Hydrophobic sponge loaded with carbon nanotubes, preparation method and application of hydrophobic sponge in oil-water separation

A carbon nanotube and hydrophobic sponge technology is applied in the field of carbon nanotube-loaded hydrophobic sponge and its preparation, and can solve the problems of low oil absorption efficiency and oil-water separation efficiency, unsatisfactory hydrophobic oil absorption effect, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention provides a method for preparing a supported carbon nanotubes hydrophobic sponge, comprising the steps of:

[0027] The urethane sponge immersed H 2 O 2 / H 2 SO 4 The oxidation reaction mixture solution to obtain a hydroxyl group-rich urethane sponge;

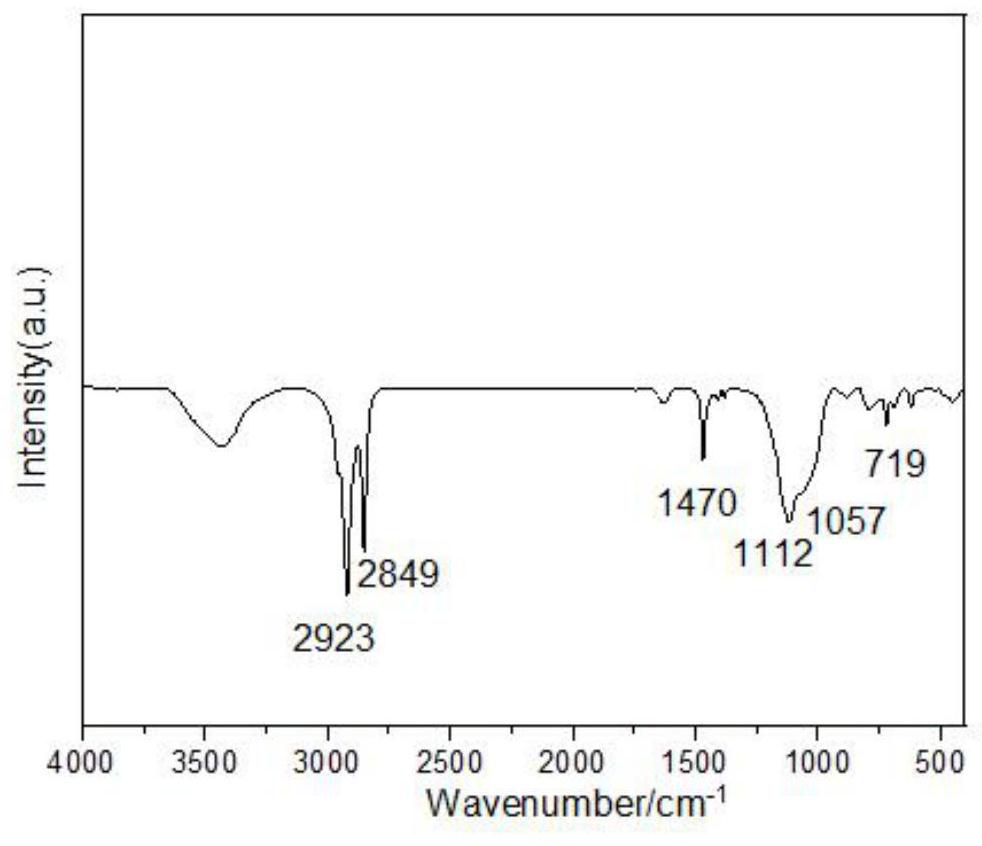

[0028] The coupling agent, hydroxylated benzene mixing carbon nanotubes and a solvent, to obtain a modified solution; the silane coupling agent is a silane coupling agent is C16 ~ C26;

[0029] The hydroxyl group-rich polyurethane sponge is immersed in the modified liquid to perform a diolation modification to obtain a hydrophobic sponge for load carbon nanotubes.

[0030] In the present invention, without special instructions, the raw materials are known in the art using commercially available.

[0031] The present invention is a polyurethane sponge impregnated into H 2 O 2 / H 2 SO 4 The oxidation reaction mixture solution to obtain a hydroxyl group-rich urethane sponge.

[0032] Prior to said oxidati...

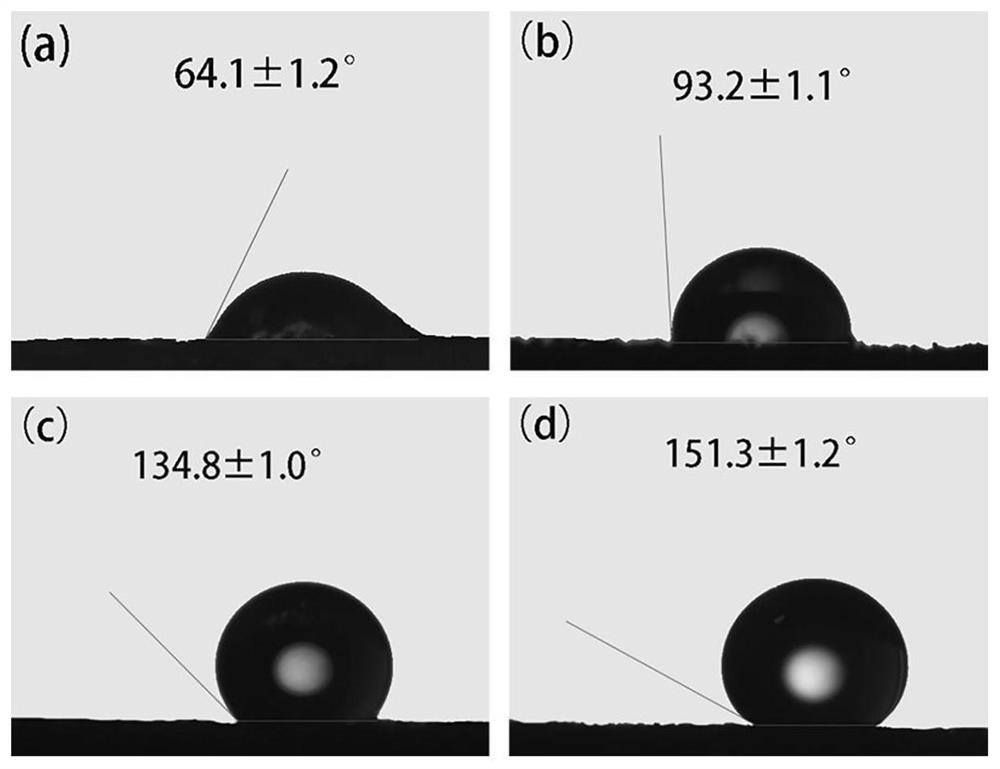

Embodiment 1

[0054] Washed successively with acetone, ethanol and distilled water to a raw polyurethane (PU) sponge, respectively ultrasonic cleaning 20min, to remove the dirt on the bone, and then placed in a vacuum oven at 80 deg.] C is placed 24h, after washing the impregnated sponge to H 2 O 2 / H 2 SO 4 A mixed solution (70% H 2 O 2 Solution was mixed with 49% H 2 SO 4 Solution volume ratio of 7: 3 the oxidation reaction), a soak time 4h, then washed with distilled water to the sponge after washing was dried in a vacuum oven dried 80 deg.] C 24h, to give PU foam rich in hydroxyl;

[0055] 50mL toluene was added to the beaker, 50mg hydroxylated nanotubes (of MWCNT) to the beaker and sonicated for 20min disperse the carbon nanotubes, a carbon nanotube dispersion liquid; octadecyltrimethylammonium added to the carbon nanotubes chlorosilane coupling agent as a coupling agent prepared at a concentration of 0.05mol / L was modified; hydroxyl-rich modified PU foam is immersed in liquid, 300rpm m...

Embodiment 2

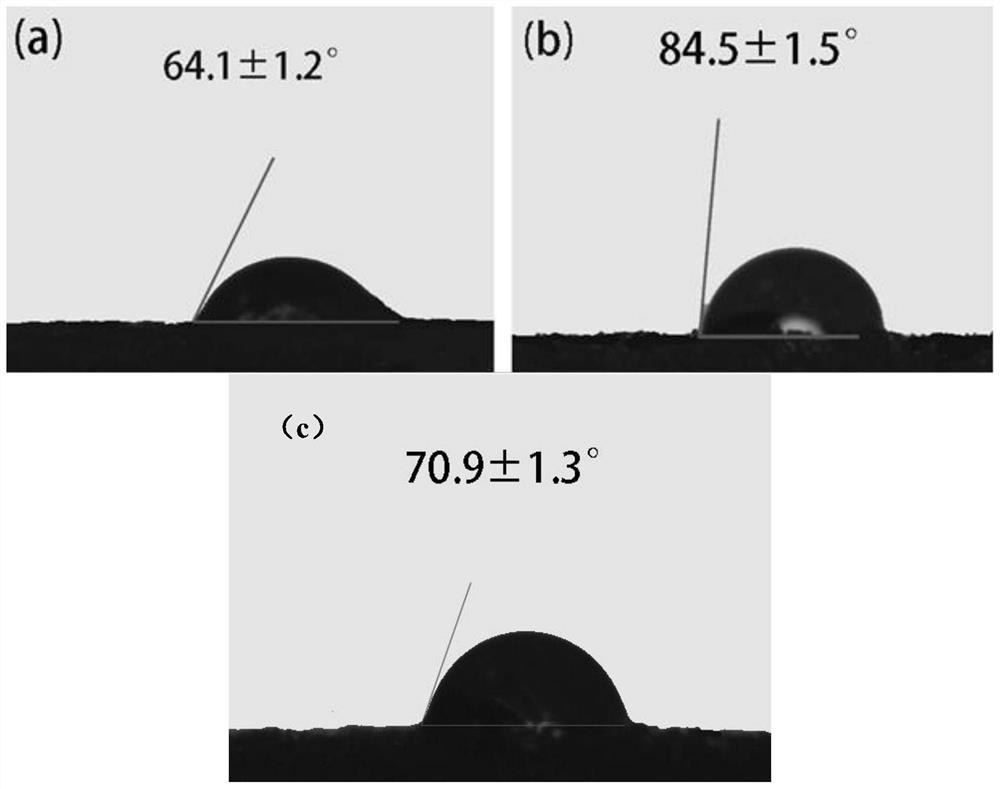

[0057] Example 1 except that, the use of hexadecyl trimethoxy silane as a silane coupling agent, the resulting product is referred to: hexadecyl trimethoxy silane -CNTs / PU sponge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com