Electrical operation vehicle

A technology of electric power operation and car body, applied in the direction of lifting device, etc., can solve the problems that the working basket does not have the function of rotation and displacement in the lateral direction, the swinging and shaking of the working basket, and the limitation of the working range, so as to improve the working range and work efficiency, avoiding large-scale shaking, and avoiding unsafe accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

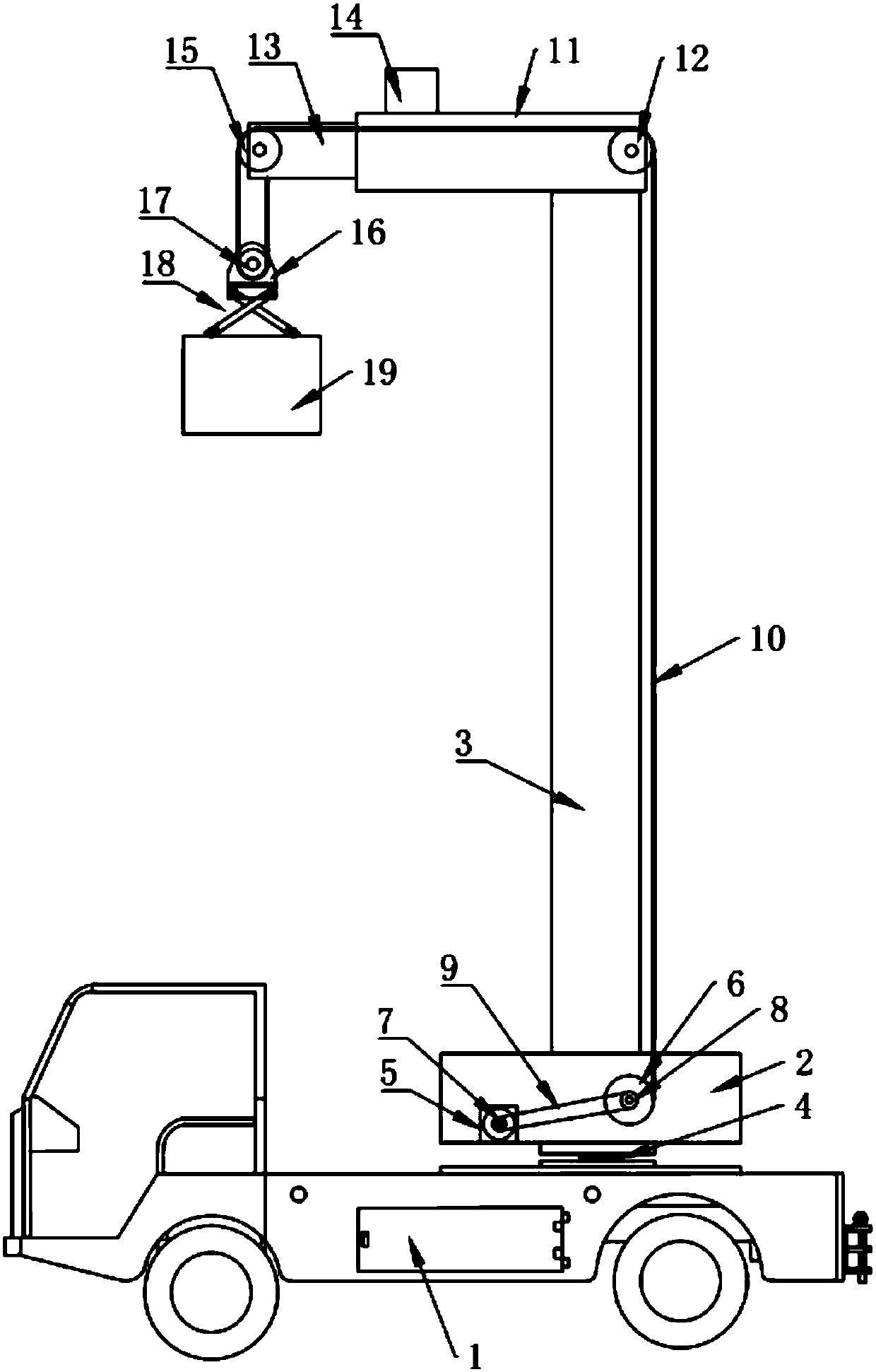

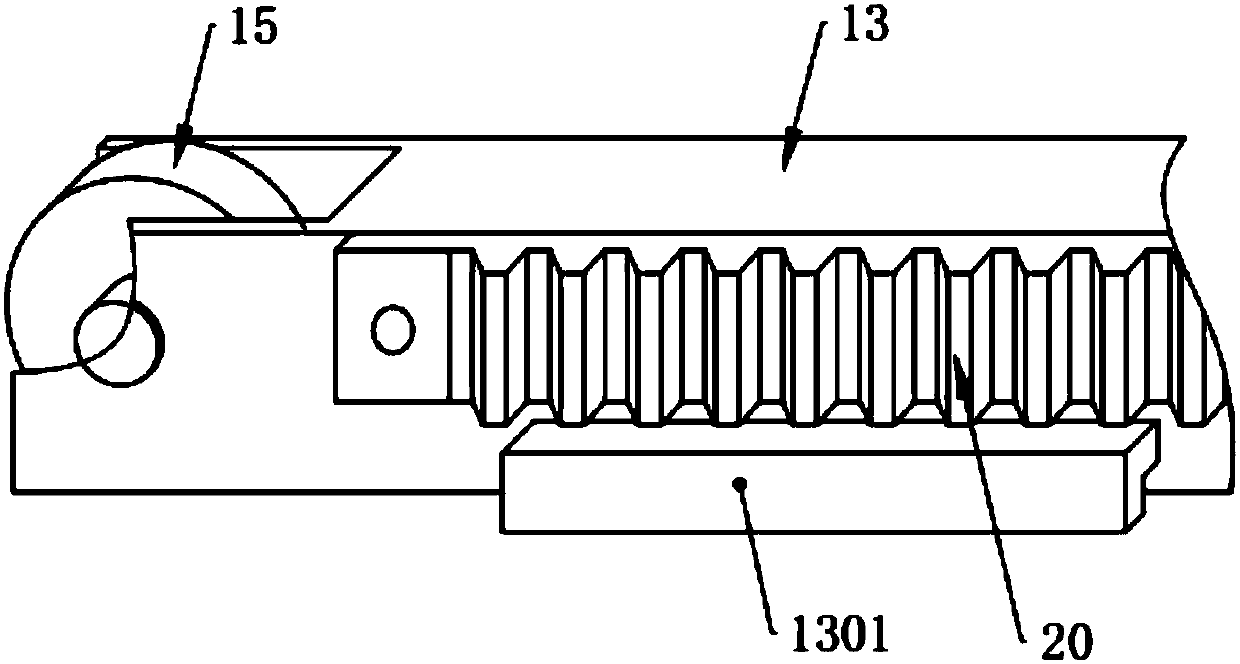

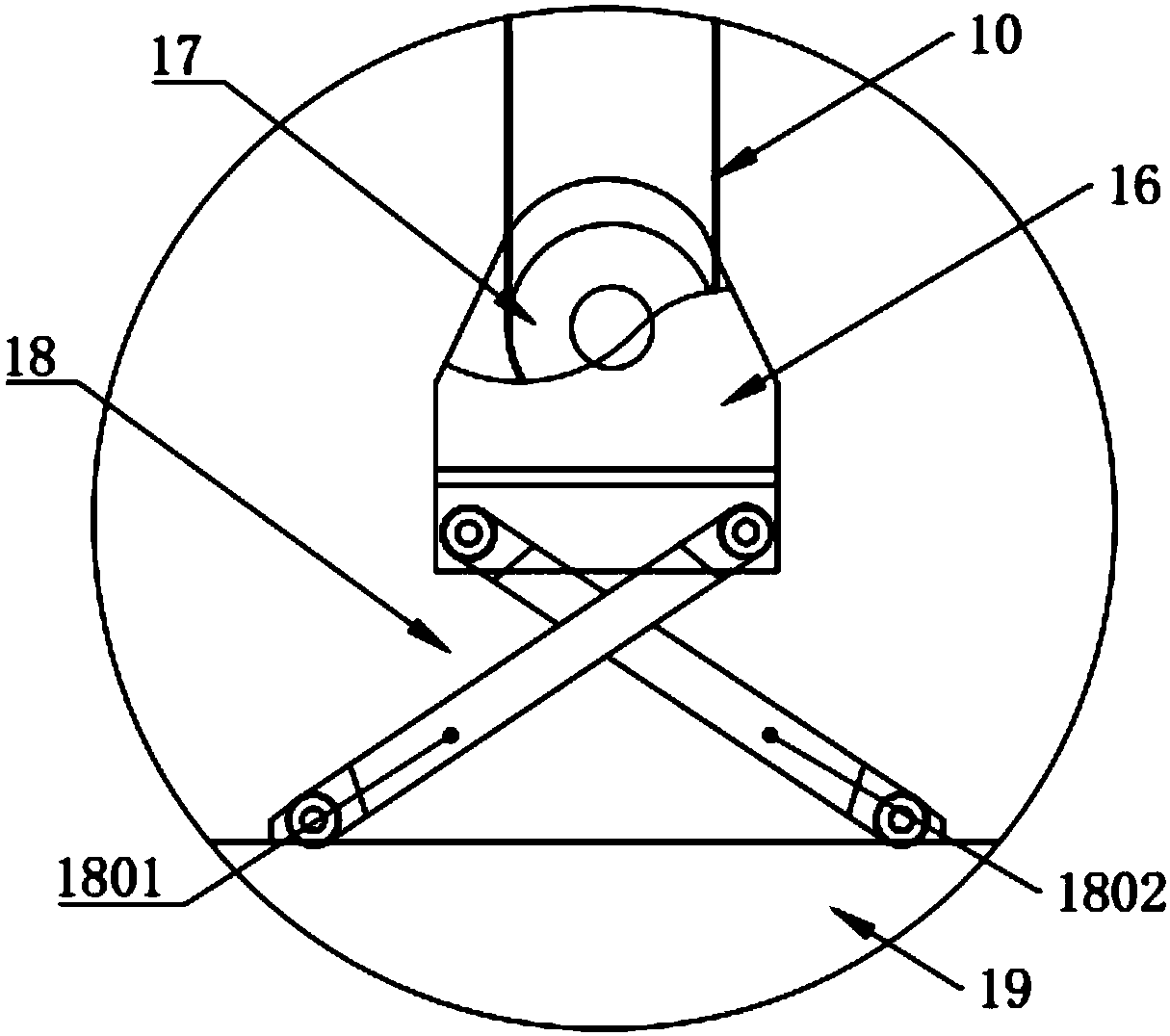

[0037] Such as Figure 1 to Figure 4As shown, the present invention provides a kind of electric work vehicle, comprises car body 1, and car body 1 is provided with mounting platform 2, and the rotating disk 4 driven by second drive motor is arranged between mounting platform 2 and car body 1, and mounting platform 2 Rotate and install on the car body 1 through the rotating disc 4. The support frame 3 and the cable winding roller 6 driven by the first power device are arranged on the installation platform 2. The cable winding roller 6 is wound with a cable rope 10 , the top of the support frame 3 is equipped with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com