Electric driving bogie for subway engineering vehicle

A subway engineering vehicle, electric drive technology, applied in the direction of bogies, railway car body parts, transmission devices driven by electric motors, etc., can solve the problems of high cost of bogie configuration, difficulty in adding power equipment, and increase in manufacturing and maintenance costs, etc. Achieve the effect of increasing maximum operating speed, solving poor performance, and reducing manufacturing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

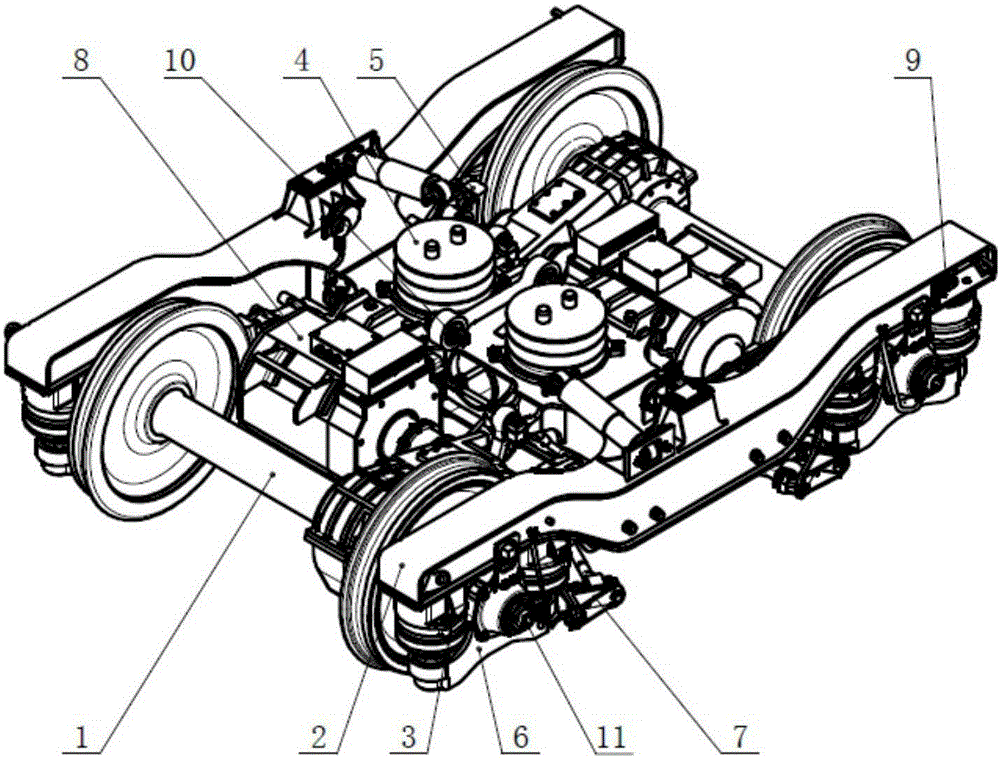

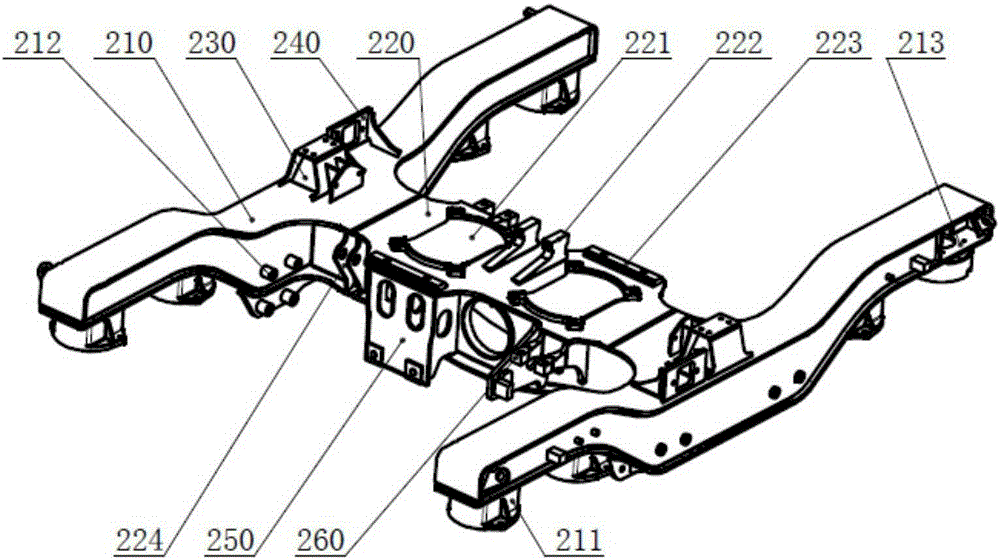

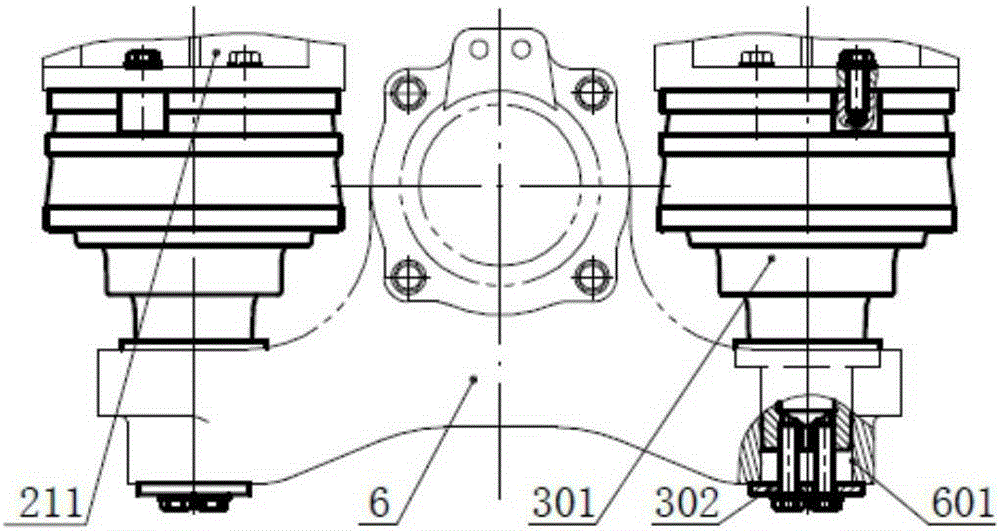

[0045] Such as figure 1As shown, the present invention includes two wheel pairs 1, a frame 2, four primary suspension systems 3, a secondary suspension system 4, a set of braking devices 5, four axle boxes 6, and a set of wheel pair connecting devices 7. One set of electric driving device 8, one set of weighing device 9, traction device 10, two grounding devices 11. The axle box 6 is installed at both ends of each wheel pair 1; the primary suspension system 3 is vertically installed between the axle box 6 and the frame 2; the secondary suspension system 4 is installed on the frame 2; The device 5 is installed inside the frame 2; the wheel pair connection device 7 is installed on the lower part of the axle box 6; the electric drive device 8 is installed on the wheel pair 1 and the frame 2; the weighing device 9 is installed at the end of the frame 2; T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com