Asphalt modifier and preparation method thereof

A technology of asphalt modifier and rubber, applied in the field of asphalt modifier, can solve problems such as pollution, uneven modification, and hidden dangers, and achieve the effects of high safety, low processing temperature, and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

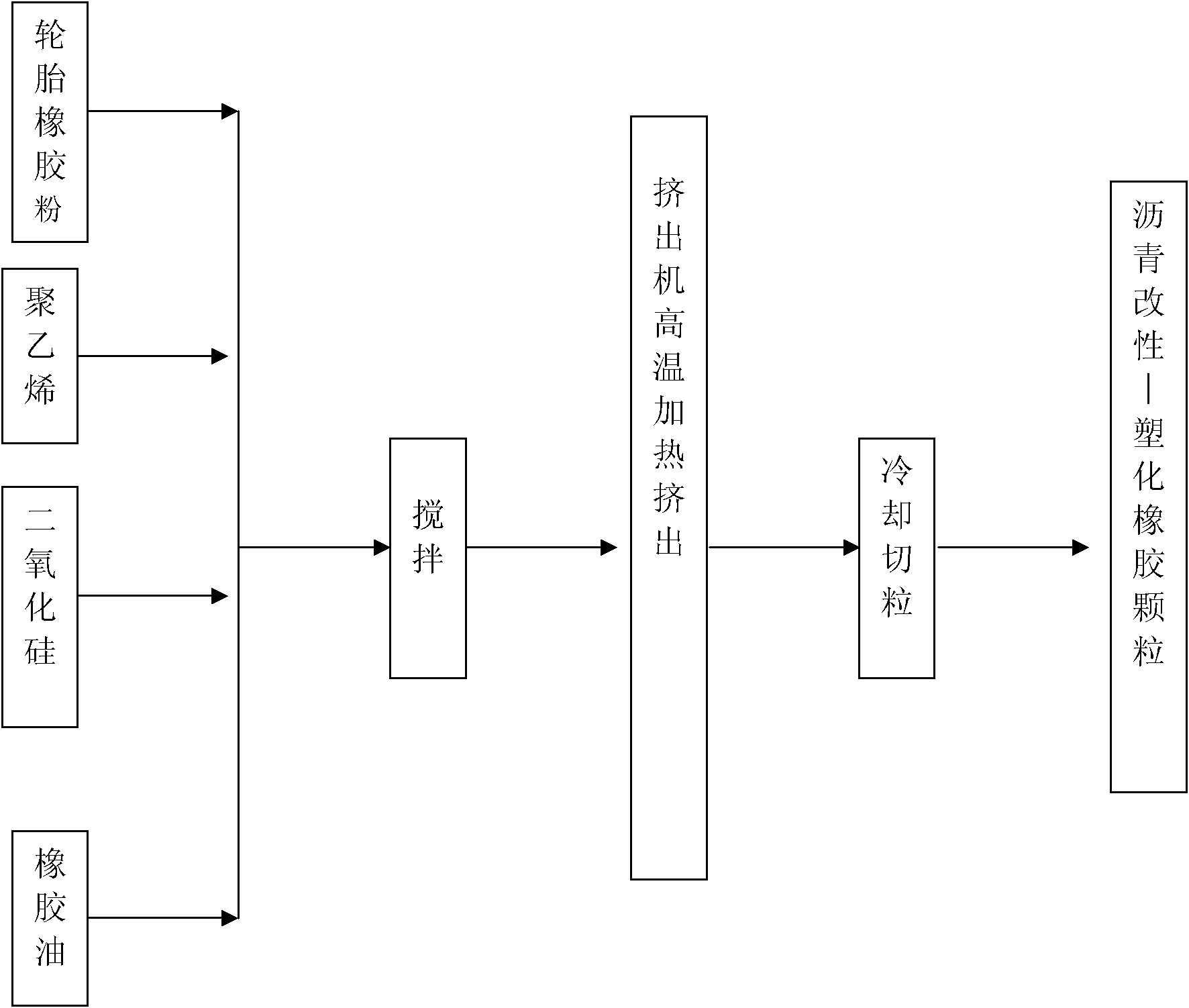

[0037] The present invention will be further described below in conjunction with accompanying drawing:

[0038] A kind of asphalt modifier of the present invention is characterized in that its component comprises tire rubber powder, polyethylene, silicon dioxide and rubber oil, the plasticized rubber viscous shape that obtains by stirring, heating, extruding, cooling section The particles are asphalt modifiers.

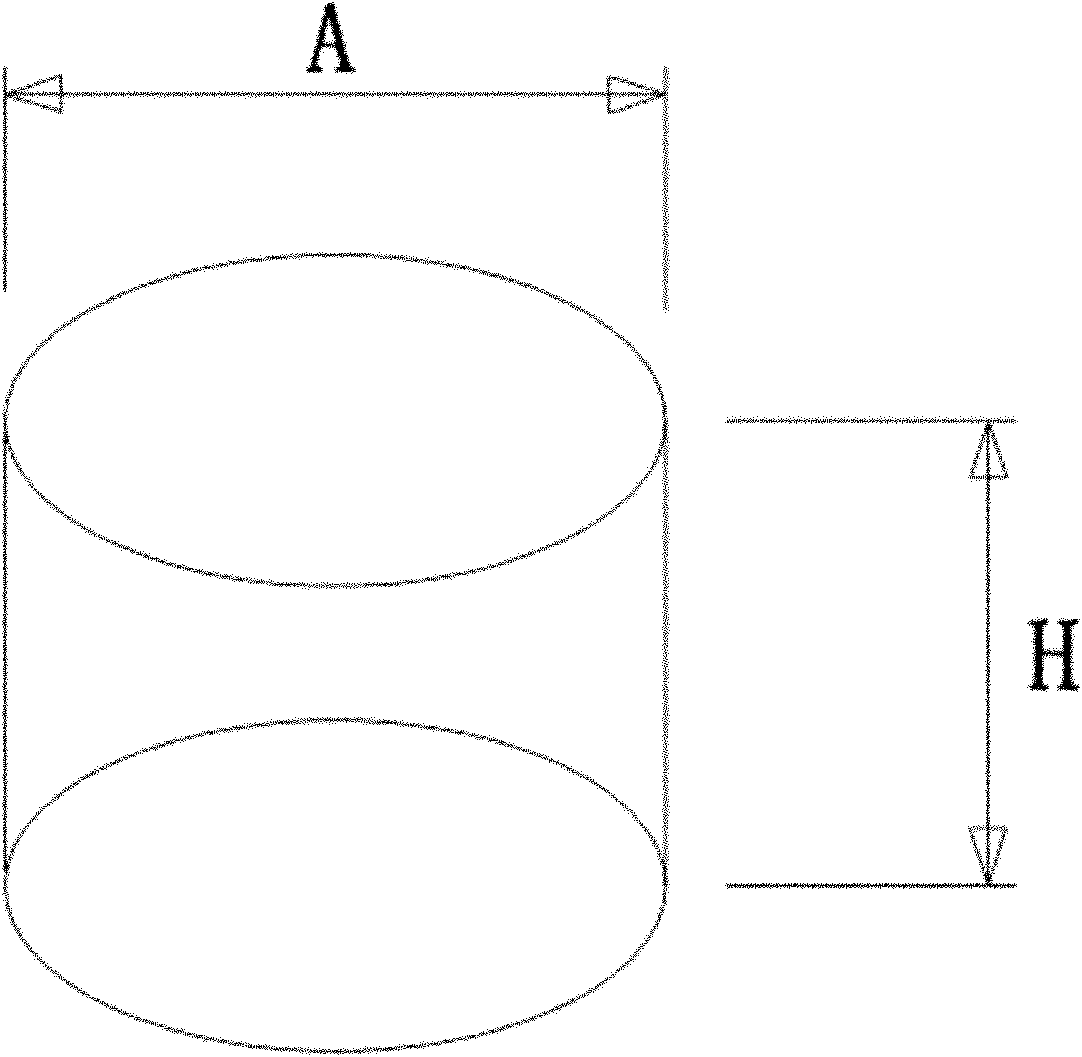

[0039] The plasticized rubber viscous particles are cylindrical, the diameter A of the cylinder is 3mm-15mm, and the height H of the cylinder is 3mm-15mm.

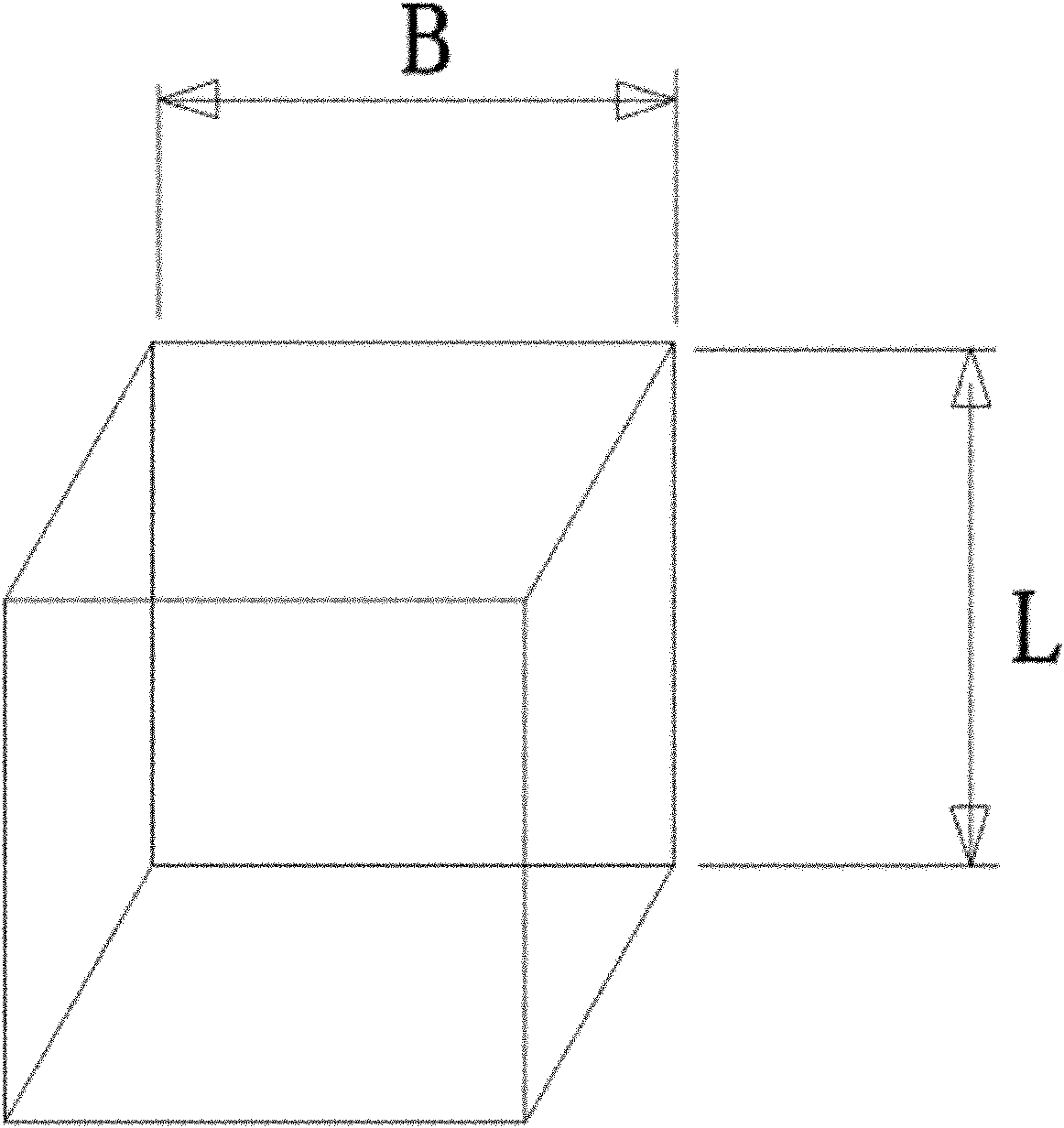

[0040] The plasticized rubber viscous particles are long strips, the width B of the strips is 3mm-15mm, and the height L of the strips is 3mm-15mm.

[0041] The tire rubber powder is 85-95 parts by weight, the polyethylene is 3-6 parts by weight, the silicon dioxide is 1-3 parts by weight, and the rubber oil is 1-7 parts by weight. The tire rubber powder, polyethylene, composite stabilizer, Silica and rubber oil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com