Two-speed transmission for pure electric vehicle and speed changing method

A pure electric and transmission technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of single-speed gearbox that is difficult to balance power, efficiency, maximum speed, physical discomfort of passengers, and driving safety factor Low-level problems, to achieve the effect of flexible and efficient vehicle torque transmission, high transmission efficiency, and improved comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

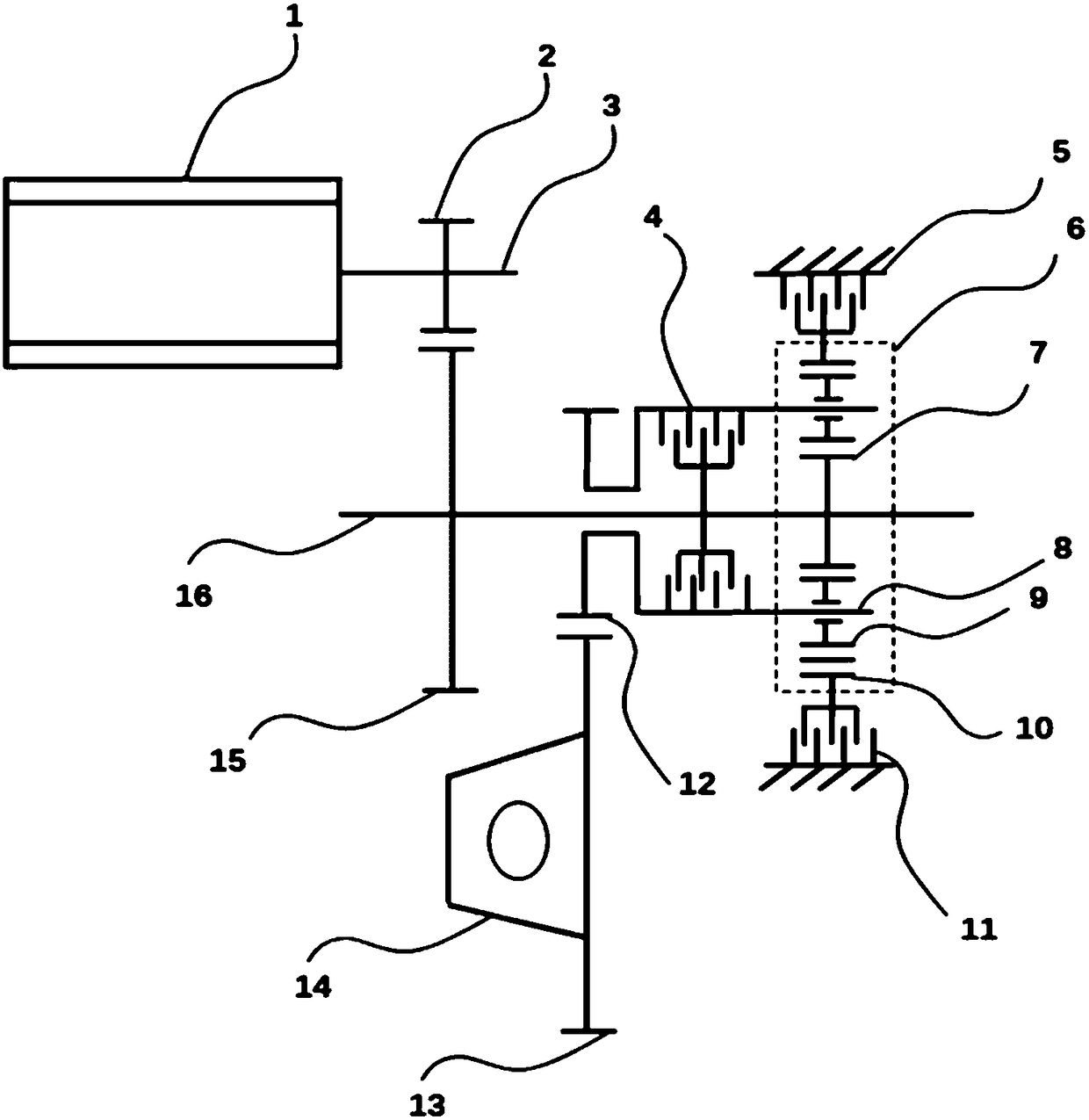

[0032] A two-speed transmission for pure electric vehicles, such as figure 1 As shown, it includes a transmission housing 5, which includes a drive motor 1, an input gear 2, an input shaft 3, an intermediate shaft 16, an intermediate gear 15, a planetary gear train 6, a first power module, a second power module, and a differential device 14;

[0033] The drive motor is splined to the input shaft, the input shaft is provided with the input gear, the intermediate shaft is provided with an intermediate gear and a sun gear 7, and the intermediate gear meshes with the input gear; The planetary gear train includes a planet carrier 8, the sun gear, a planetary gear 9 and a ring gear 10;

[0034] The first power module includes a first clutch 4 and the sun gear, the first clutch is provided with a first inner ring and a first outer ring, the first inner ring is fixedly connected with the intermediate shaft, and the the first outer ring is fixedly connected with the planet carrier; ...

Embodiment 2

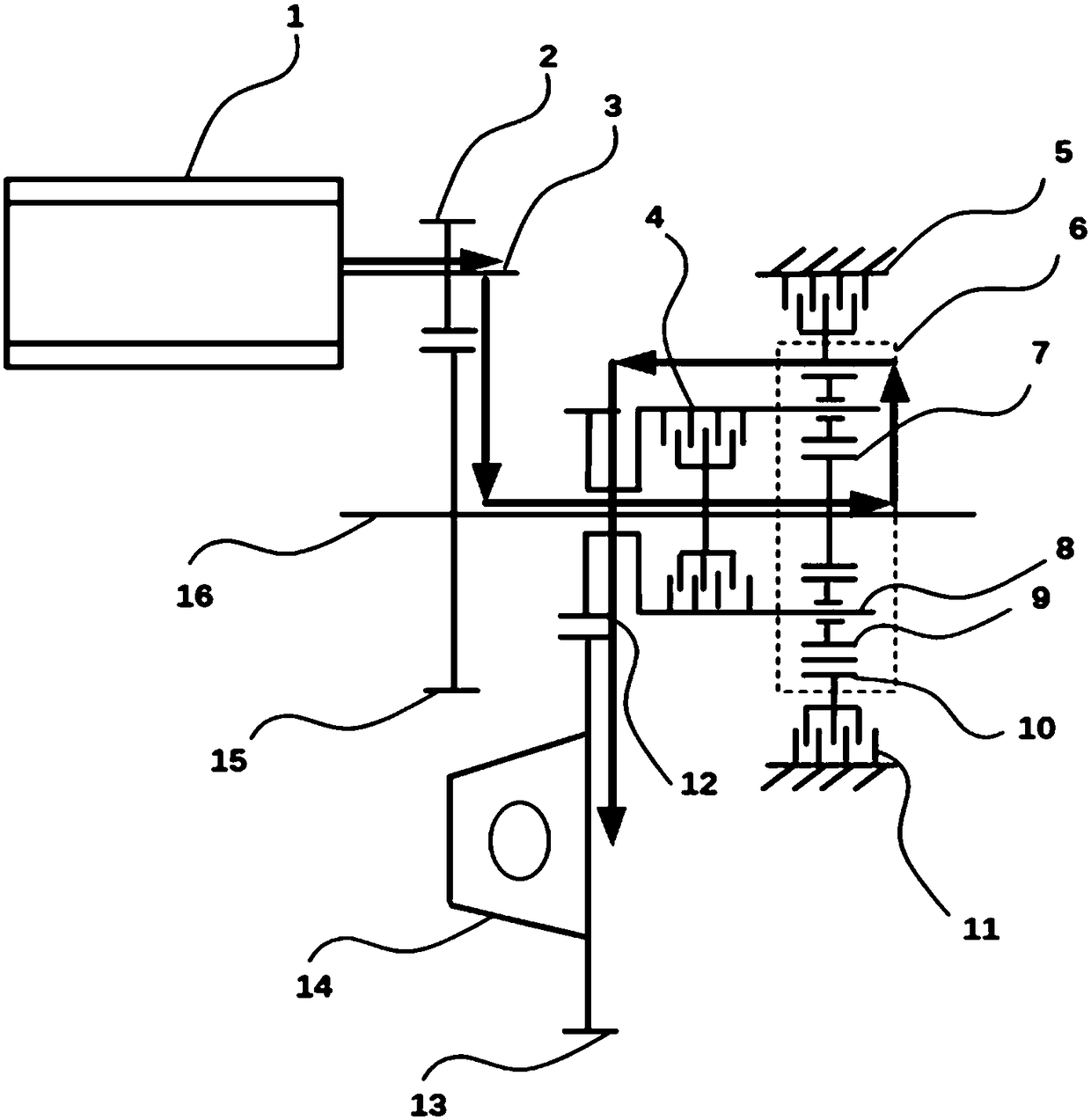

[0039] The present invention also provides a dual motor driving method, such as Figure 2-Figure 4 shown, including the following steps:

[0040] S1. During the acceleration stage of the vehicle, the two-speed transmission is in the first-speed working state. At this time, the vehicle obtains the maximum transmission ratio and transmits torque. When the vehicle accelerates, the first clutch is disengaged, the second clutch is engaged, and the drive The torque of the motor is transmitted to the input gear through the input shaft, and the input gear and the intermediate gear transmit the torque to the intermediate shaft through gear meshing, and the intermediate shaft is synchronized with the sun gear, thereby transmitting the torque It is transmitted to the main reduction input gear, and then transmitted to the main reduction output gear through gear meshing, and finally the torque is transmitted to the vehicle wheels through the differential to drive the vehicle to start and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com