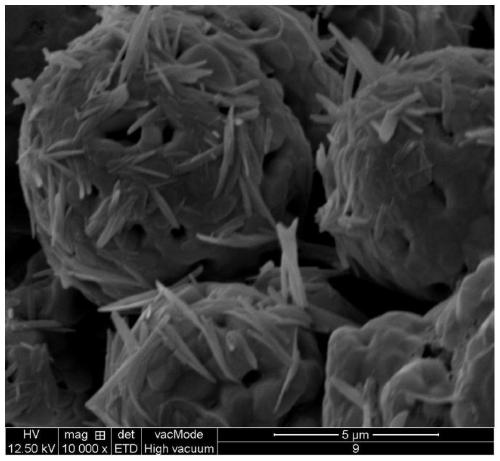

Micron hollow porous composite spherical sodium ion battery cathode material and preparation method thereof

A sodium-ion battery, hollow porous technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve problems such as insufficient rate performance and insufficient structural stability, and achieve shortening of the de-intercalation path, prevention of agglomeration, and rate of good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

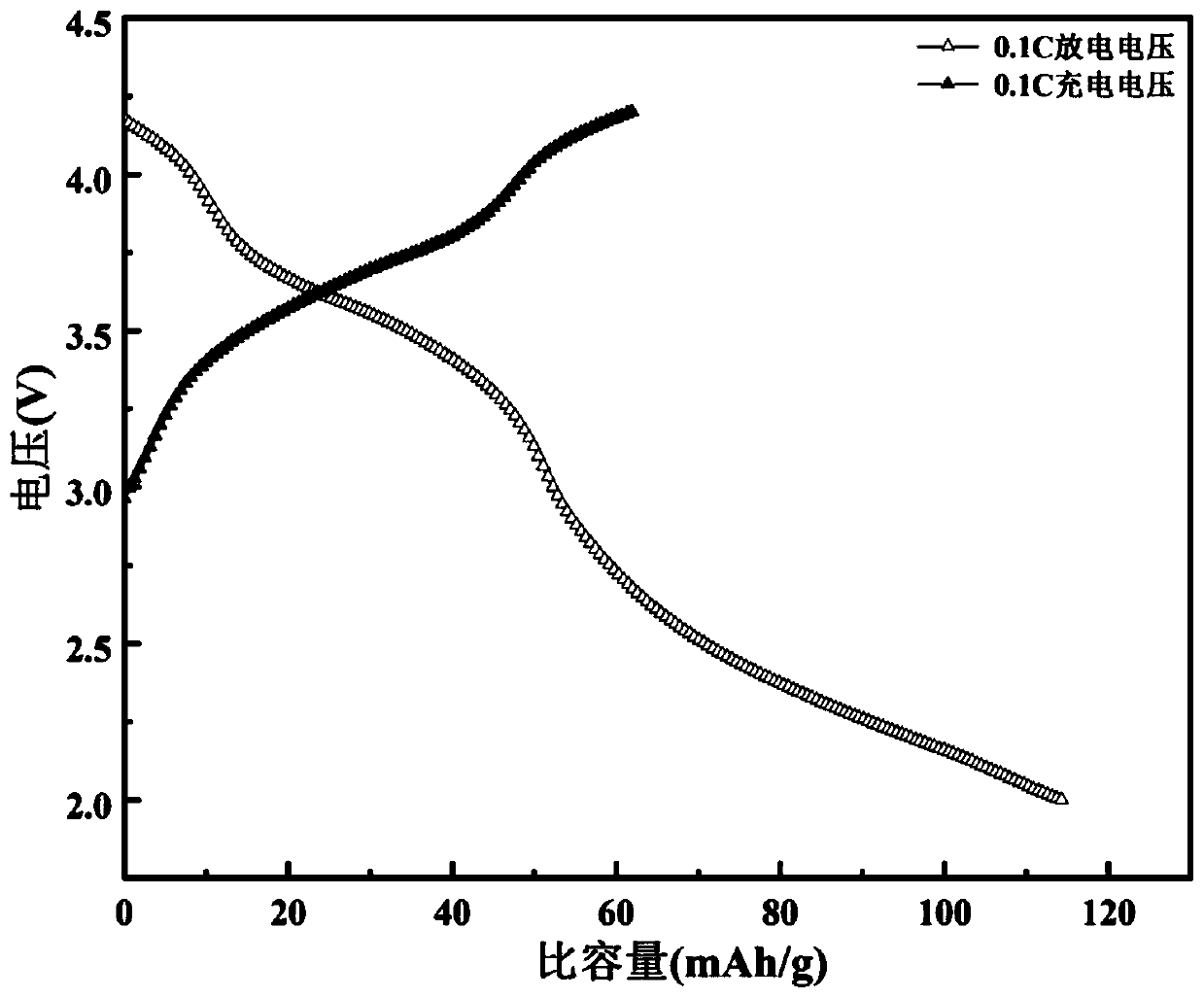

Embodiment 1

[0052] (1) Weigh 5mol of nickel sulfate hexahydrate, 5mol of cobalt sulfate heptahydrate, and 20mol of manganese sulfate monohydrate, dissolve them in 20L of deionized water to form a 1.5mol / L mixed solution, and then prepare 1.5mol / L of carbonic acid Sodium solution, the ratio of the molar weight of nickel salt, cobalt salt, manganese salt to the molar weight of sodium carbonate is 1:1; with the 50L reactor as the reactor, the 20L mixed solution and the 20L sodium carbonate solution are separated by 2L through a peristaltic pump The speed of / h is added to the reaction kettle, and the co-precipitation reaction is carried out by stirring at a speed of 200r / min under the condition of 50°C; at the same time, the pH value of the reaction solution is adjusted to 8.0 by adding 12wt% ammonium bicarbonate, and then reacted for 6 hours. Adjust the pH value to 8.5 and react for 4 hours. After the obtained precipitate is washed, filtered and dried, nickel-cobalt-manganese carbonate is ob...

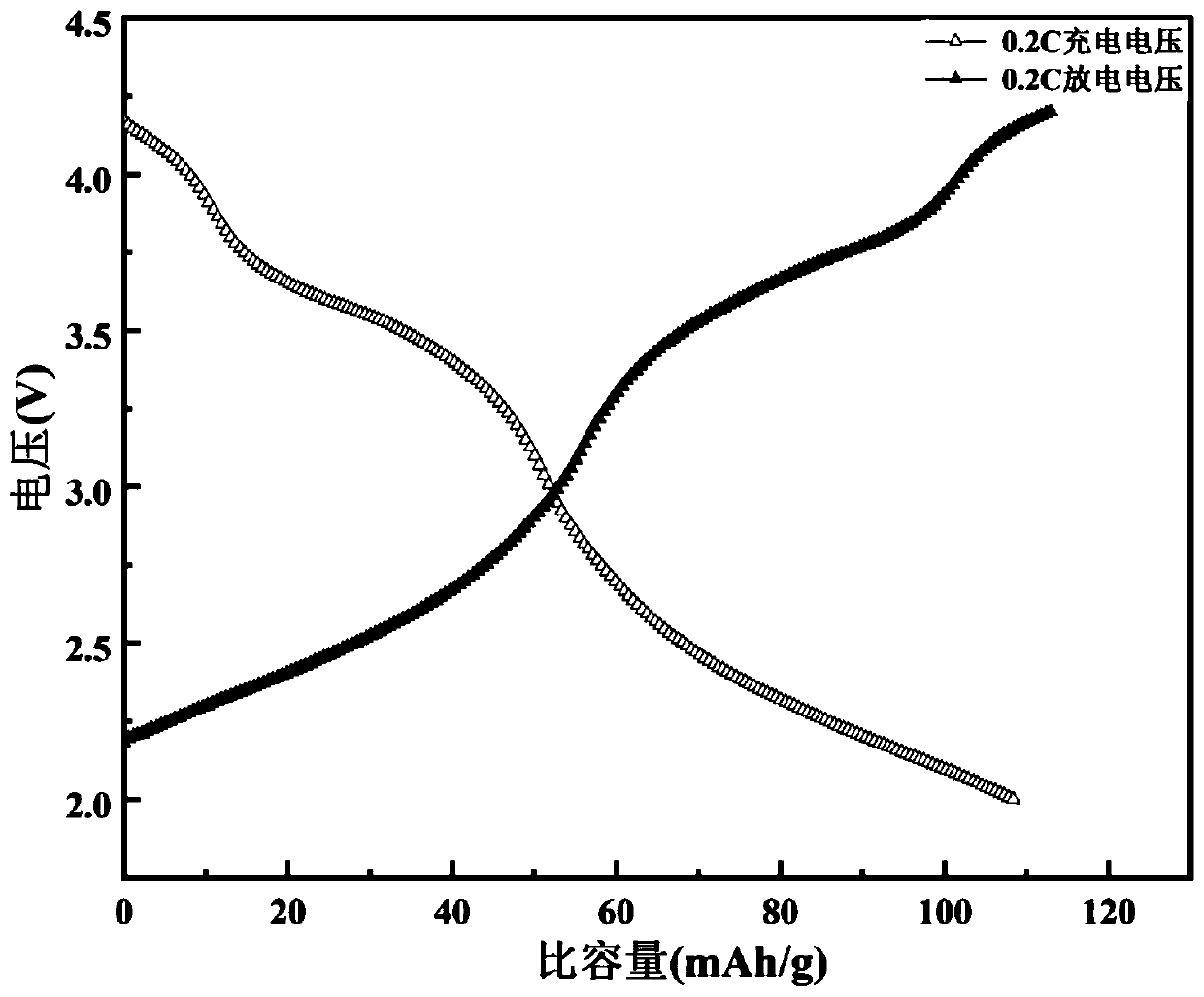

Embodiment 2

[0059] (1) Weigh 1.5mol nickel acetate tetrahydrate, 1.5mol cobalt acetate tetrahydrate, and 12mol manganese acetate tetrahydrate, dissolve them in 10L deionized water to form a 1.5mol / L mixed solution, and then prepare lye, alkali The liquid contains 1.5 mol / L sodium hydroxide and 0.003 mol / L ammonia water at the same time, the ratio of the sum of the molar weight of nickel salt, cobalt salt and manganese salt to the molar weight of lye solute is 1:2; a 50L reactor is used as the reactor , 10L mixed solution and 20L lye solution were added to the reaction kettle at a speed of 1L / h and 2L / h through a peristaltic pump, and the co-precipitation reaction was carried out at a speed of 250r / min under the condition of 55°C; by adding 12wt% ammonia water adjusts the pH value of the reaction solution to 7.5 and reacts for 4 hours, then adjusts the pH value to 9 and reacts for 6 hours, and the obtained precipitate is washed, filtered and dried to obtain the hydroxide of nickel-cobalt-ma...

Embodiment 3

[0066] (1) Weigh 5mol of nickel oxalate dihydrate, 5mol of cobalt oxalate dihydrate, and 20mol of manganese chloride tetrahydrate, and dissolve them in 20L of deionized water to form a mixed solution of 1.5mol / L; then prepare lye, alkali The liquid contains 2mol / L sodium carbonate and 0.002mol / L ammonia water at the same time, the ratio of the sum of the molar weight of nickel salt, cobalt salt and manganese salt to the molar weight of lye solute is 1:1.5; with the 50L reactor as the reactor, pass The peristaltic pump adds 20L mixed solution and 22.5L lye into the reaction kettle at a speed of 2L / h and 2.25L / h respectively, and stirs at a speed of 240r / min under the condition of 52°C for coprecipitation reaction; by adding 12wt % ammonia water to adjust the pH value of the reaction solution to 7.5 and react for 4 hours, then adjust the pH value to 8.5 and react for 6 hours, and the resulting precipitate is filtered and dried to obtain nickel-cobalt-manganese carbonate; the dryi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com