Modified SEBS composite material for automobile injection molding interior decoration, and preparation method thereof

A composite material and interior decoration technology, applied in the field of polymers, can solve the problems of difficult molding of composite materials, affecting the fluidity of materials, and being uninvolved. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

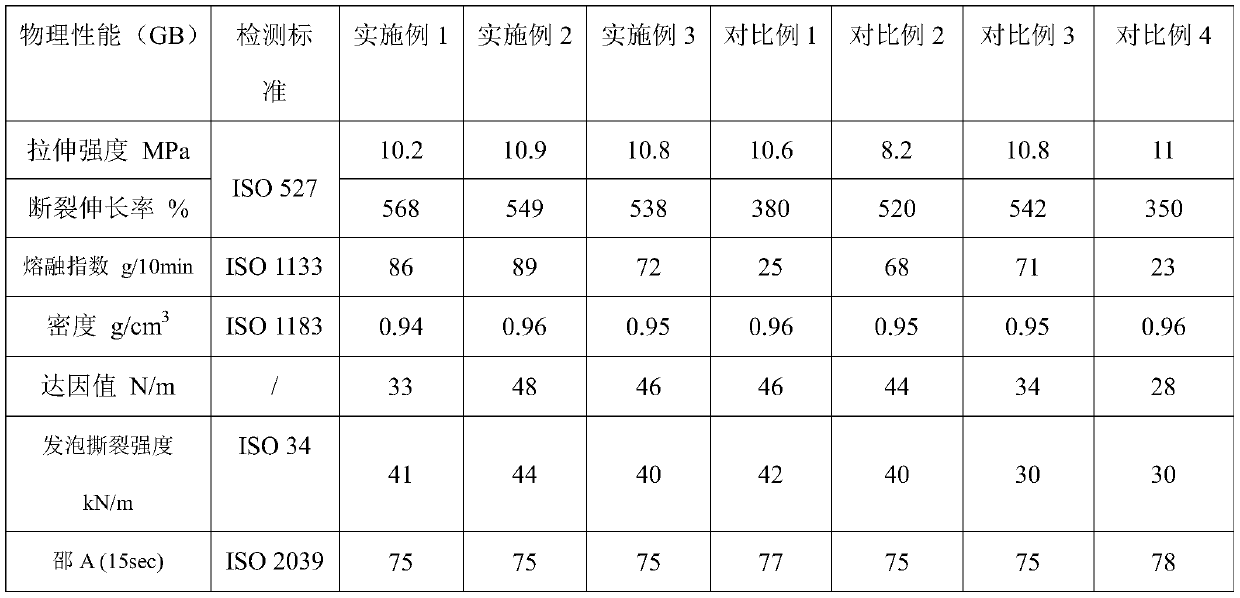

Examples

Embodiment 1

[0035] A modified SEBS composite material for automotive injection molding interior trim, is characterized in that, comprises the raw material of following weight portion:

[0036] 50 parts of hydrogenated styrene-butadiene block copolymer, 20 parts of bis(2-propylheptyl) phthalate, 3 parts of hydrotalcite, 2 parts of acetylated SEBS, 5 parts of hydroxylated SEBS, antioxidant MD-697 0.4 parts, weathering agent UV944 0.3 parts, calcium stearate 0.5 parts.

[0037]The preparation method of acetylated SEBS is as follows: the hydrogenated styrene-butadiene block copolymer is completely dissolved in methylene chloride, then anhydrous aluminum oxide is added, after stirring evenly, acetyl chloride is added for reaction, after the reaction is completed, Add anhydrous methanol for precipitation, wash the precipitate with anhydrous methanol, and vacuum-dry it to obtain it. The ratio of the weight of hydrogenated styrene-butadiene block copolymer to the volume of dichloromethane is 1g: ...

Embodiment 2

[0046] A modified SEBS composite material for automotive injection molding interior trim, is characterized in that, comprises the raw material of following weight portion:

[0047] 80 parts of hydrogenated styrene-butadiene block copolymer, 25 parts of trioctyl trimellitate, 8 parts of hydrotalcite, 5 parts of acetylated SEBS, 10 parts of hydroxylated SEBS, 0.8 parts of antioxidant 626, weather resistance agent 0.6 parts of UV326, 1 part of calcium stearate, 1 part of anti-scratch agent, 1 part of antistatic agent, and 1 part of colorant carbon black.

[0048] The preparation method of acetylated SEBS is as follows: the hydrogenated styrene-butadiene block copolymer is completely dissolved in methylene chloride, then anhydrous aluminum oxide is added, after stirring evenly, acetyl chloride is added for reaction, after the reaction is completed, Add anhydrous methanol for precipitation, wash the precipitate with anhydrous methanol, and dry it in vacuum to obtain, wherein the ra...

Embodiment 3

[0057] A modified SEBS composite material for automotive injection molding interior trim, is characterized in that, comprises the raw material of following weight portion:

[0058] 60 parts of hydrogenated styrene-butadiene block copolymer, 20 parts of trioctyl trimellitate, 6 parts of hydrotalcite, 5 parts of acetylated SEBS, 5 parts of hydroxylated SEBS, 0.25 parts of antioxidant 1790, antioxidant 0.3 parts of agent 622, 0.25 parts of weather resistance agent UV326, 0.25 parts of weather resistance agent UV944, 0.5 parts of calcium stearate, 1.5 parts of scratch resistance agent, and 0.5 parts of colorant carbon black.

[0059] The preparation method of acetylated SEBS is as follows: the hydrogenated styrene-butadiene block copolymer is completely dissolved in methylene chloride, then anhydrous aluminum oxide is added, after stirring evenly, acetyl chloride is added for reaction, after the reaction is completed, Add anhydrous methanol for precipitation, wash the precipitate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com