Preparation method and application of honeycomb ceramic/biochar film/rare earth perovskite monolithic catalyst

A monolithic catalyst and honeycomb ceramic technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., to promote adsorption, inhibit aggregation, and inhibit grain growth big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The pomegranate peel is washed, dried, and ground to obtain the pomegranate peel powder. Weigh 4.33g of lanthanum nitrate and 4.04g of ferric nitrate and dissolve them in 100mL of deionized water, add 1.0g of pomegranate peel powder, stir in a water bath at 80°C, keep warm for 3h, add ammonia water dropwise to adjust the pH value to neutral, and impregnate the honeycomb ceramics in the obtained suspension. Put it in the turbid liquid for 2 hours, dry it after purging, put it in a muffle furnace at 400°C for 2 hours, and get the finished honeycomb ceramic / biological carbon film / LaFeO 3 .

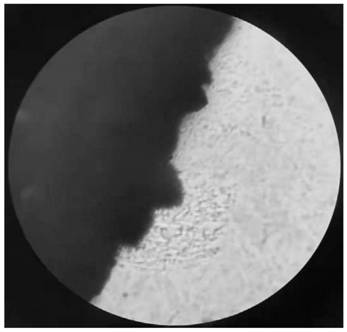

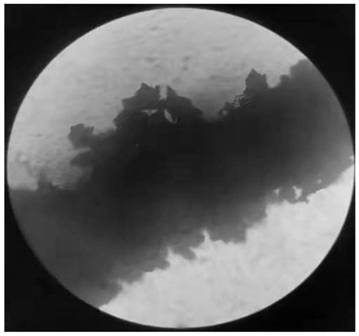

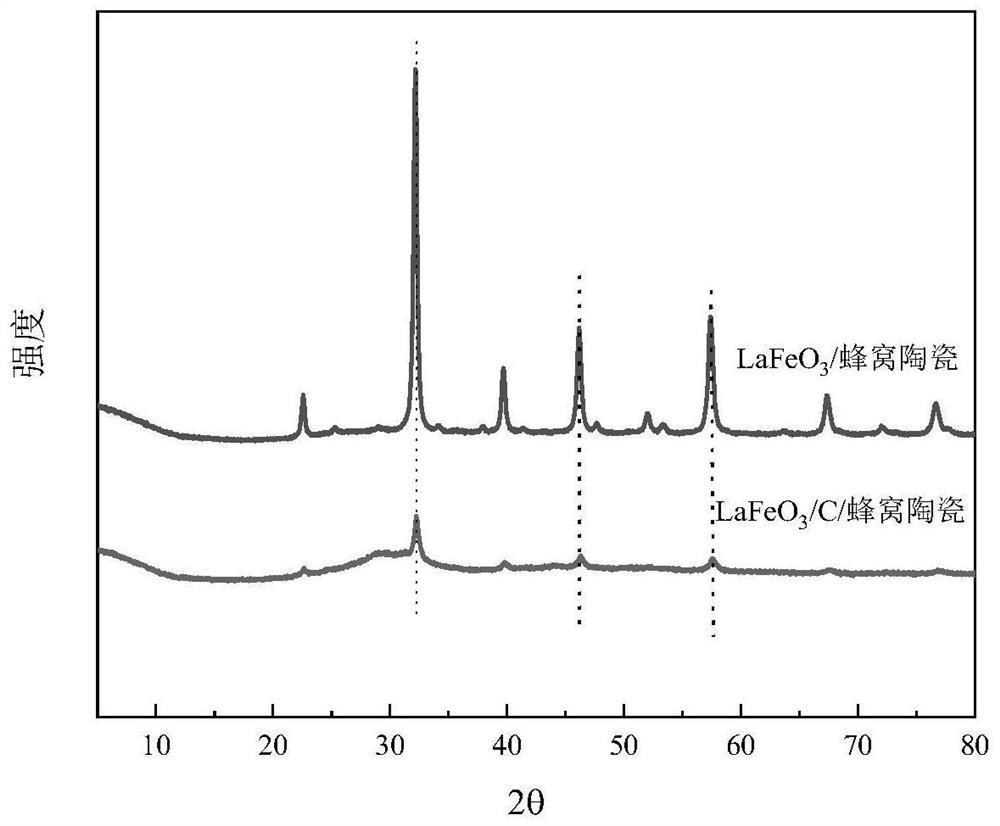

[0033] Without affecting the overall structure of the honeycomb ceramics, scrape off the powder from the surface of the honeycomb ceramics, and perform an X-ray powder diffraction experiment on the sample, and at the same time observe the morphology and structure of the coated honeycomb ceramics under a microscope, according to the example The LaFeO prepared by the process parameters ...

Embodiment 2

[0039] The pomegranate peel is washed, dried, and ground to obtain the pomegranate peel powder. Weigh 4.33g of lanthanum nitrate and 2.91g of cobalt nitrate and dissolve them in 100mL of deionized water, add 1.5g of pomegranate peel powder, stir in a water bath at 60°C, keep warm for 4h, add ammonia water dropwise to adjust the pH value to neutral, and impregnate the honeycomb ceramics in the obtained suspension. Put it in the turbid liquid for 2 hours, dry it after purging, put it in a muffle furnace at 400°C for 3 hours, and get the finished honeycomb ceramic / biological carbon film / LaCoO 3 .

[0040] Test LaCoO through embodiment 1 method 3 / Biological carbon film / Honeycomb ceramic composite T 90 It is 309°C.

Embodiment 3

[0042] The pomegranate peel is washed, dried, and ground to obtain the pomegranate peel powder. Weigh 4.33g of lanthanum nitrate and 2.50g of manganese nitrate and dissolve them in 100mL of deionized water, add 2g of pomegranate peel powder, stir in a water bath at 90°C, keep warm for 4 hours, add ammonia water dropwise to adjust the pH value to neutral, and impregnate the honeycomb ceramics in the obtained suspension solution for 4 hours, purged and then dried, then placed in a muffle furnace at 400°C for 4 hours to obtain the finished honeycomb ceramic / biological carbon film / LaMnO 3 .

[0043] Test LaMnO through embodiment 1 method 3 / Biological carbon film / Honeycomb ceramic composite T 90 It is 302°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com