Compensation voltage algorithm of inverter dead zone in motor control system and interpolation method

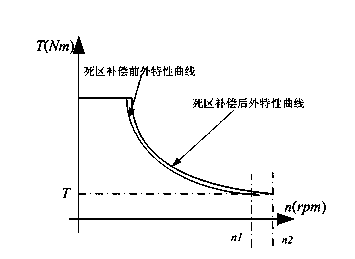

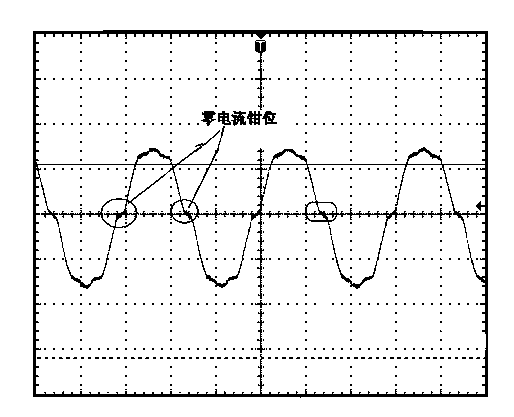

A technology for compensating voltage and motor control, which is applied in the control system, vector control system, motor generator control, etc. It can solve the problem of increasing the harmonic content of the output current of the inverter, increasing the flux distortion of the motor and torque ripple, and inverter It is impossible to fully compensate for the dead zone effect of the device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

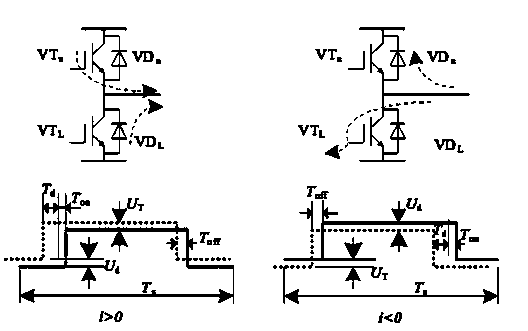

[0039] The compensation voltage algorithm of the inverter dead zone in the motor control system of the present invention comprises the following steps:

[0040] Step 1. Considering the inverter dead zone delay time T d , Inverter power tube turn-on time T on , off time T off 1. Under the influence of the conduction voltage drop of the power tube and the conduction voltage drop of the diode, taking the U phase of the inverter as an example, in a PWM cycle, calculate the error of the dead zone effect of the inverter according to the fact that the ideal and actual volt-second areas are equal time T err for:

[0041] T err =(T d +T on -T off +T ave )*sgn(i U ) (1)

[0042] in T ave = T on U d + ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com