Preparation and use of metal-free catalysts for fixed-bed acetylene hydrochlorination to vinyl chloride

A technology of acetylene hydrochlorination and catalyst, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of ineffective and uniform utilization, low catalytic activity of metal-free catalysts, etc., and avoid collapse , Improve activity and stability, increase the effect of hydroxyl number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

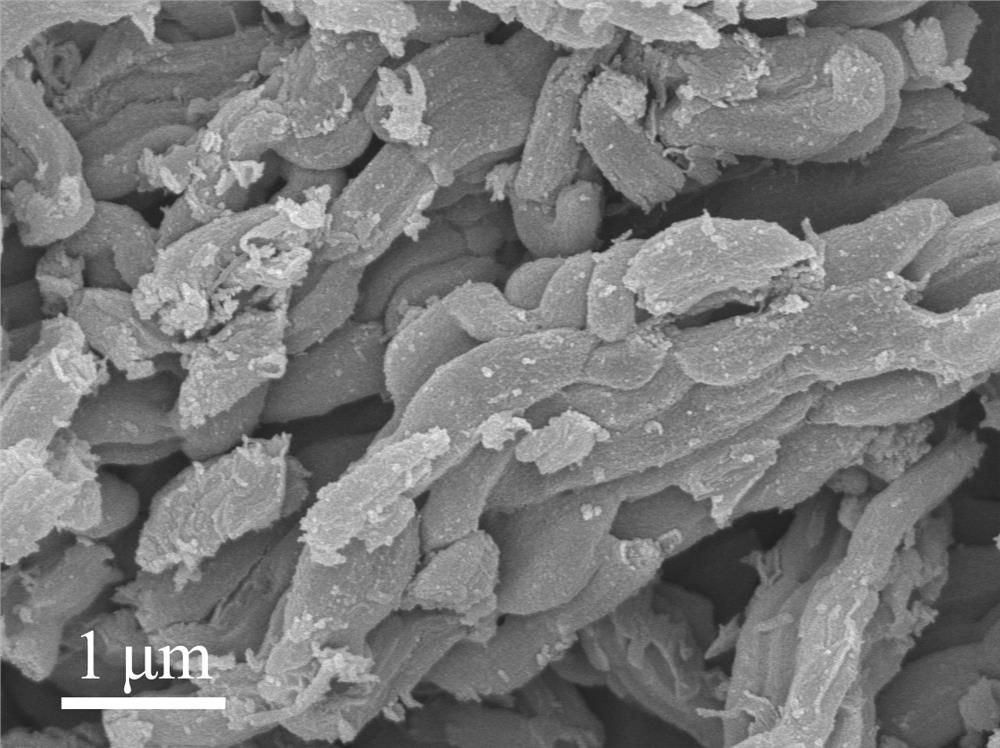

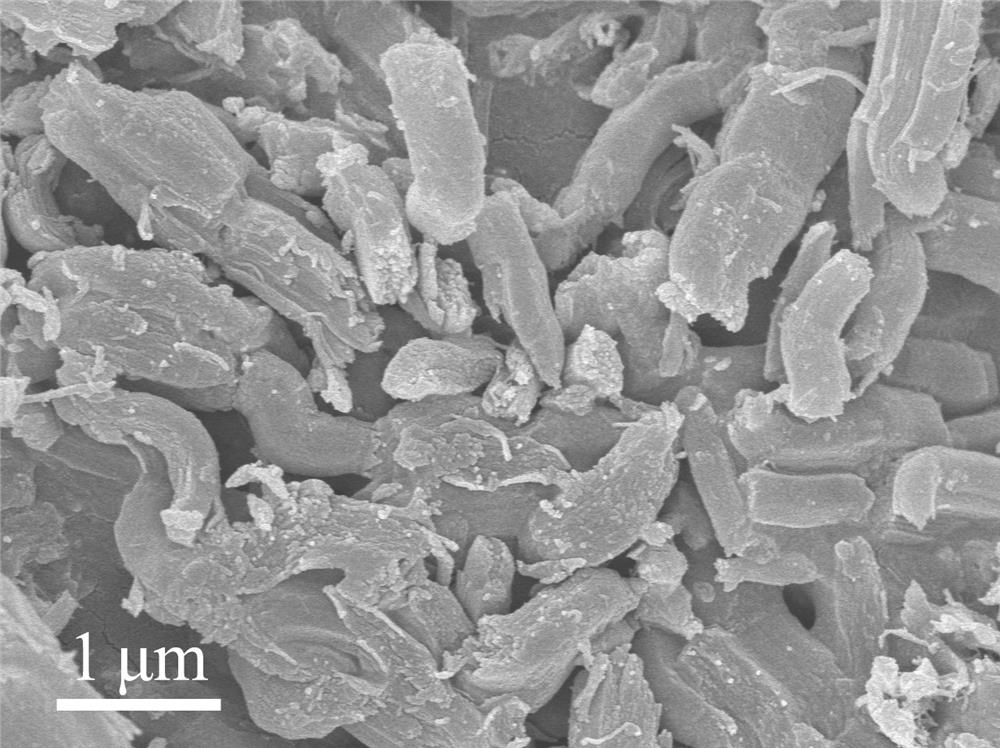

Image

Examples

Embodiment 1

[0031] (1) Add 1g of SBA-15 molecular sieve to a sulfuric acid solution with a mass concentration of 10%, stir at room temperature for more than 6 hours, then filter, separate and wash the molecular sieve to neutrality, and put the obtained filter cake at 120 ℃ Down drying obtains sample A;

[0032] (2) Under the condition of stirring at room temperature, dissolve 0.8g sucrose and 1.6g thiourea in deionized water with 1.5 times the water absorption rate of sample A to obtain a uniform solution, then add the solution to sample A and mix thoroughly, After standing still and sealed for 24 hours, the resulting mixture was transferred to a rotary evaporator and evaporated to dryness in a water bath at 60°C to obtain a precursor;

[0033] (3) Fully grind and mix 3.4g precursor and 13.6g polytetrafluoroethylene powder, transfer the mixture to an alumina tube furnace, and raise the temperature to 300 °C at a rate of 5 °C / min under a flowing inert gas atmosphere. ℃ for 1 hour, then co...

Embodiment 2

[0036] (1) Add 1g of MCM-41 molecular sieve to a sulfuric acid solution with a mass concentration of 10%, stir at room temperature for more than 6 hours, then filter, separate and wash the molecular sieve to neutrality, and put the obtained filter cake at 100 ℃ Down drying obtains sample A;

[0037] (2) Under the condition of stirring at room temperature, dissolve 1g of glucose and 3g of thiourea in deionized water with 2.5 times the water absorption rate of sample A at the same time to obtain a uniform solution, then add the solution to sample A and mix thoroughly, and statically Store in a sealed place for 24 hours, then transfer the resulting mixture to a rotary evaporator, and evaporate to dryness in a water bath at 80°C to obtain a precursor;

[0038] (3) Fully grind and mix 5g precursor and 15g polytetrafluoroethylene powder, transfer the mixture to an alumina tube furnace, and raise the temperature to 300°C at a heating rate of 10°C / min under a flowing inert gas atmosph...

Embodiment 3

[0041] (1) Add 1g of MCM-48 molecular sieve to a sulfuric acid solution with a mass concentration of 10%, stir at room temperature for more than 6 hours, then filter, separate and wash the molecular sieve to neutrality, and put the obtained filter cake at 120 ℃ Down drying obtains sample A;

[0042] (2) Under the condition of stirring at room temperature, dissolve 1.2g sucrose and 2.4g thiourea in deionized water with 2 times the water absorption rate of sample A to obtain a uniform solution, then add the solution to sample A and mix well, at room temperature After standing still and sealed for 48 hours, the resulting mixture was transferred to a rotary evaporator and evaporated to dryness in a water bath at 70°C to obtain a precursor;

[0043] (3) Fully grind and mix 4.6g precursor and 13.8g polytetrafluoroethylene powder, transfer the mixture to an alumina tube furnace, and raise the temperature to 300 at a rate of 7 °C / min under a flowing inert gas atmosphere. ℃ for 1 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com