Compact double-motor driving system and driving method

A dual-motor drive, compact technology, applied in the direction of electric vehicles, control drives, electric power devices, etc., can solve the problem of single-speed gearboxes that are difficult to balance power, efficiency, maximum speed, high gearbox cost, and layout space Large and other problems, to achieve the effect of flexible and efficient vehicle torque transmission, light weight of the vehicle body, and saving development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

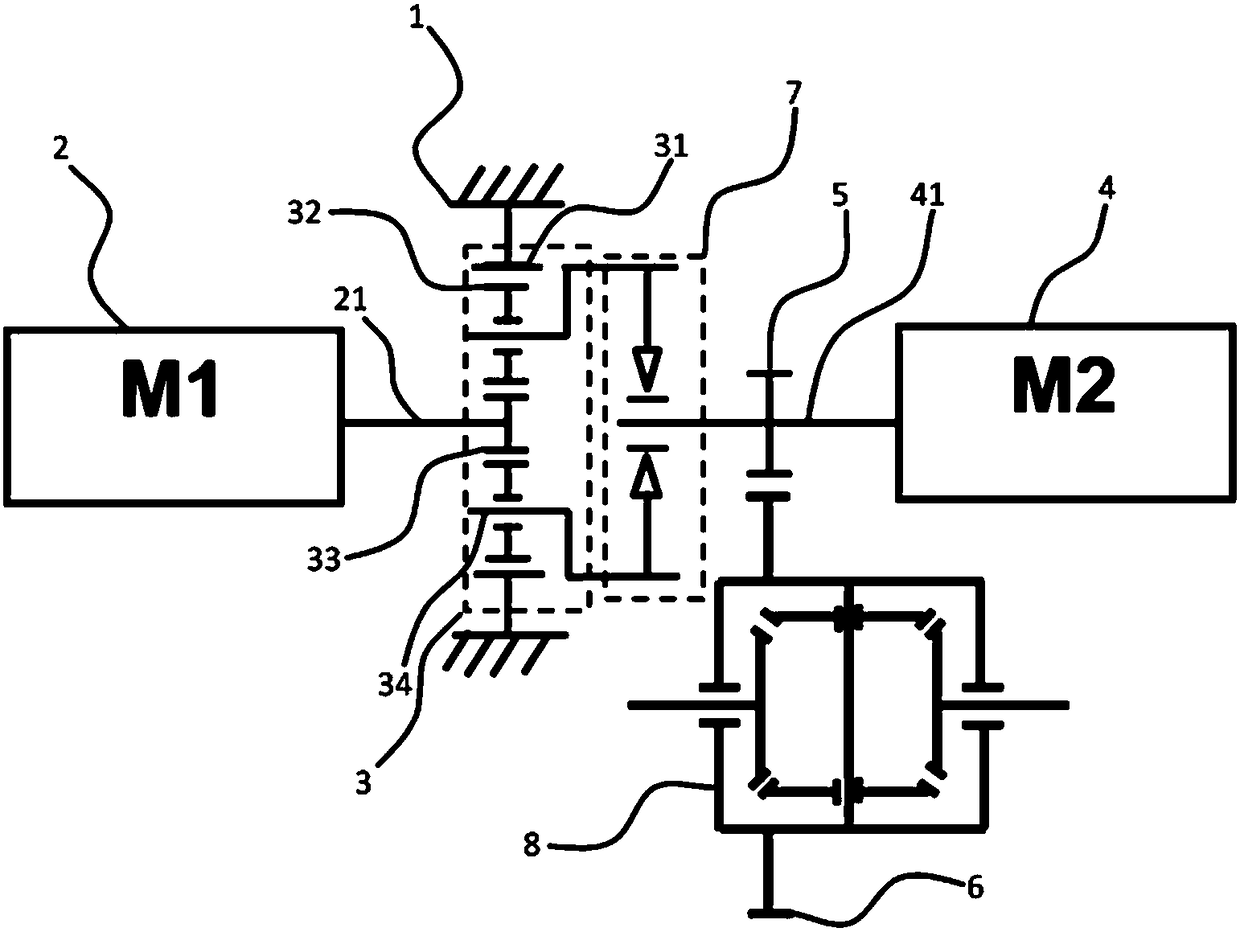

[0043] A compact dual motor drive system such as figure 1 As shown, it includes a drive housing 1, and the dual-motor drive system includes a first power module, a second power module and a one-way clutch 7;

[0044] The first power module includes a first drive motor 2 , a first input shaft 21 and a planetary gear train 3 , the first drive motor is splined to the first input shaft, and the planetary gear train includes a ring gear 31 , a planetary gear 32, a sun gear 33 and a planet carrier 34, the ring gear is fixedly connected to the drive housing, and the sun gear is arranged on the first input shaft;

[0045] The second power module includes a second drive motor 4, a second input shaft 41, a final reduction input gear 5 and a final reduction output gear 6, the second drive motor is splined to the second input shaft, and the The main reduction input gear is arranged on the second input shaft, and the main reduction output gear meshes with the main reduction input gear;

...

Embodiment 2

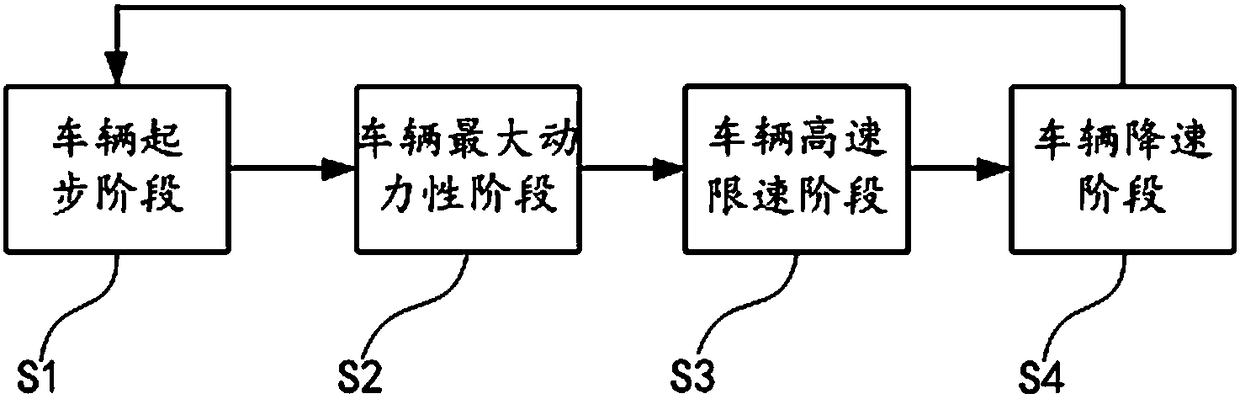

[0051] The present invention also provides a dual-motor driving method, such as Figure 2-Figure 4 shown, including the following steps:

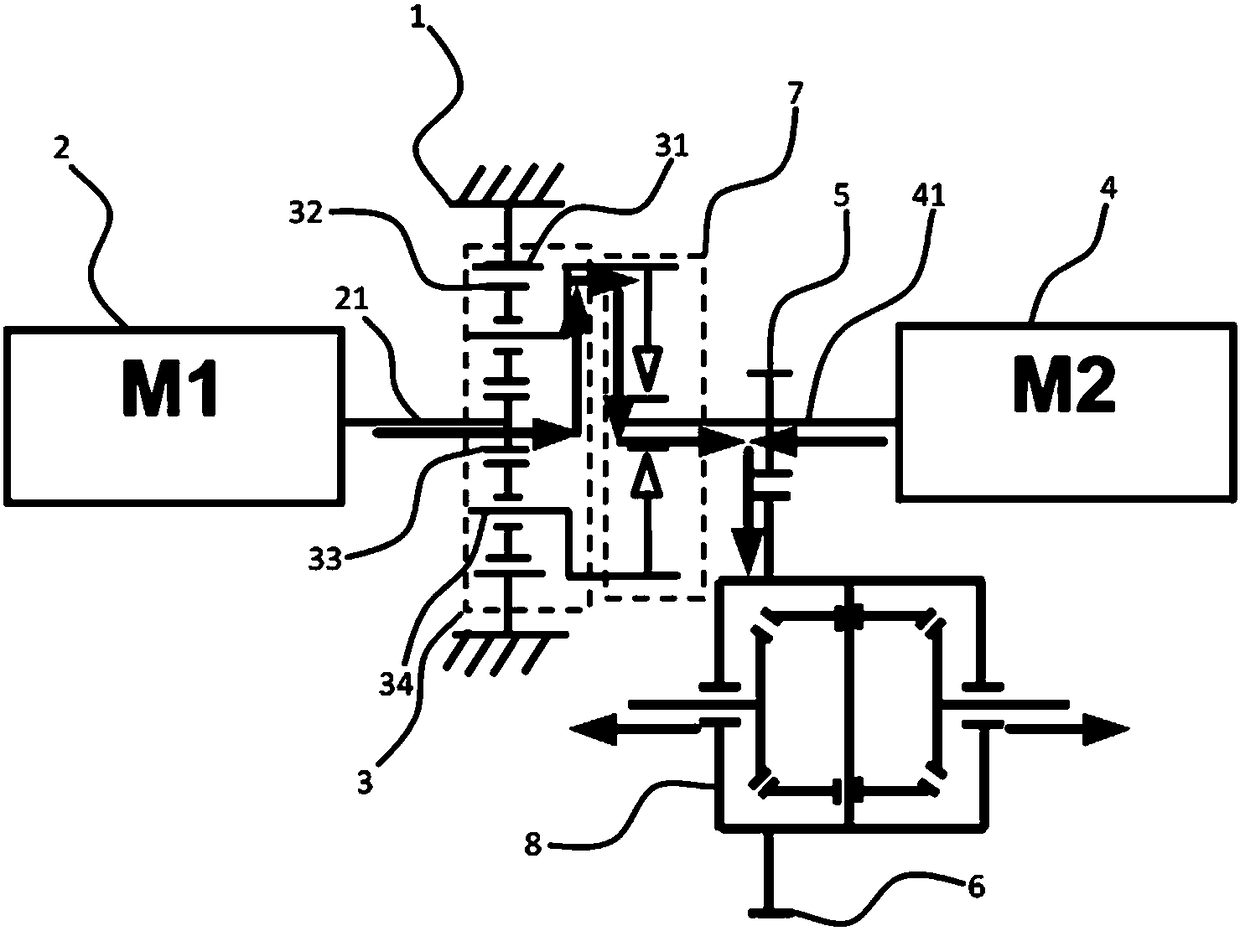

[0052] S1. During the starting phase of the vehicle, the first drive motor and the second drive motor output torque at the same time, and the first drive motor transmits the torque to the one-way clutch through the planetary gear train, and then transmits the torque to the one-way clutch transmitted to the second input shaft, torque transmission is illustrated as image 3 as shown, image 3 The middle arrow is the direction of torque transmission;

[0053] S2, the maximum power stage of the vehicle, the torque of the first driving motor and the torque of the second driving motor are superimposed through the second input shaft and are jointly transmitted to the differential through the final reduction input gear , and then drive the vehicle wheel to roll with maximum power;

[0054]S3. In the high-speed stage of the vehicle, the actual s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com