Method and product of in-situ synthetic TiO2@Ti3C2 by using isopropylamine intercalated and layered Ti3C2

A technology of in-situ synthesis and isopropylamine, which is applied in the field of Ti3C2 preparation, can solve the problems of small band gap, reduced electron-hole recombination, and poor catalytic performance, so as to increase interlayer spacing, improve purity and crystallinity, and benefit The effect of catalytic degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1) 15g Ti 3 AlC 2 -MAX phase ceramic powder was slowly added to 300mL of HF solution with a mass concentration of 49%, and reacted for 36h in a magnetic stirrer at 50°C in an oil bath;

[0049] 2) After the reaction, centrifuge the resulting solution at 3000 rpm for 5 minutes, pour out the supernatant, and wash the precipitate with deionized water, shake and shake well, then centrifuge under the same conditions, and repeat 6 times. The pH of the final supernatant was measured to be between 5 and 6, and then the precipitate was washed with absolute ethanol, centrifuged after shaking, and repeated twice with the same speed and time of centrifugation. After centrifugation, the resulting solution was suction filtered to obtain a precipitate. The resulting precipitate was vacuum dried at 60°C for 24h to obtain Mxene-Ti 3 C 2 material;

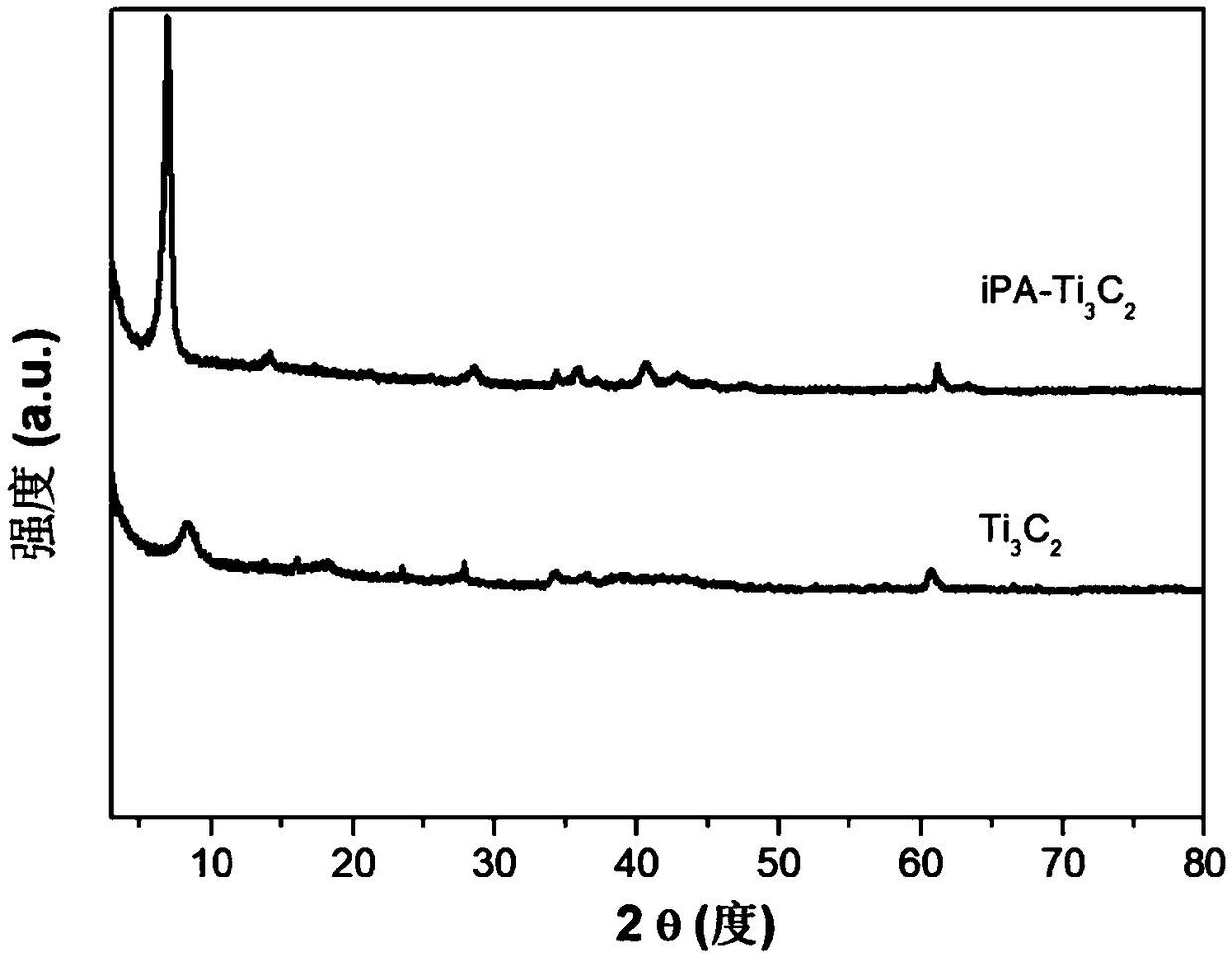

[0050] 3) The Mxene-Ti obtained in step 2) 3 C 2 The materials, isopropylamine and deionized water are mixed according to the feed ratio of 1g:20...

Embodiment 2

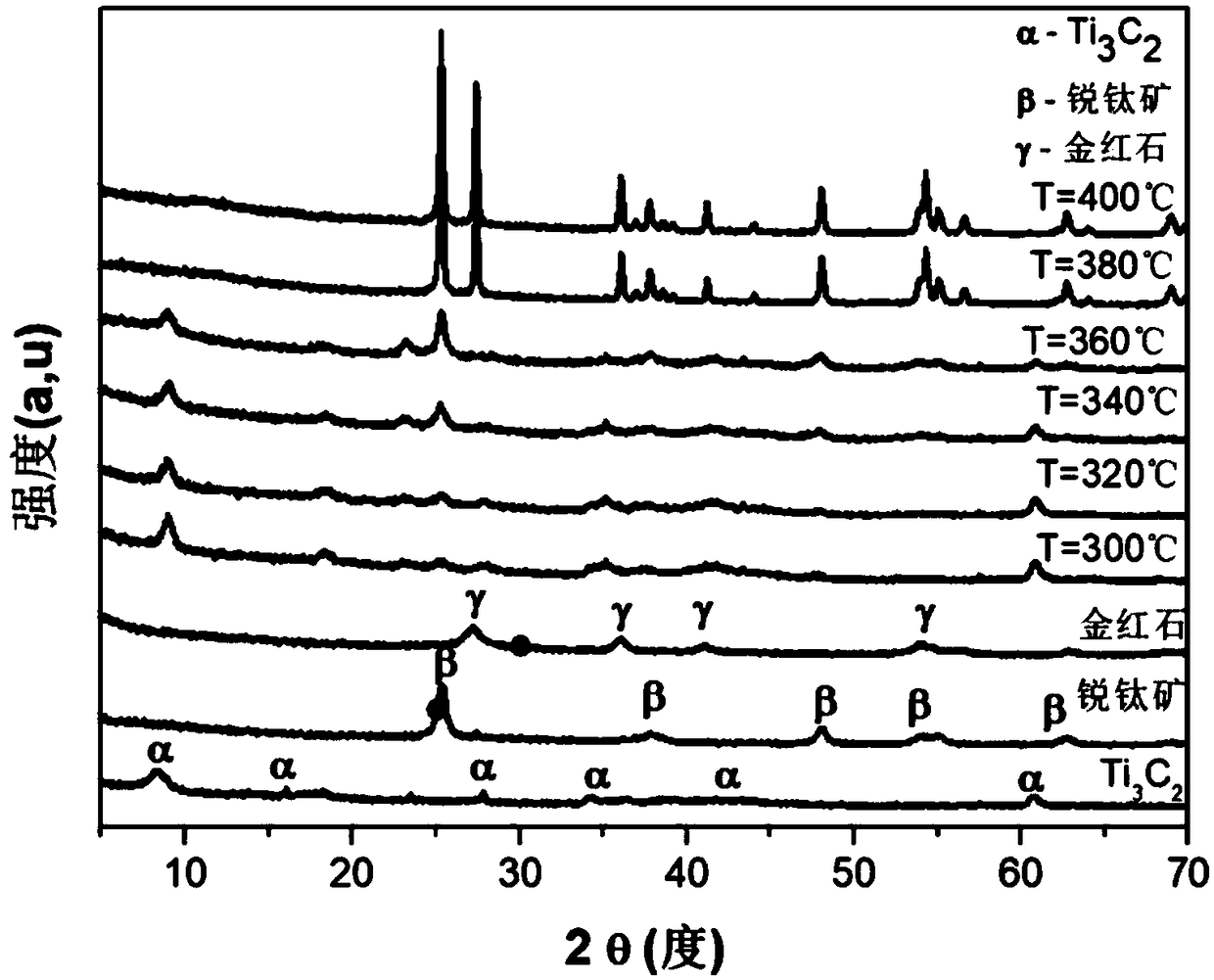

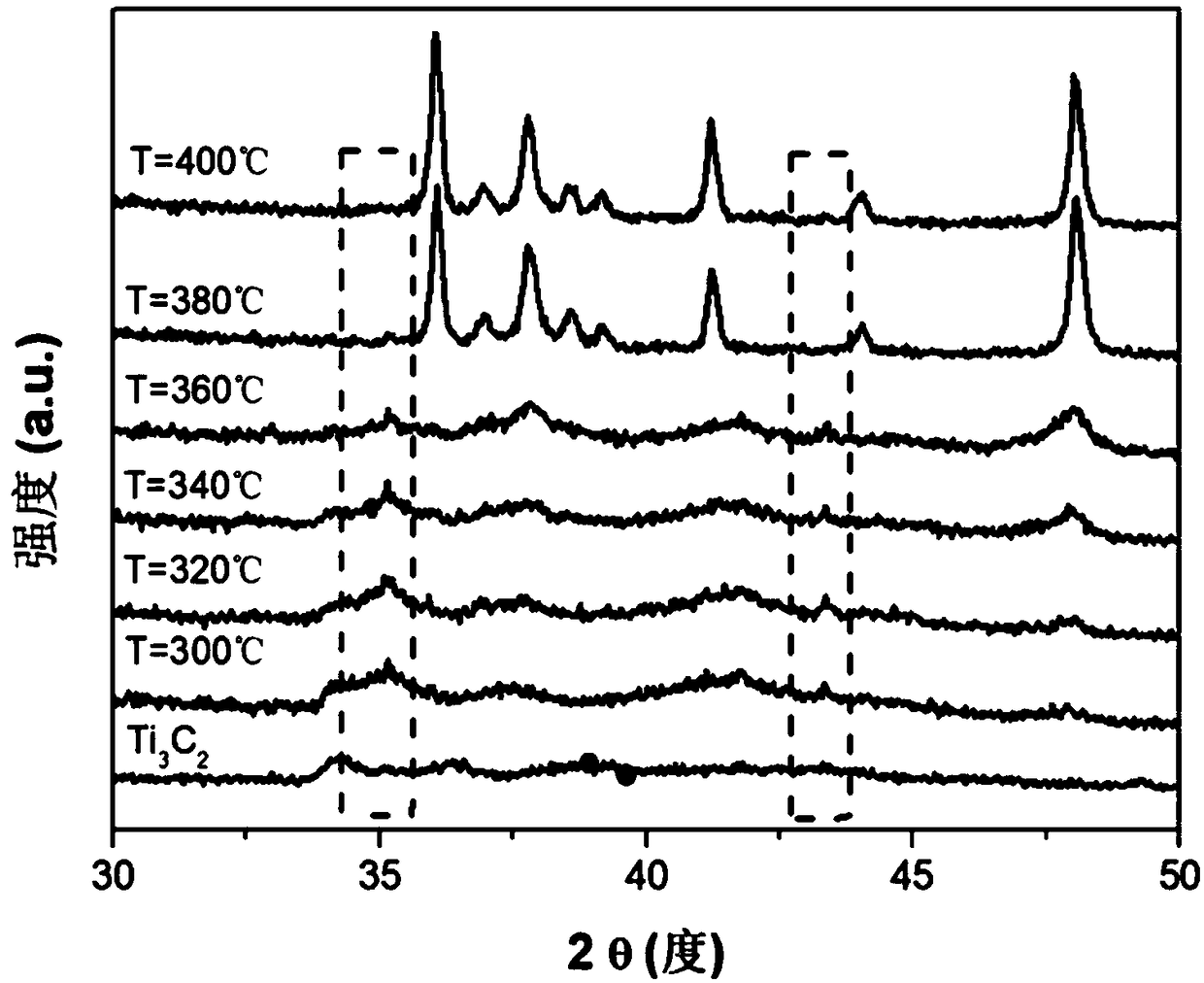

[0054] The preparation process refers to the process in Example 1. The difference is that the final temperature maintained in step 5) is 320°C for 1 hour. After the procedure is over, natural cooling is used. When the temperature drops to room temperature, the sample is taken out to obtain TiO 2 @Ti 3 C 2 material.

Embodiment 3

[0056] The preparation process refers to the process in Example 1. The difference is that the final temperature maintained in step 5) is 340°C for 1 hour. After the program ends, natural cooling is used. When the temperature drops to room temperature, the sample is taken out to obtain TiO 2 @Ti 3 C 2 material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com