Synchronous reluctance motor rotor applied to hybrid power system

A technology of synchronous reluctance motor and hybrid power system, applied in the direction of synchronous machine parts, electrical components, electromechanical devices, etc., can solve the problems of reduced bearing life, shortened motor life, narrow constant power speed regulation range, etc., to reduce the use of Quantity, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The concrete implementation method of the present invention is as follows:

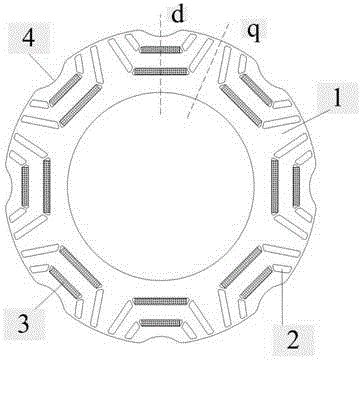

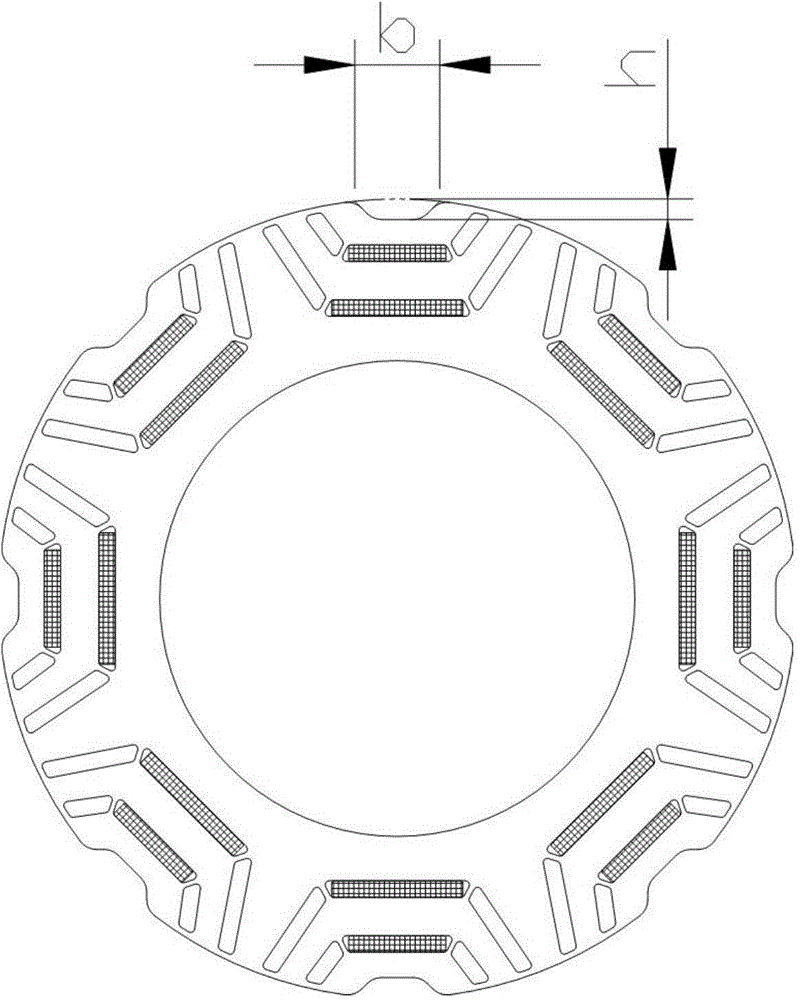

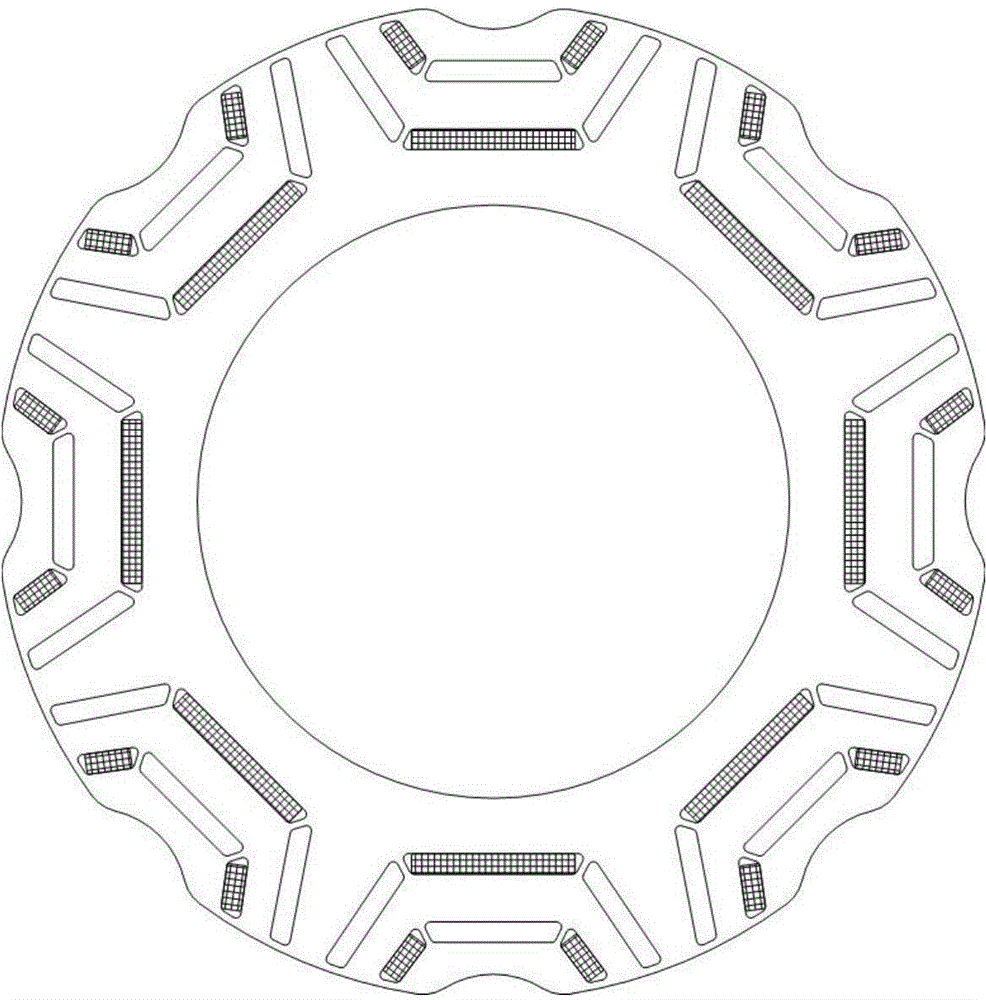

[0025] The synchronous reluctance motor rotor provided by the present invention has multiple sets of permanent magnet slots, and each set of permanent magnet slots includes a multi-layer grid. The so-called "grid" in this article refers to the groove-like structure set on the rotor core or the structure penetrating through the rotor core in the axial direction, similar to the magnetic pole slot of the permanent magnet synchronous motor, but the grid can be filled or not filled Permanent magnet material; the so-called "saliency ratio" in this article refers to the ratio of the motor's quadrature axis inductance to the direct axis inductance. The magnetic properties of the permanent magnets in the same permanent magnet slot group of the motor rotor of the present invention are the same, and the magnetic properties of the permanent magnets between adjacent permanent magnet slot groups are opposite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com