Preparation method of polymer-coated ardealite composite master batch

A phosphogypsum and polymer technology, applied in chemical instruments and methods, dyeing low molecular organic compound treatment, dyeing high molecular organic compound treatment, etc. It can improve the dispersibility, enhance the interfacial interaction and compatibility, and improve the comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

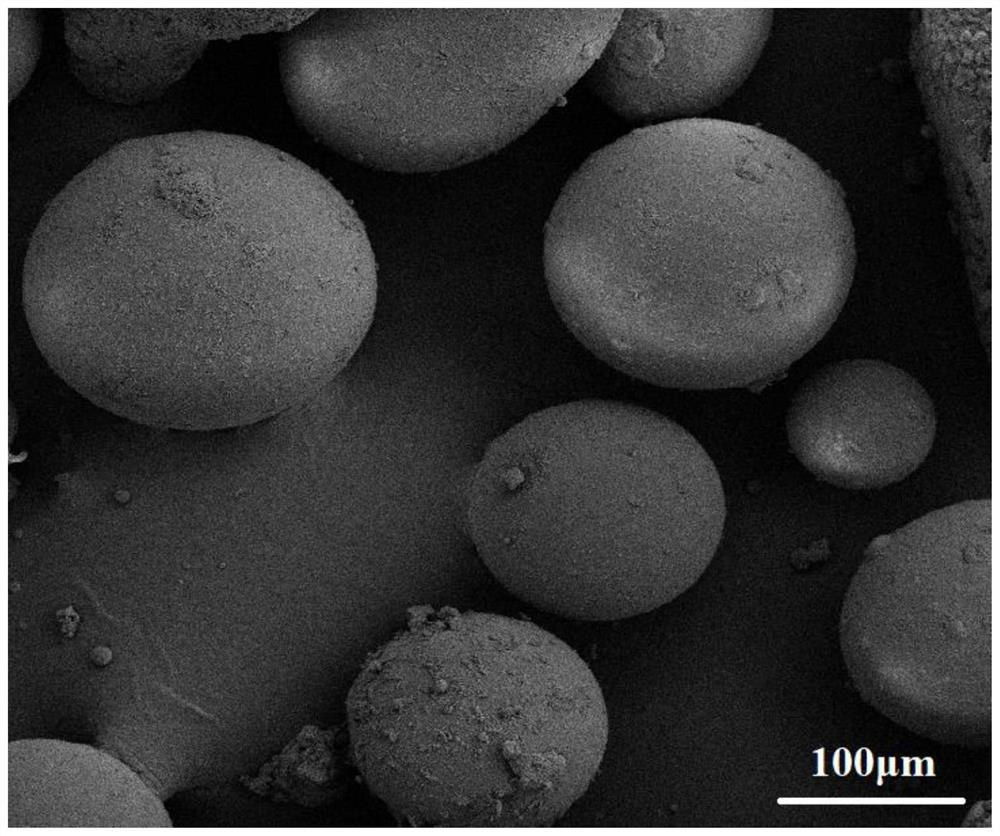

Image

Examples

Embodiment 1

[0023] A preparation method of polymer-coated phosphogypsum composite masterbatch, comprising the following steps:

[0024] S1. Put the waste phosphogypsum residue into a gradient furnace, calcinate at 600°C for 2 hours, put it into a ball mill for ball milling, the rotation speed of the ball mill is 500rpm, ball mill for 60min, and sieve to obtain anhydrous phosphogypsum. Under nitrogen atmosphere, stirring and mixing anhydrous phosphogypsum with sodium hydroxide and sodium sulfate aqueous solution to obtain a mixed liquid, which is successively filtered, washed and dried to obtain hydroxylated phosphogypsum.

[0025] S2. Add 2.0 g of neoalkoxy tris(dioctylpyrophosphate acyloxy) titanate (TCA-L38) and 7.5 mL of deionized water into 150 mL of absolute ethanol for 8 minutes of ultrasonic treatment to obtain a mixture. And place the mixture in a four-neck flask equipped with a condensing reflux device, a thermometer, a stirrer, and a nitrogen device, feed nitrogen, stir at a spe...

Embodiment 2

[0028] A preparation method of polymer-coated phosphogypsum composite masterbatch, comprising the following steps:

[0029] S1. Put the waste phosphogypsum residue into a gradient furnace, calcinate it at 550°C for 3 hours, put it into a ball mill for ball milling, the rotation speed of the ball mill is 500rpm, ball mill for 60min, and sieve to obtain anhydrous phosphogypsum. Under nitrogen atmosphere, stirring and mixing anhydrous phosphogypsum with sodium hydroxide and sodium sulfate aqueous solution to obtain a mixed liquid, which is successively filtered, washed and dried to obtain hydroxylated phosphogypsum.

[0030] S2, 3.0g TCA-L38 and 7.5mL deionized water were added to 150mL absolute ethanol and subjected to ultrasonic treatment for 8 minutes to obtain a mixture, and the mixture was placed in a condensing reflux device, a thermometer, a stirrer, and a nitrogen device. Into the four-necked flask, nitrogen gas was introduced, and the mixture was stirred at a speed of 40...

Embodiment 3

[0033] A preparation method of polymer-coated phosphogypsum composite masterbatch, comprising the following steps:

[0034] S1. Put the waste phosphogypsum residue into a gradient furnace, calcinate at 600°C for 2 hours, put it into a ball mill for ball milling, the rotation speed of the ball mill is 500rpm, ball mill for 60min, and sieve to obtain anhydrous phosphogypsum. Under nitrogen atmosphere, stirring and mixing anhydrous phosphogypsum with sodium hydroxide and sodium sulfate aqueous solution to obtain a mixed liquid, which is successively filtered, washed and dried to obtain hydroxylated phosphogypsum.

[0035] S2. Add 2.5g of TCA-L38 and 7.5mL of deionized water into 200mL of absolute ethanol and perform ultrasonic treatment for 8min to obtain a mixture. Put the mixture in a four-neck flask equipped with a condensing reflux device, a thermometer, a stirrer, and a nitrogen device, feed nitrogen, stir at a speed of 320 rpm, and heat up to 60 °C at the same time, then ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com