Transformer wire winding stripping machine

A stripping machine and transformer technology, applied in the field of transformers, can solve the problems of safety precautions increasing production costs, paint remover polluting the environment, aggravating production costs, etc., so as to reduce the possibility of work-related injuries or occupational diseases, reduce production costs, and increase safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

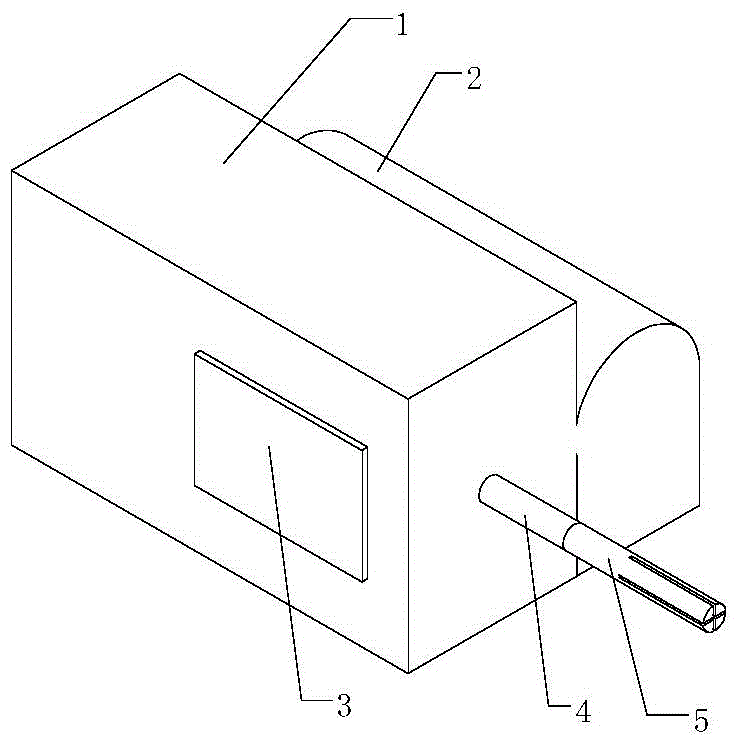

[0015] figure 1 It is a schematic diagram of the present invention, and the present invention includes an automatic winding machine 1 and an engine 2, and the engine 2 provides power for the automatic winding machine 1. The automatic winding machine 1 is provided with an operation panel 3 and a rotating shaft 4 , and the operation panel 3 can be used to control the start and stop of the automatic winding machine 1 , or to control the rotating speed of the rotating shaft 4 . In the present invention, automatic winding machine 1 is prior art, can buy finished product on the market. The present invention also includes the paint-removing terminal 5 . The paint-removing terminal 5 is installed on the rotating shaft 4, and when the rotating shaft 4 rotates, the paint-removing terminal 5 also rotates accordingly.

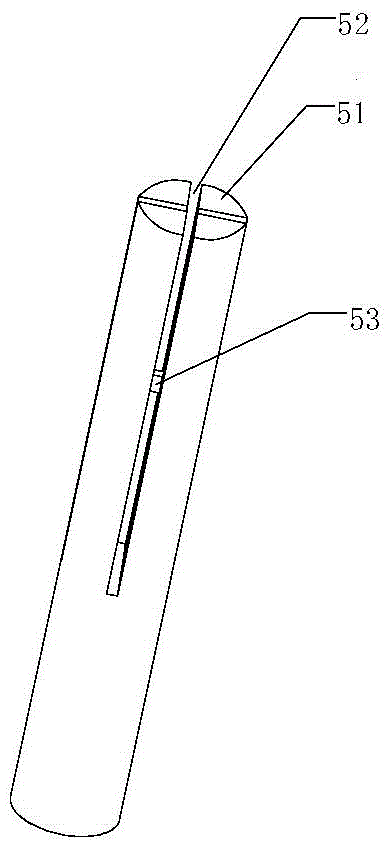

[0016] figure 2 is a schematic diagram of a stripped terminal. The paint-removing terminal 5 is cylindrical, one end of which is equally divided into four cutting kni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com