Suspension bed hydrogenation catalyst and preparation method and application thereof

A hydrogenation catalyst and catalyst technology, which are applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of high catalyst cost, complicated preparation method and increased solid content of materials and other problems to achieve the effect of shortening the time of oxidation treatment, improving catalytic efficiency, and improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

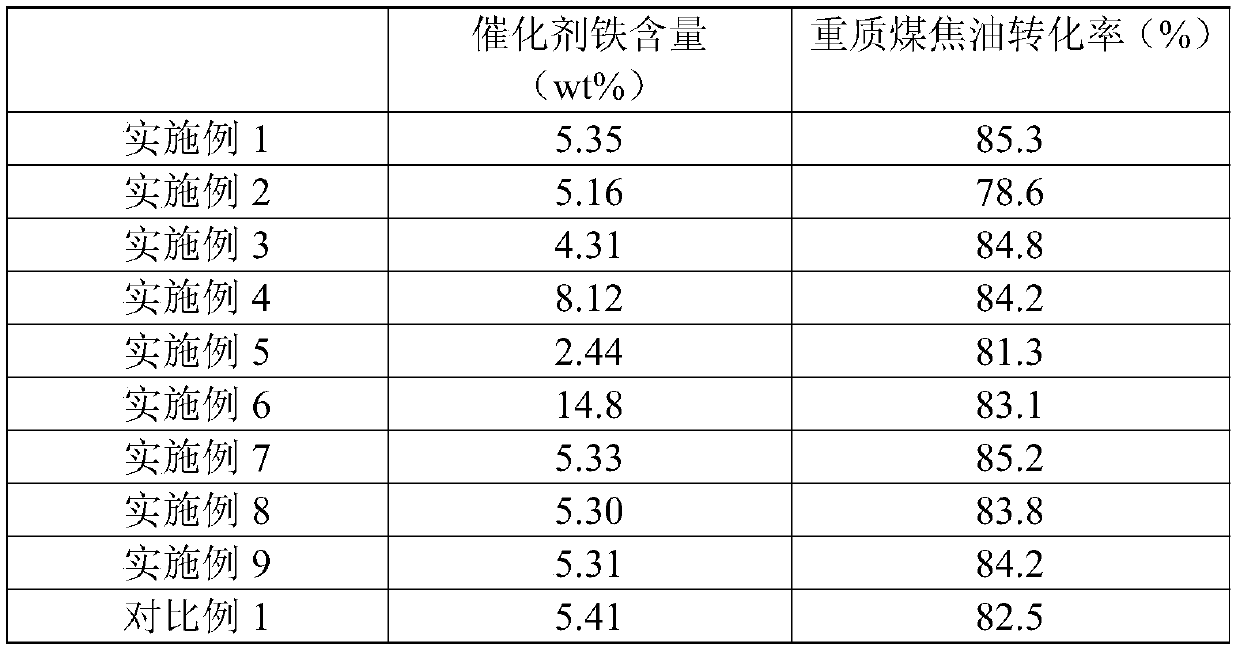

Examples

Embodiment 1

[0054] Catalyst preparation:

[0055] (1) 100g pyrolysis coke powder and 200g water are mixed into slurry;

[0056] (2) add 270g FeSO in the slurry that step (2) obtains 4 Aqueous solution, stirring; where FeSO 4 The concentration of the aqueous solution is 10wt%;

[0057] (3) dripping concentration in the product of step (2) is the sodium hydroxide solution of 10wt% to the reaction system pH value is 8, and the process keeps stirring;

[0058] (4) Add 30mL concentration of 25wt% hydrogen peroxide solution to the product of step (3), and dropwise add 10wt% sodium hydroxide solution to maintain the pH of the system at 8.5, oxidize for 5min, filter, and dry to obtain the catalyst.

Embodiment 2

[0060] In this embodiment, the pyrolysis coke powder in Embodiment 1 is replaced by coal powder, and other conditions are completely the same as those in Embodiment 1.

Embodiment 3

[0062] In this embodiment, the FeSO in embodiment 1 4 The add-on of aqueous solution is replaced as 176g, and the add-on of control hydrogen peroxide solution makes wherein the molar weight of hydrogen peroxide and FeSO 4 The ratio of the molar amount is the same as that of Example 1, and other conditions are completely the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com