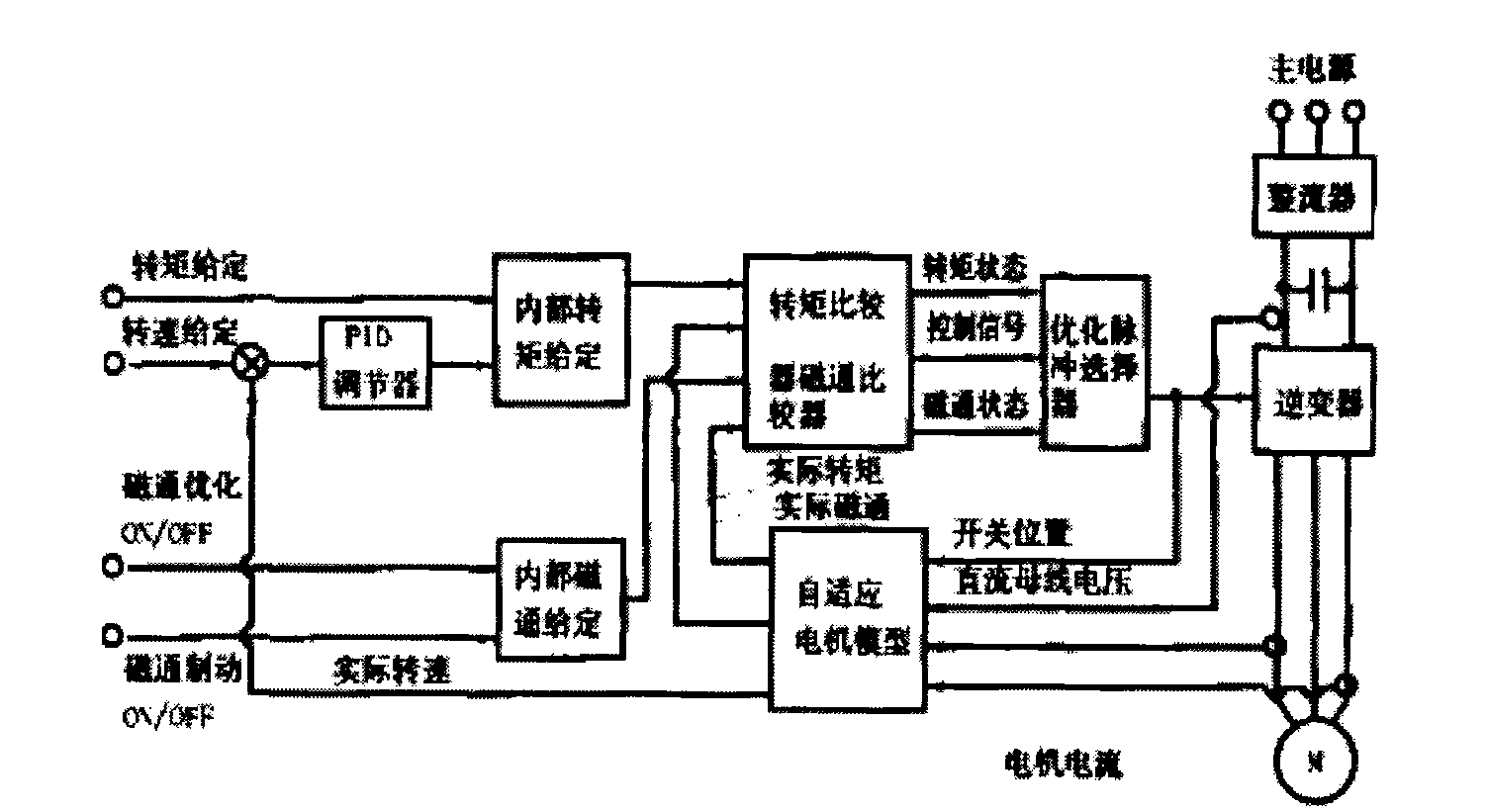

Direct torque control system

A technology of direct torque control and torque, applied in control system, AC motor control, estimation/correction of motor parameters, etc., can solve the problems of low efficiency, complex structure, clutch output power and efficiency reduction of pole-changing motors, etc. , to achieve the effect of expanding the maximum speed and increasing the range of speed regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Below in conjunction with accompanying drawing, the technical scheme realization method of invention is described: figure 1 , a direct torque control system, including PID regulator, internal torque reference, torque comparator, flux comparator, optimized pulse selector, internal flux reference, adaptive motor model, motor and main Control circuit, the output end of the internal torque setting is connected to the input end of the torque comparator / flux comparator, the speed setting is compared with the actual speed feedback and then passed through the PID regulator and the internal torque setting, the flux optimization, The magnetic flux braking is respectively connected with the internal magnetic flux given, the output of the internal magnetic flux given, the adaptive motor model is connected with the input of the torque comparator / flux comparator, and the torque comparator / flux comparator The torque state and magnetic flux state of the output end of the output end are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com