Electromobile variable speed driving system and automatic variable speed control method

A technology of variable speed drive and electric vehicle, applied in the field of variable speed drive system of electric vehicle and automatic transmission control, can solve the problems of large impact, reduced riding comfort, large difference in speed ratio between two gears, etc., to reduce costs and reduce transmission loss. Small size and improved transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

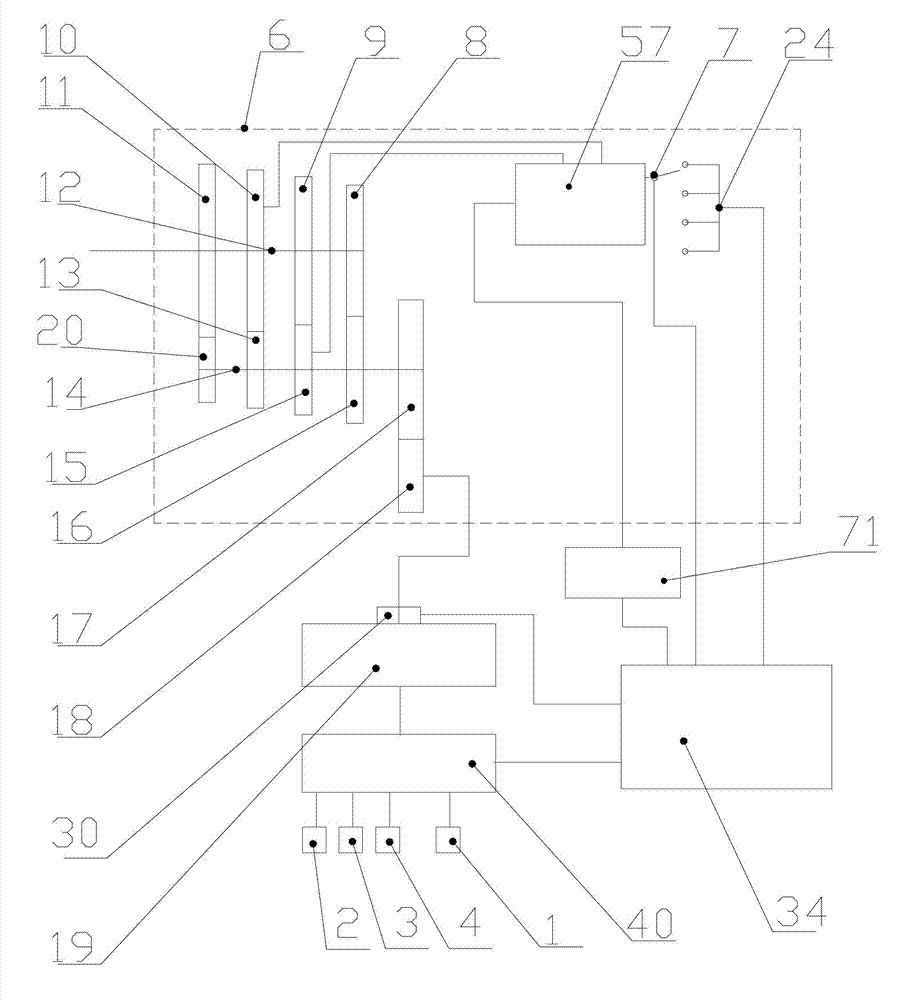

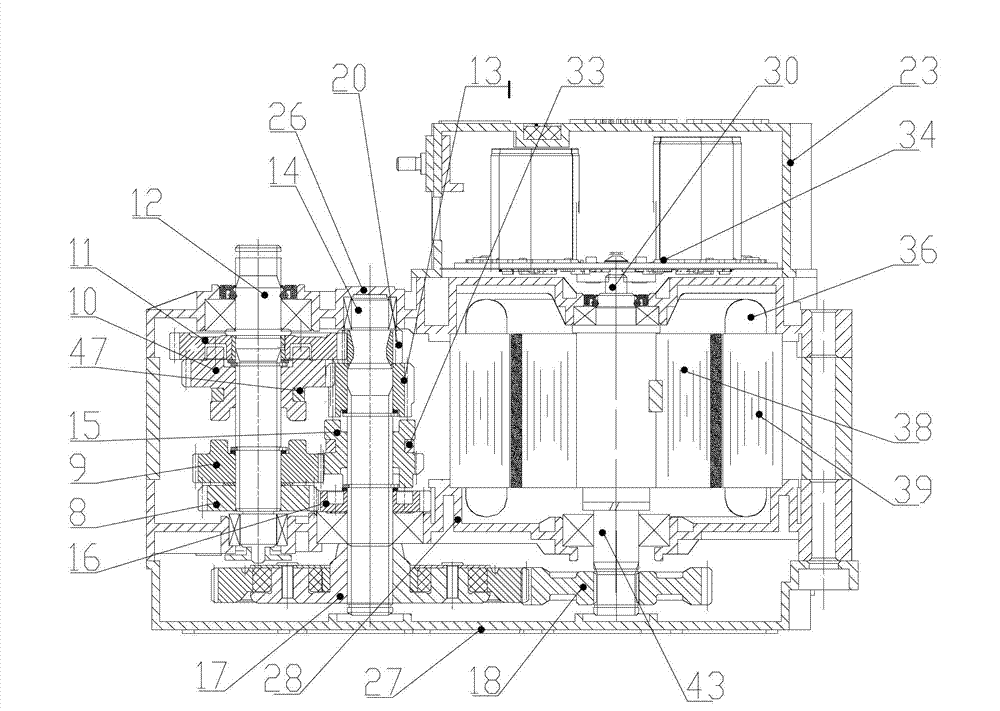

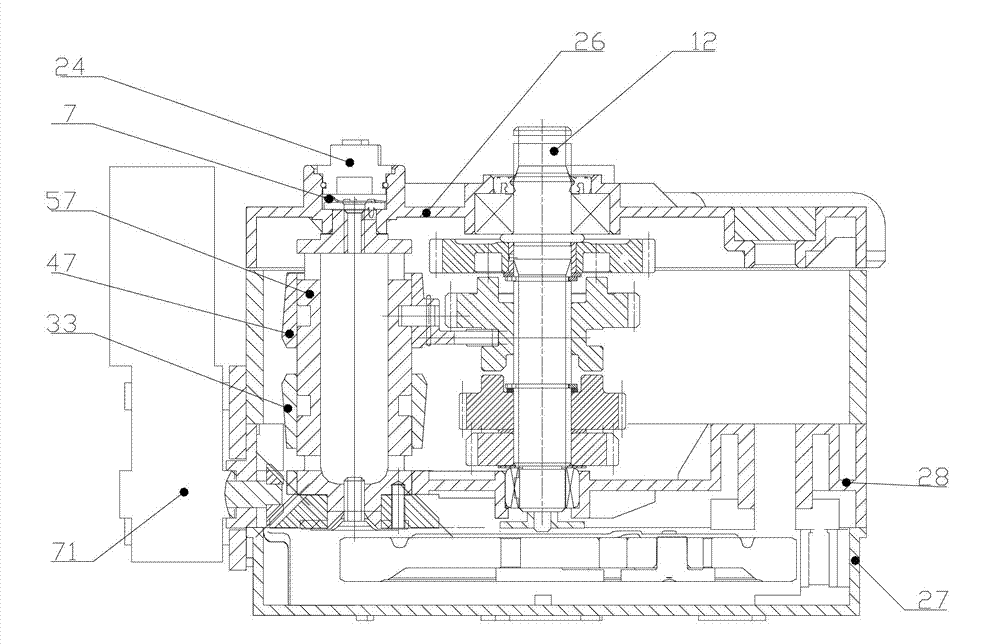

[0049] see Figure 1 to Figure 4 , an embodiment of the electric vehicle variable speed drive system of the present invention.

[0050]The electric vehicle variable speed drive system includes a drive motor 19, a motor controller 40, a multi-speed transmission 6, a shift controller 34, and the like. The lead wires of the stator three-phase winding 36 of the drive motor 19 are electrically connected to the motor controller 40 . The multi-speed transmission 6 includes a main shaft 14, a counter shaft 12, a transmission hub 57 and multiple pairs of transmission gear pairs. The main shaft 14 of described multi-speed transmission 6 is connected with the rotating shaft of driving motor 19 by gear transmission mechanism, primary driving gear 18 is installed on the rotating shaft of driving motor 19, primary driven gear 17 is installed on the main shaft 14 of multi-speed transmission, primary driven The gear 17 is in constant mesh with the primary driving gear 18, and the secondary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com