Planetary wheel numerical control polishing removal function generator

A function generation and planetary gear technology, which is used in grinding/polishing equipment, grinding machines, metal processing equipment, etc., can solve the problems of unstable flexible shaft transmission, limited removal function efficiency and stability, poor transmission rigidity, etc. Transmission stiffness and rotation stability, overcoming the unsteady transmission of flexible shafts, and improving the effect of rotational symmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

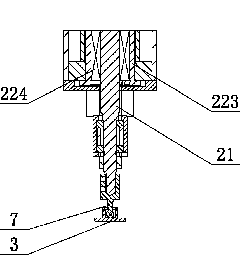

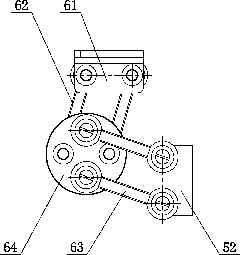

[0030] Such as Figure 1 to Figure 5 As shown, the planetary wheel type numerical control grinding and polishing removal function generating device of the present invention includes a revolution shaft system 1, a rotation shaft system 2, a polishing disc 3, an eccentric adjustment mechanism 4 and a rotary mechanism 5, and the revolution shaft system 1 is connected to the eccentric adjustment mechanism Above 4, the slewing mechanism 5 is connected to the bottom end of the eccentric adjustment mechanism 4, the rotation shaft 2 is connected to the bottom of the slewing mechanism 5, and the polishing disc 3 is installed at the lower end of the rotation shaft 2.

[0031]In this embodiment, the revolving shaft system 1 includes a revolving shaft 11, a revolving shaft base 12, a revolving motor 13 and a revolving synchronous belt 14, the revolving shaft 11 is installed in the revolving shaft base 12, and the revolving motor 13 is installed in the revolving shaft On the base 12 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com