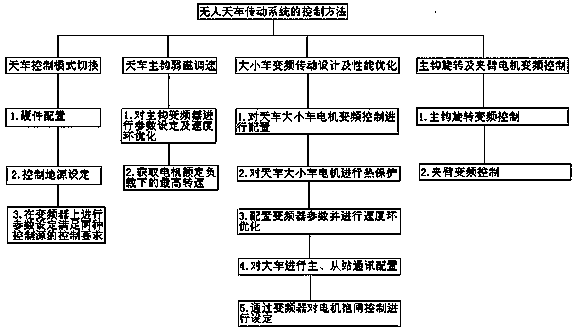

Method for frequency conversion transmission control of crown block unmanned system

A frequency conversion drive and frequency conversion control technology, which is applied in AC motor control, motor speed or torque control, and control systems, etc., can solve the problems of low control accuracy of the clamp arm, low control accuracy, and steel coil bumps. , to improve the control performance, increase the maximum speed, and suppress the swing angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

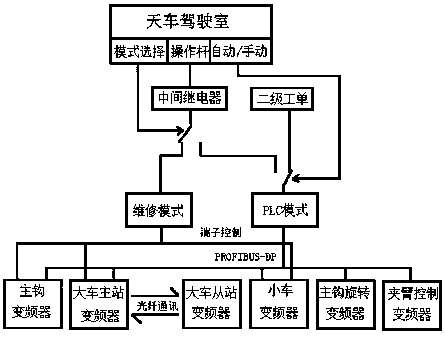

[0023] In the embodiment, the cab of the crane is equipped with a normal / maintenance mode selection switch, and the control mode switching of the large car, the trolley and the main hook can be flexibly switched through the selector switch in the cab, and the inverters of the main car owner and the trolley inverter are respectively set. Parameter p11.02 (selection of control location) is DI5, set inverter parameter P10.20 (selection of second control location) to DI5 on the main hook inverter, and the fifth digit of the DI terminal of the inverter can be set to DI.05 It is the selection instruction of the first control ground source and the second control ground source. The cab mode switching switch realizes mode switching by controlling the input of the fifth terminal DI.05 of the frequency converter, thus realizing the terminal and DP network ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com