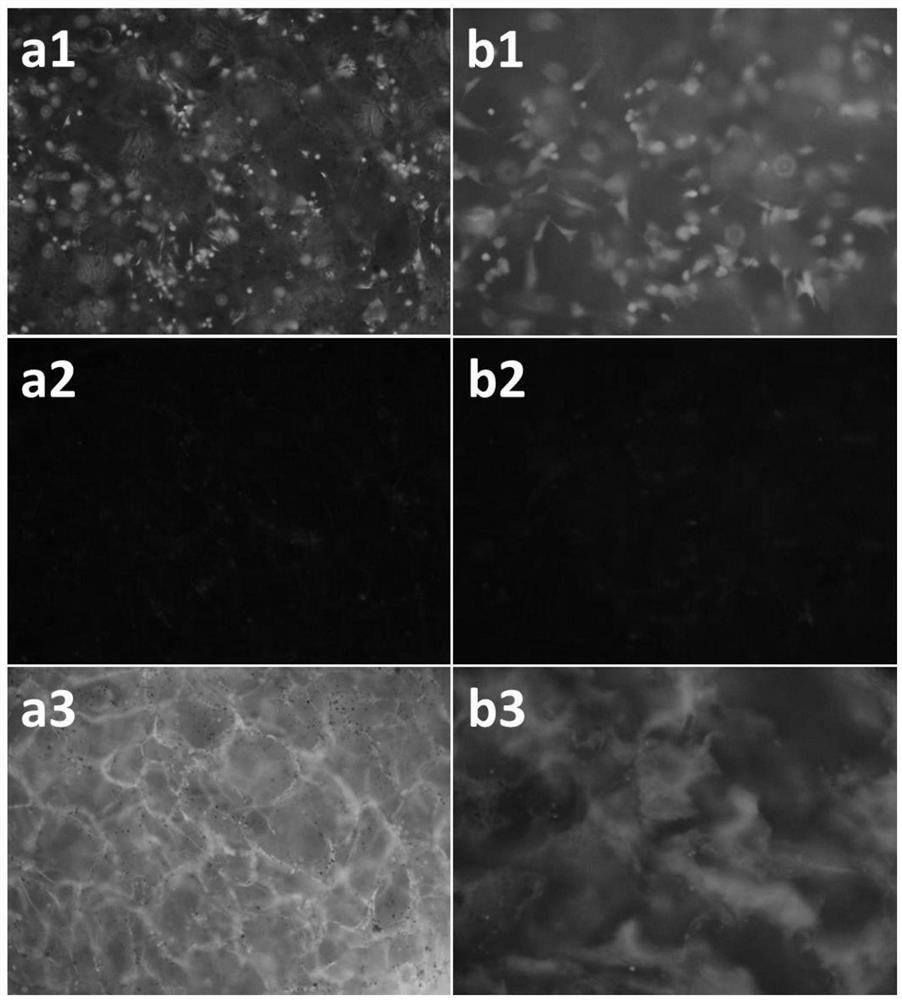

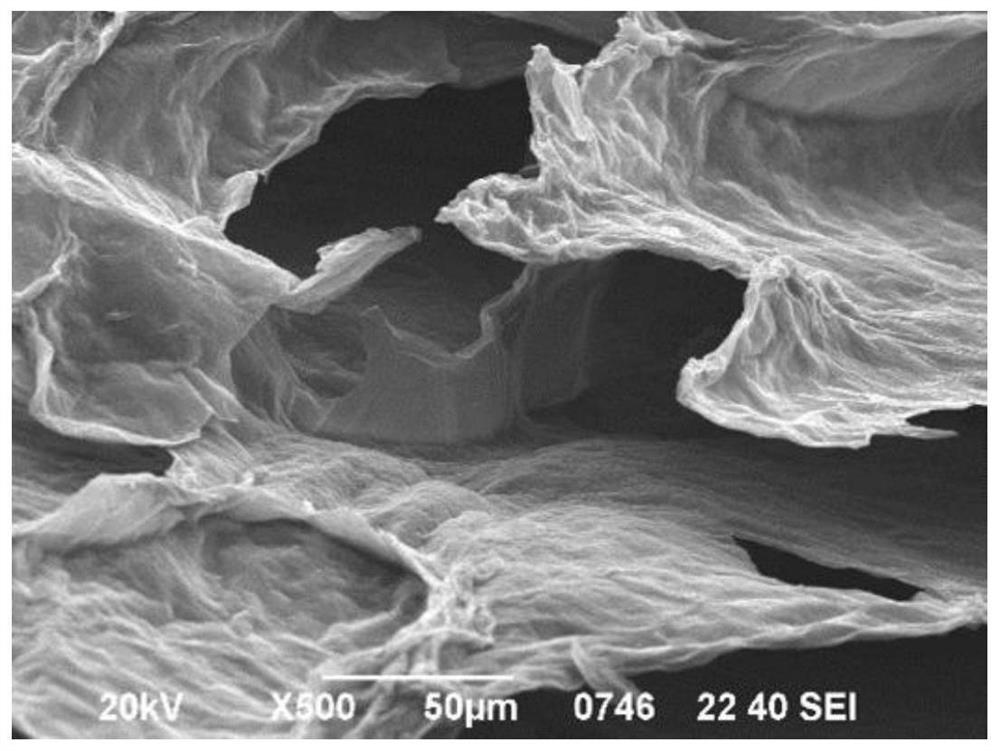

Bionic composite scaffold material doped with graphene and establishment method of bionic composite support material

InactiveCN108273139AGuaranteed water absorptionGuaranteed biocompatibilityTissue regenerationProsthesisDoped grapheneFreeze-drying

The invention belongs to the field of tissue engineering scaffold materials, and provides a bionic composite scaffold material doped with graphene and an establishment method of the bionic composite support material. The establishment method comprises the following steps: firstly preparing a Cs acetic acid solution, a GP aqueous solution, a Gel aqueous solution and a graphene suspension, and thenmixing the Cs acetic acid solution and the GP aqueous solution to prepare a Cs / GP solution A; adding the Gel aqueous solution into the Cs / GP solution A to prepare a Cs / GP / Gel solution B; and adding the graphene suspension into the Cs / GP / Gel solution B to prepare a Cs / GP / Gel / Gr solution C, transferring the solution C into a low-temperature mold, freeze drying at a low temperature, and performing the subsequent treatment, thus obtaining the bionic cartilage composite support material. A mass ratio of chitosan Cs to beta-sodium glycerophosphate GP to gelatin Gel to graphene Gr in the bionic cartilage composite scaffold material is 1: (5 to 20): (1 to 5): (0.02 to 0.08). The bionic composite scaffold material has the advantages of simple process, easy control and low production cost; and a produced support product is uniform in porosity, has an inter-connective pore structure and has an excellent bionic effect.

Owner:DALIAN UNIV OF TECH

A kind of processing method of high concentration p-nitrophenol

ActiveCN109694128BIncrease surface areaImprove stabilityOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsHigh concentrationPtru catalyst

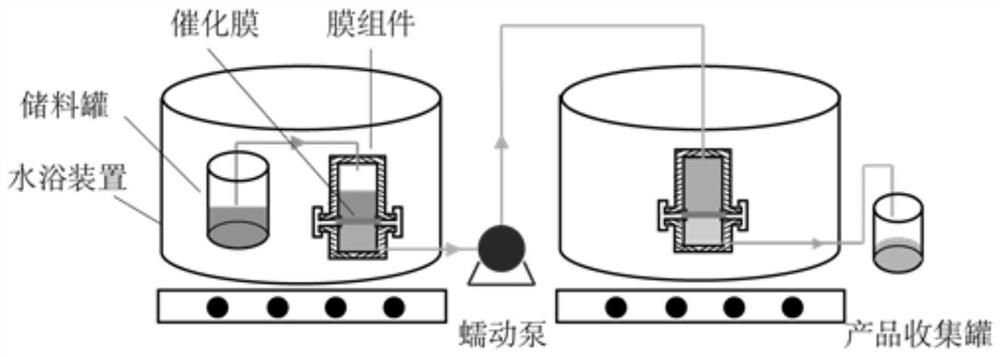

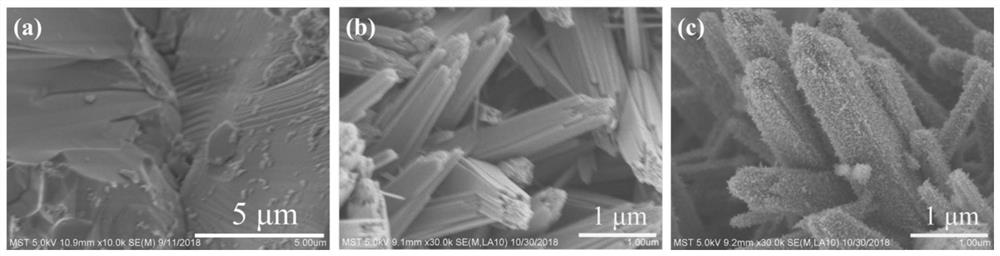

The invention relates to a method for treating high-concentration p-nitrophenol, which belongs to the technical field of catalysis. The method realizes the complete conversion of high-concentration p-nitrophenol through a flow-through reactor, and the key of the method is to prepare a catalytic membrane with excellent performance and construct a flow-through reactor. First, dendritic TiO is grown on the surface of the ceramic membrane and in the pores. 2 Nanorods, modified by silane coupling agent, loaded with Pd particles to prepare catalytic membrane. A flow-through reactor is constructed by utilizing the porous characteristics of the membrane, and the reaction liquid continuously flows through the pores of the membrane to fully contact and react with the active components, thereby realizing the continuous and complete conversion of high-concentration p-nitrophenol. The advantage of this invention is that dendritic TiO 2 Nanorods can increase the specific surface area of the film, thereby loading more Pd particles and improving catalytic activity; TiO 2 The branch can play the role of fixing the Pd particles; the Pd particles are supported on the surface of the membrane and in the pores, which avoids the problem of difficult subsequent separation of the catalyst and the product.

Owner:NANJING TECH UNIV

Micron hollow porous composite spherical sodium ion battery cathode material and preparation method thereof

ActiveCN111180689BImprove structural stabilityShorten the de-embedding pathSecondary cellsPositive electrodesElectrolytic agentElectrical battery

Owner:CENT SOUTH UNIV

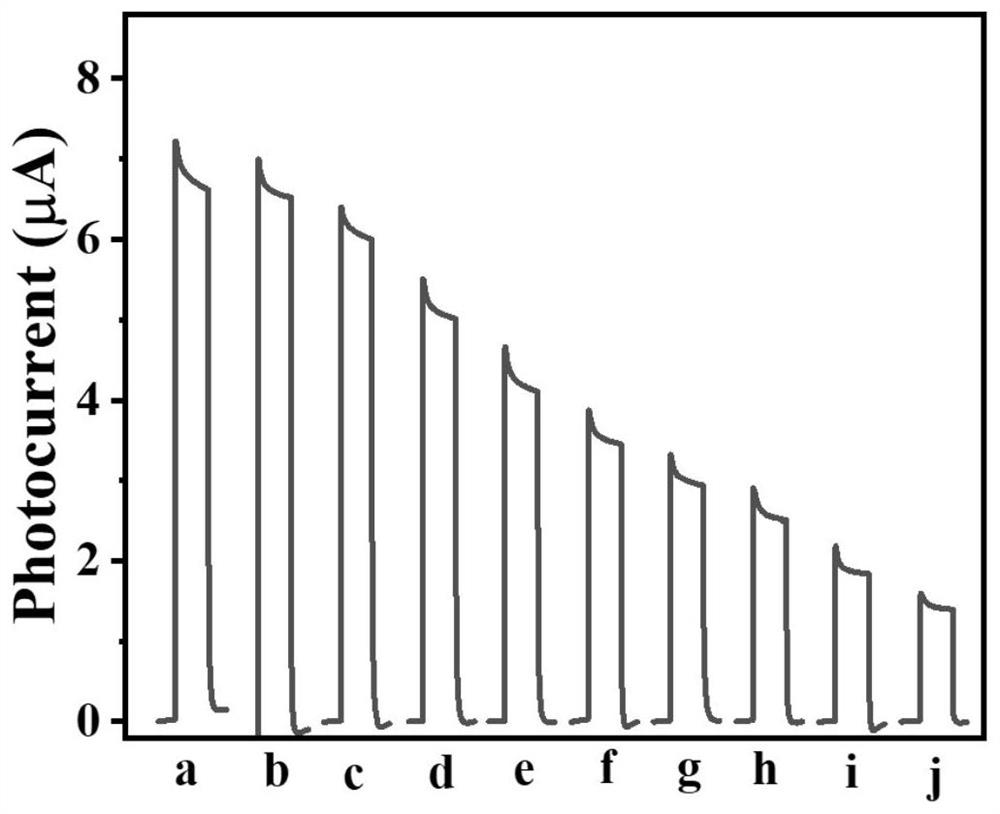

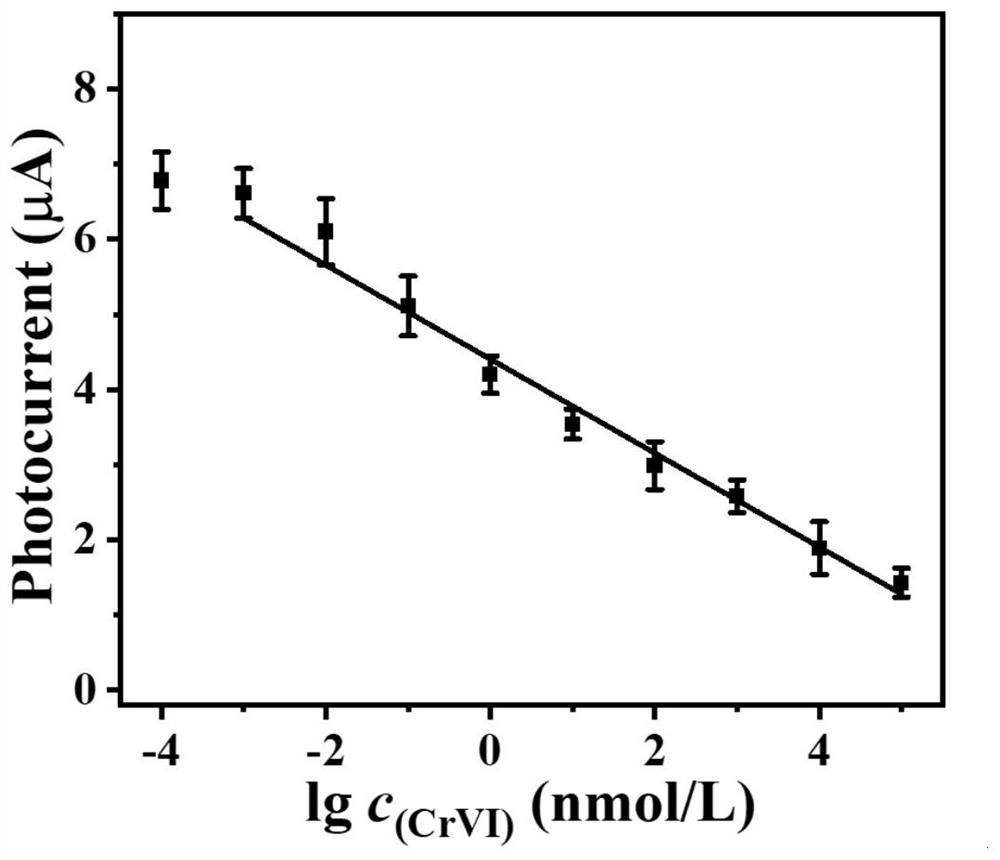

Method for detecting Cr (VI) in water body based on MXene/SnS2 functional composite material

PendingCN114674903ALarge specific surface areaGood biocompatibilityMaterial electrochemical variablesChemistryComposite material

The invention belongs to the field of functional materials and photoelectric sensing, a composite material obtained by combining a two-dimensional MXene material and SnS2 is used as a photosensitizer, and the photosensitizer is used for constructing a photoelectric sensor and detecting Cr (VI) in a water body. The MXene / SnS2 functional composite material is prepared by adopting a hydrothermal method, the photoelectrochemical sensor is constructed by utilizing the MXene / SnS2 functional composite material, and the photoelectrochemical sensor is a sensing device which takes a photosensitive material as a basis and converts an optical signal into an electric signal through a signal converter and outputs the electric signal. According to the composite material, attachment sites are provided for the visible-light-responsive SnS2 nanometer material based on MXene with the large specific surface area, the MXene and the SnS2 nanometer material are combined, the accumulation problem of MXene can be avoided, the electron transfer efficiency of the SnS2 material can be improved, the composite material is applied to the field of photoelectric sensors, the concentration of Cr (VI) in wastewater can be sensitively detected, and the application prospect is wide. The sensor also has the advantages of low cost, simple operation and high sensitivity.

Owner:JIANGSU UNIV

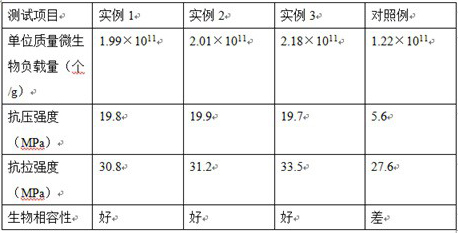

A kind of preparation method of microbial carrier

ActiveCN107267495BHigh porosityIncrease the areaOn/in inorganic carrierPhosphorus compoundsBiotechnologyEthylene diamine

The invention relates to the technical field of microbial immobilization, in particular to a preparation method for a microbial carrier. A porous cotton straw is used as a template, EDTA (Ethylene Diamine Tetraacetic Acid) is taken as a guiding agent to improve the purity of hydroxy calcium phosphate, a porous high-capacity hydroxy calcium phosphate carrier is prepared, mosses are loaded on the surface of the porous high-capacity hydroxy calcium phosphate carrier to provide places and nutrition for the growth of microorganisms, and good mechanical performance and excellent biocompatibility of the hydroxy calcium phosphate are used for finally preparing the microbial carrier with high biological capacity. The defects of poor mechanical performance, low biocompatibility and small biological capacity of a common microbial carrier are eliminated, and the microbial carrier with the high biological capacity has a wide application prospect.

Owner:上海同柏宸科生物技术有限公司

A biomimetic composite scaffold material doped with graphene and its construction method

InactiveCN108273139BGuaranteed water absorptionGuaranteed biocompatibilityTissue regenerationProsthesisSodium phosphatesFreeze-drying

The invention belongs to the field of tissue engineering scaffold materials, and provides a bionic composite scaffold material doped with graphene and an establishment method of the bionic composite support material. The establishment method comprises the following steps: firstly preparing a Cs acetic acid solution, a GP aqueous solution, a Gel aqueous solution and a graphene suspension, and thenmixing the Cs acetic acid solution and the GP aqueous solution to prepare a Cs / GP solution A; adding the Gel aqueous solution into the Cs / GP solution A to prepare a Cs / GP / Gel solution B; and adding the graphene suspension into the Cs / GP / Gel solution B to prepare a Cs / GP / Gel / Gr solution C, transferring the solution C into a low-temperature mold, freeze drying at a low temperature, and performing the subsequent treatment, thus obtaining the bionic cartilage composite support material. A mass ratio of chitosan Cs to beta-sodium glycerophosphate GP to gelatin Gel to graphene Gr in the bionic cartilage composite scaffold material is 1: (5 to 20): (1 to 5): (0.02 to 0.08). The bionic composite scaffold material has the advantages of simple process, easy control and low production cost; and a produced support product is uniform in porosity, has an inter-connective pore structure and has an excellent bionic effect.

Owner:DALIAN UNIV OF TECH

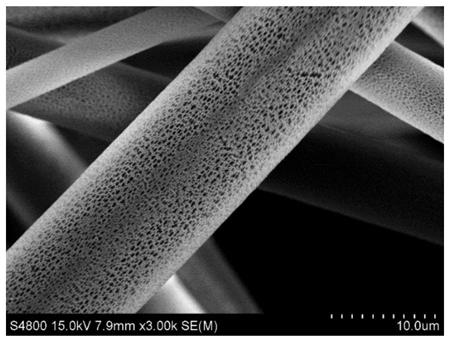

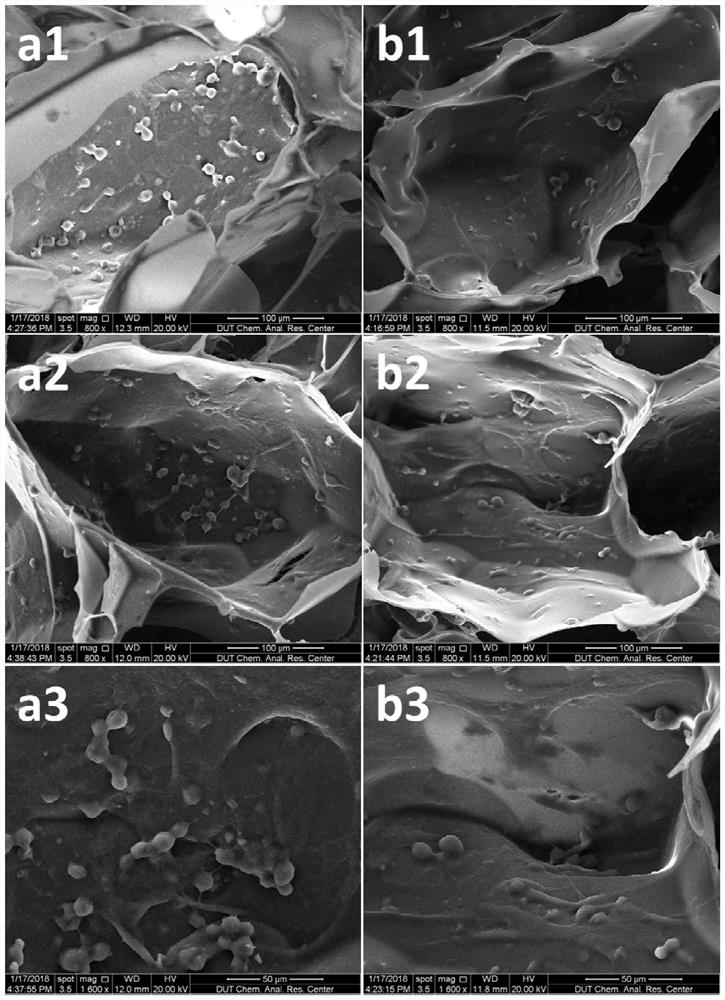

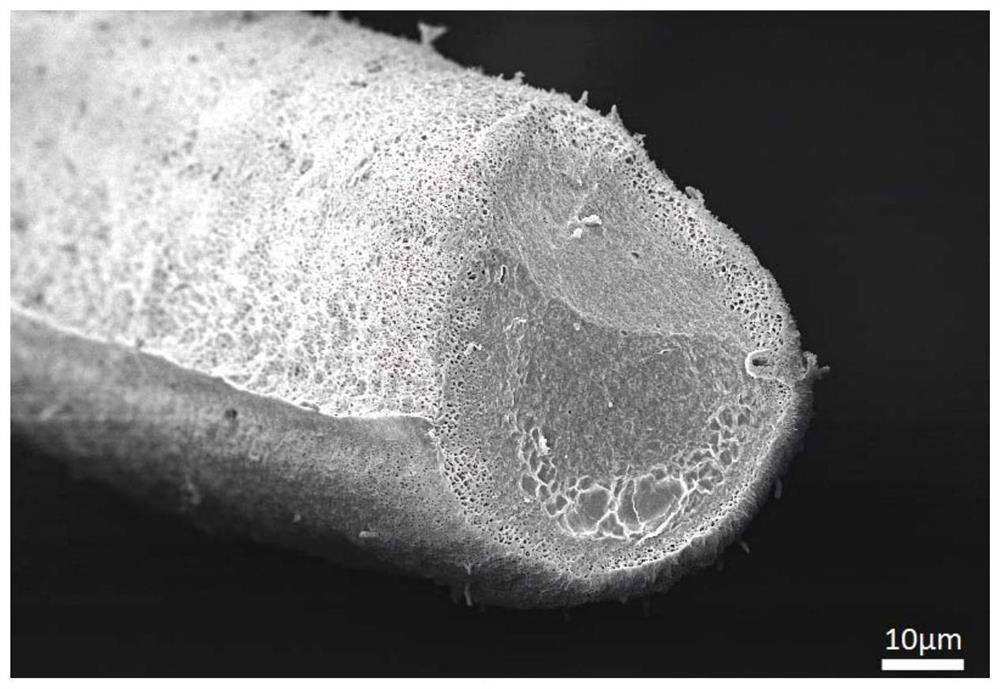

Sponge fiber, preparation method and application

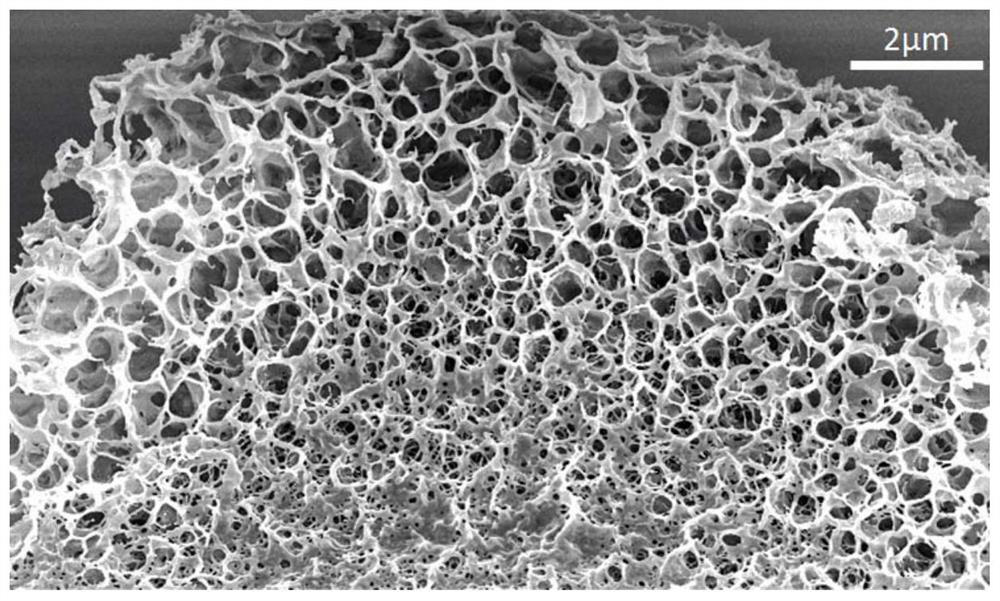

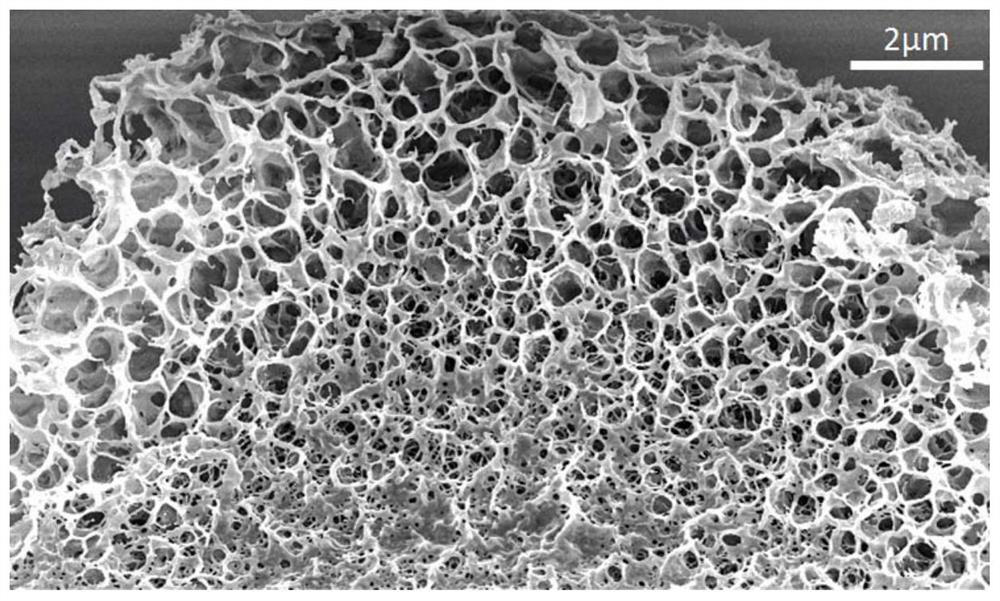

ActiveCN113122945AMultiple attachment sitesGood compatibilityMonocomponent cellulose artificial filamentCellulose/protein filament chemical after-treatmentFiberPolymer science

The invention discloses a sponge fiber, a preparation method and application, and belongs to the technical field of fibers. The sponge fiber is filamentous, the cross section of the sponge fiber is a net-shaped cross section, the net-shaped cross section comprises a central part and an edge part located on the periphery of the central part, and the average pore diameter of the central part is smaller than that of the edge part. The sponge fiber has a special structure, so that the sponge fiber has excellent performance in the fields of sound insulation materials and thermal insulation materials, and has wide application prospects in the fields of materials in direct contact with a human body and the technical field of biological scaffold materials.

Owner:WUYI UNIV

A kind of preparation method and application of graphene oxide

ActiveCN109704322BEnhanced bioaugmentationAvoid churnCarbon compoundsTreatment with anaerobic digestion processesTemperature controlFreeze-drying

The invention belongs to the technical field of sewage treatment, and relates to a preparation method and application of graphene oxide. First, graphite powder is added to a beaker containing concentrated sulfuric acid for pre-oxidation; then potassium permanganate is added to the beaker in an ice-water bath and stirred, After removing the ice-water bath, add deionized water at room temperature for stirring; then add saturated hydrogen peroxide solution slowly until the color of the mixture turns golden yellow and then stir; finally, wash the mixture, centrifuge, dialysis and freeze-drying in sequence. The brown-yellow flocculent graphene oxide is prepared. The whole preparation process does not require complicated temperature control, the operation is simple, and there is no high-temperature production stage, the production safety factor is improved, and the production cost is reduced. It has good strengthening performance for anammox bacteria, is suitable for industrial production, and has good economic and environmental benefits.

Owner:青岛绿洁坤环保科技有限公司

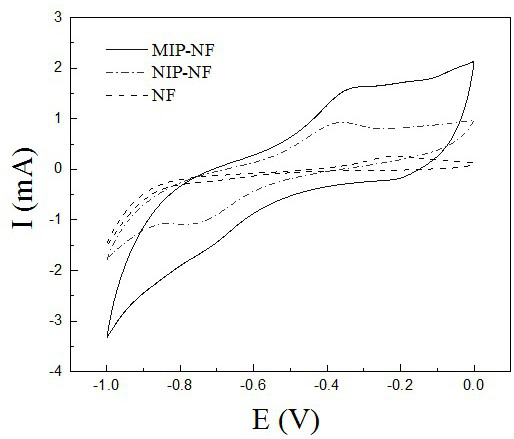

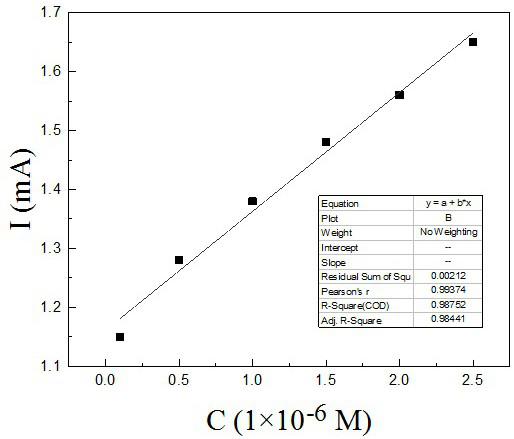

Molecularly imprinted electrochemical sensor for selective recognition of p-nitrophenol and its application

ActiveCN110487882BImprove conductivityGood water solubilityMaterial electrochemical variablesFunctional monomerNitrobenzene

The present invention relates to a molecularly imprinted electrochemical sensor for selective recognition of p-nitrophenol and its application. It uses nickel foam as a substrate, and the sulfuric acid solution of aniline and p-nitrophenol as an electrolyte. Surface polymerization to form molecularly imprinted polymers, the detection limit of p-nitrophenol is 1×10 ‑9 mol / L, the linear range is 2.5×10 ‑6 ~1×10 ‑7 mol / L, its specific preparation method comprises the following steps: one, the foamed nickel electrode that cuts is made into foamed nickel electrode; Two, functional monomer and template molecule are dissolved in acidic aqueous solution, mix uniformly, and functional monomer is aniline, The template molecule is p-nitrophenol; 3. The mixed solution in step 2 is used as an electrolyte solution, and then the nickel foam electrode is placed in the mixed solution, and electrochemically polymerized under the action of an electric field. The molecular imprint prepared by the invention has good water solubility and high sensitivity.

Owner:NORTHEAST GASOLINEEUM UNIV

Intercalation and layered ti using hydrazine hydrate 3 c 2 in situ synthesis of tio 2 @ti 3 c 2 method and product

ActiveCN109225290BIncrease layer spacingMultiple attachment sitesPhysical/chemical process catalystsArgon atmospherePhysical chemistry

Owner:ZHEJIANG UNIV

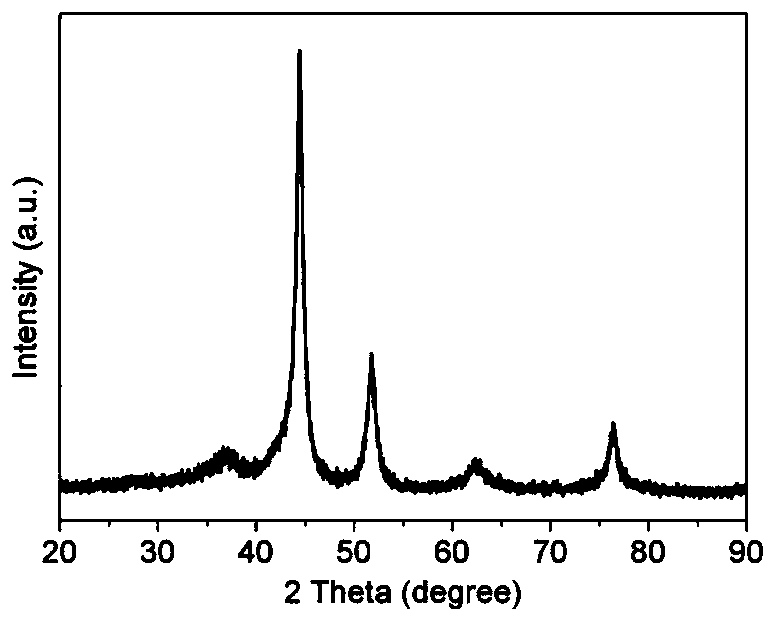

A kind of in-situ preparation method of ni/nio composite material and its application

ActiveCN109675568BHigh metal dispersionGood dispersionOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsHigh activityMaterials science

The invention belongs to the technical field of new materials and provides an in-situ preparation method and application of Ni / NiO composite materials. The preparation method includes the following steps: (1) fully dissolve the nickel source in the inorganic solvent to form solution A; (2) add a strong reducing agent to the solution A to form a mixed solution; (3) combine the solution obtained in step (2) The mixed liquid is subjected to a hydrothermal reaction to obtain a solid-liquid mixture, which is separated, washed, and dried to obtain the precursor I; (4) the precursor I in step (3) is subjected to a high-density thermal decomposition reaction to obtain Precursor II; (5) The precursor II in step (4) is subjected to a reduction reaction in a reducing gas atmosphere to obtain a Ni / NiO composite material. This method is easy to control the metal content, has high metal dispersion and strong interaction between the metal and the carrier, thereby increasing the number of active sites and promoting the transfer of electrons in the reaction, and obtaining Ni / NiO with higher activity and stability. composite materials.

Owner:NORTHEASTERN UNIV LIAONING

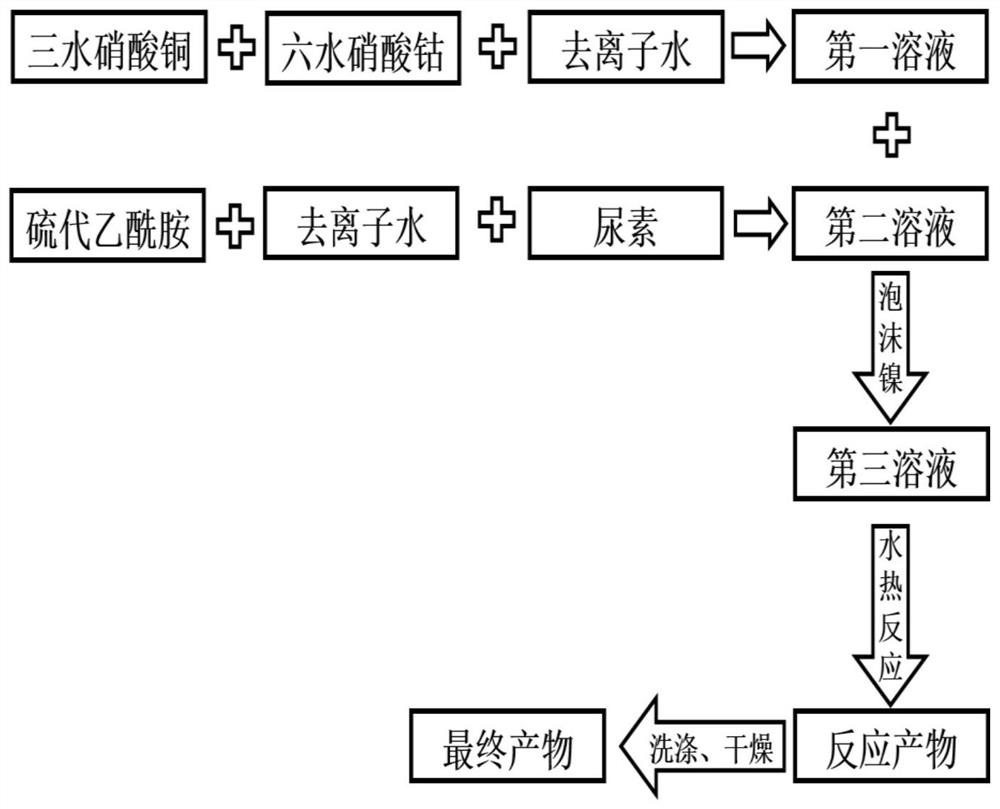

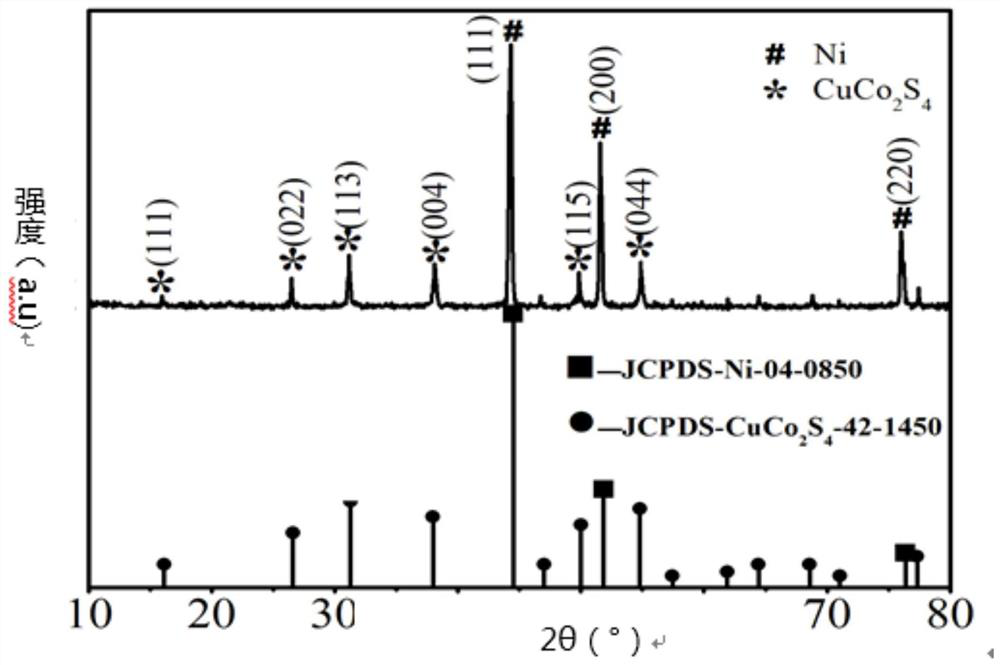

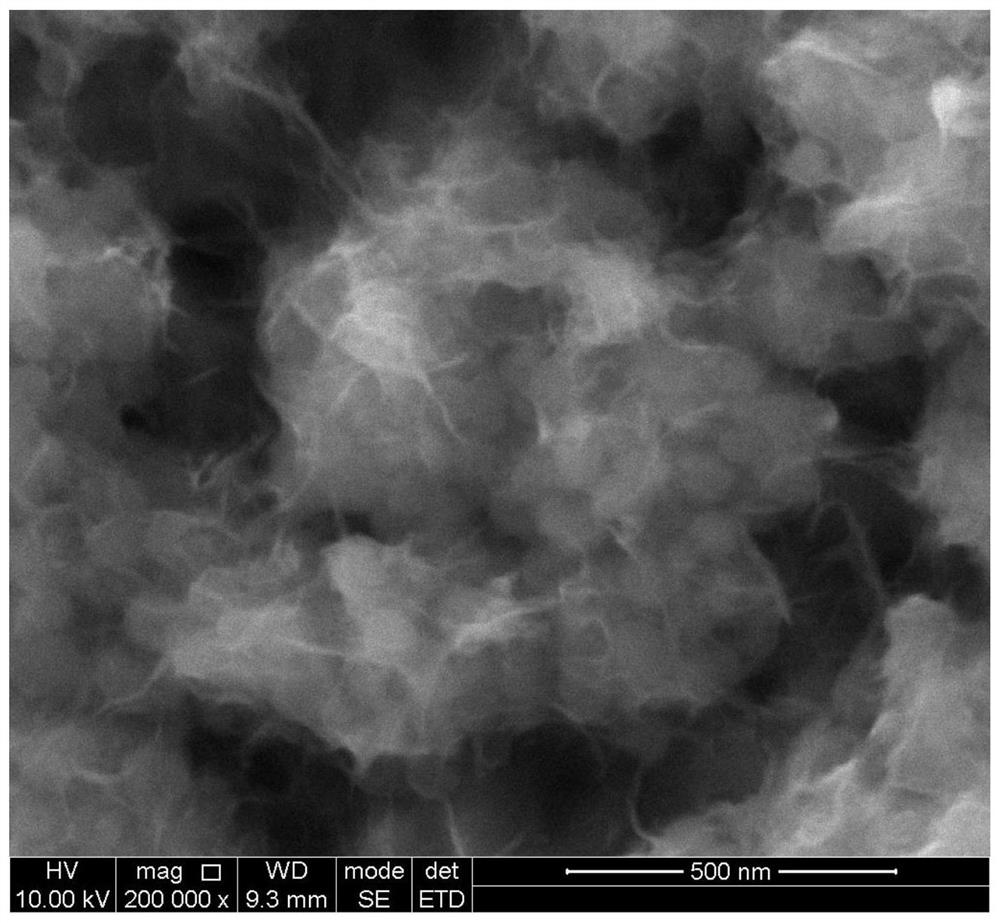

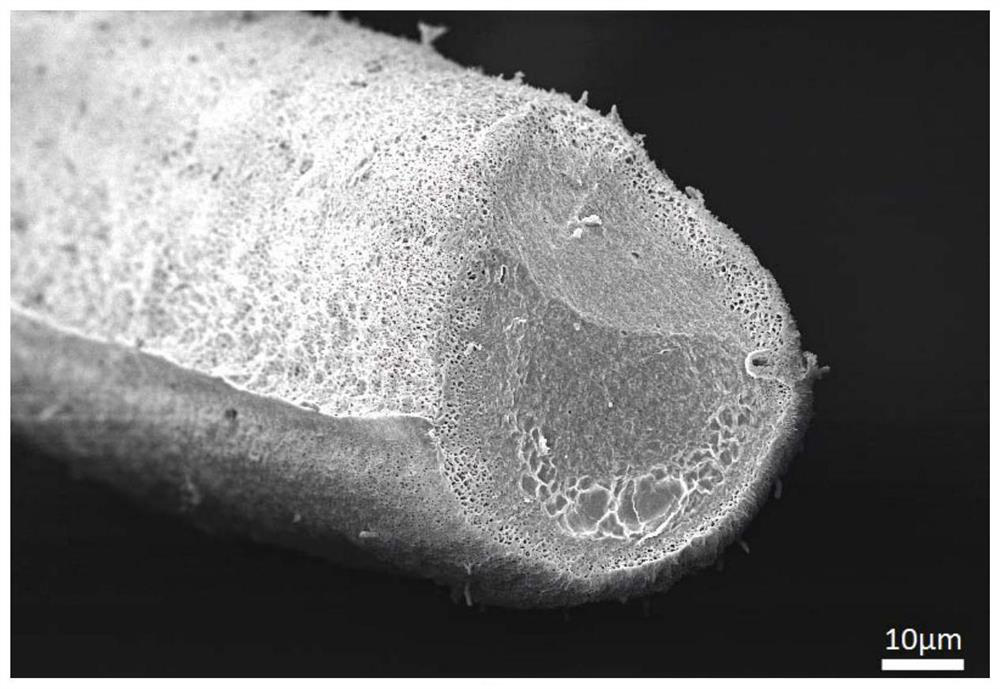

Self-supporting electrode material, preparation method and application thereof

ActiveCN109216708BImprove electrochemical performanceLower overpotentialMaterial nanotechnologyFuel and secondary cellsElectrical batteryNanoparticle

The invention relates to a self-supporting electrode material and its preparation method and application, belonging to the field of electrode materials. The self-supporting electrode material prepared by the present invention is composed of nanoparticles with a diameter of about 30-60nm gathered together, and coated with a layer of nano-film on the outside to form a nano-spherical structure. The electrode material prepared by the present invention has excellent electrochemical performance, exhibits good electrocatalytic performance in the battery, and also avoids side reactions and poor cycle performance of the lithium-oxygen battery due to the use of carbon materials and binders in the charging process. question.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

A kind of sponge fiber, preparation method and application

ActiveCN113122945BMultiple attachment sitesGood compatibilityMonocomponent cellulose artificial filamentCellulose/protein filament chemical after-treatmentFiberThermal insulation

The invention discloses a sponge fiber, a preparation method and an application, and belongs to the field of fiber technology. A sponge fiber is filamentous and its cross-section is a net-like cross-section. The net-like cross-section includes a central part and an edge part located on the periphery of the central part. The average pore diameter of the central part is smaller than that of the edge part. The sponge fiber provided by the invention has a special structure, so it performs well in the fields of sound-insulating materials and heat-retaining materials, and has broad application prospects in the fields of materials that directly contact with the human body and in the technical field of biological scaffold materials.

Owner:WUYI UNIV

High-strength wear-resistant closed steel frame and machining process thereof

ActiveCN113215566AImprove wear resistanceReduce porosityLiquid/solution decomposition chemical coatingCleaning processes and apparatusPipe fittingSurface oxidation

The invention discloses a high-strength wear-resistant closed steel frame and the a machining process thereof. The process includes the steps that during preparation, firstly, an alloy steel pipe fitting is subjected to surface laser cleaning, and a surface oxidation film of the alloy steel pipe fitting is removed by conducting laser cleaning on the surface of the alloy steel pipe fitting, so that the surface wettability of the alloy steel pipe fitting can be improved; in a subsequent laser cladding procedure, cladding liquid can be fully spread out, so that a subsequently-formed wear-resistant layer is more uniform and compact, has few pores and is more excellent in wear resistance; and meanwhile, a rough structure can be formed on the surface of alloy steel after laser cleaning, so that the surface roughness can be improved, the adhesive force of a thick laser cladding layer is further improved, and the comprehensive wear resistance of the alloy steel is improved. The machining process of the high-strength wear-resistant closed steel frame is reasonable in design and easy to operate, the wear-resisting layer is formed on the surface of the prepared alloy steel pipe fitting, a steel frame is obtained through splicing installation, the wear-resisting layer can effectively improve the wear-resisting performance and the comprehensive mechanical performance of the alloy steel frame, and the alloy steel frame can be suitable for multiple technical fields and has high practicability.

Owner:常州市天河电器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com