Self-supporting electrode material, preparation method and application thereof

A self-supporting electrode, copper nitrate technology, applied in nanotechnology for materials and surface science, battery electrodes, fuel cell half-cells and secondary battery-type half-cells, etc., can solve unsafe, organic solvents Not environmentally friendly, easy to explode and other problems, to achieve the effect of easy operation, avoid toxicity, and low overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

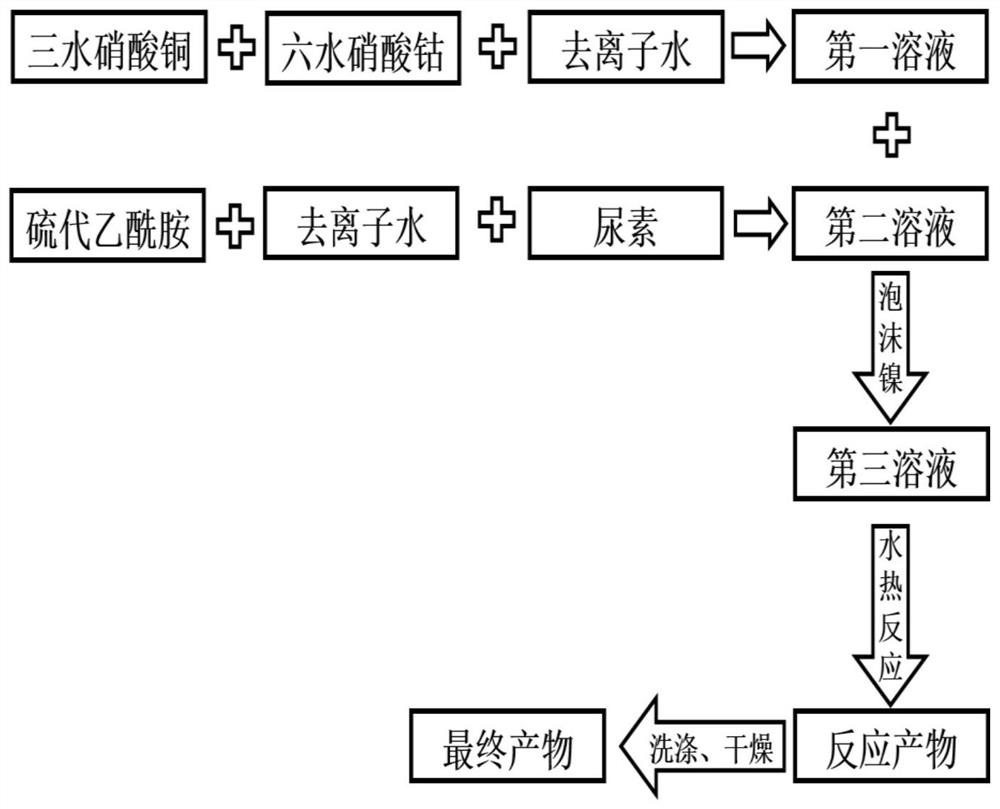

[0043] The preparation method of self-supporting electrode material is prepared according to the following steps:

[0044] a, copper nitrate and cobalt nitrate are dissolved in water to obtain the first solution;

[0045] b, dissolving thioacetamide in water, and then adding urea to obtain a second solution;

[0046] c. Mix the first solution and the second solution, then add nickel foam, and react at 180°C for 24 hours;

[0047] d. Washing and drying the reacted product in sequence to obtain a self-supporting electrode material.

[0048] The present invention needs to strictly control the two parameters of temperature and time, and only under the limited temperature and time of the present invention, the formation of the target product can be guaranteed. Too high or too low reaction temperature, too long or too short reaction time are not conducive to the formation of the target product, and will also affect the composition and morphology of the target product.

[0049] In...

Embodiment 1

[0059] The preparation of embodiment 1 self-supporting electrode material

[0060] a, according to the molar ratio of copper nitrate, cobalt nitrate, thioacetamide and urea is 1:2:4.35:2.1, take copper nitrate trihydrate 0.23g, cobalt nitrate hexahydrate 0.56g, thioacetamide 0.31g, urea 0.12g;

[0061] b. Dissolve 0.23g copper nitrate trihydrate and 0.56g cobalt nitrate hexahydrate in 20g water to obtain the first solution; dissolve 0.31g thioacetamide in 15mL deionized water, then add 0.12g urea to obtain the second solution solution;

[0062] c. Pour the first solution into the second solution, add a piece of nickel foam for stirring, and then carry out hydrothermal reaction; the reaction temperature of the hydrothermal reaction is controlled at 180 degrees Celsius, and the reaction time is controlled at 24 hours.

[0063] d. Washing and drying the product after the hydrothermal reaction in sequence to obtain the electrode material S1.

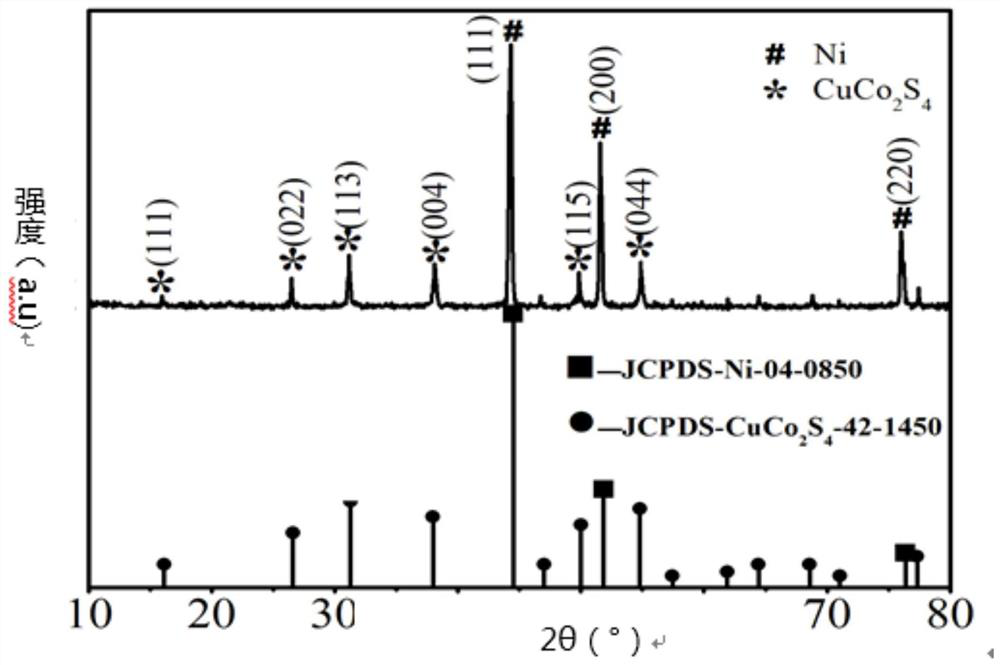

[0064] The XRD pattern of S1 is as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com