Birotor permanent magnet synchronous reluctance motor and configuration method

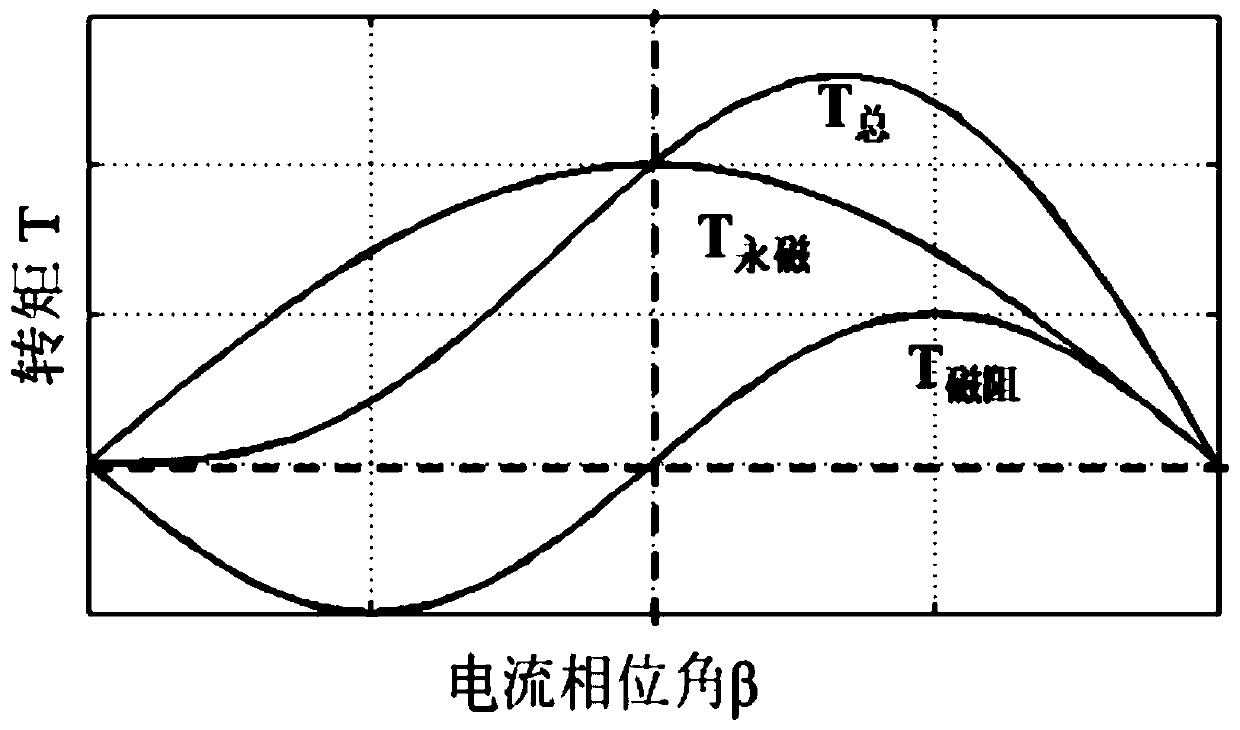

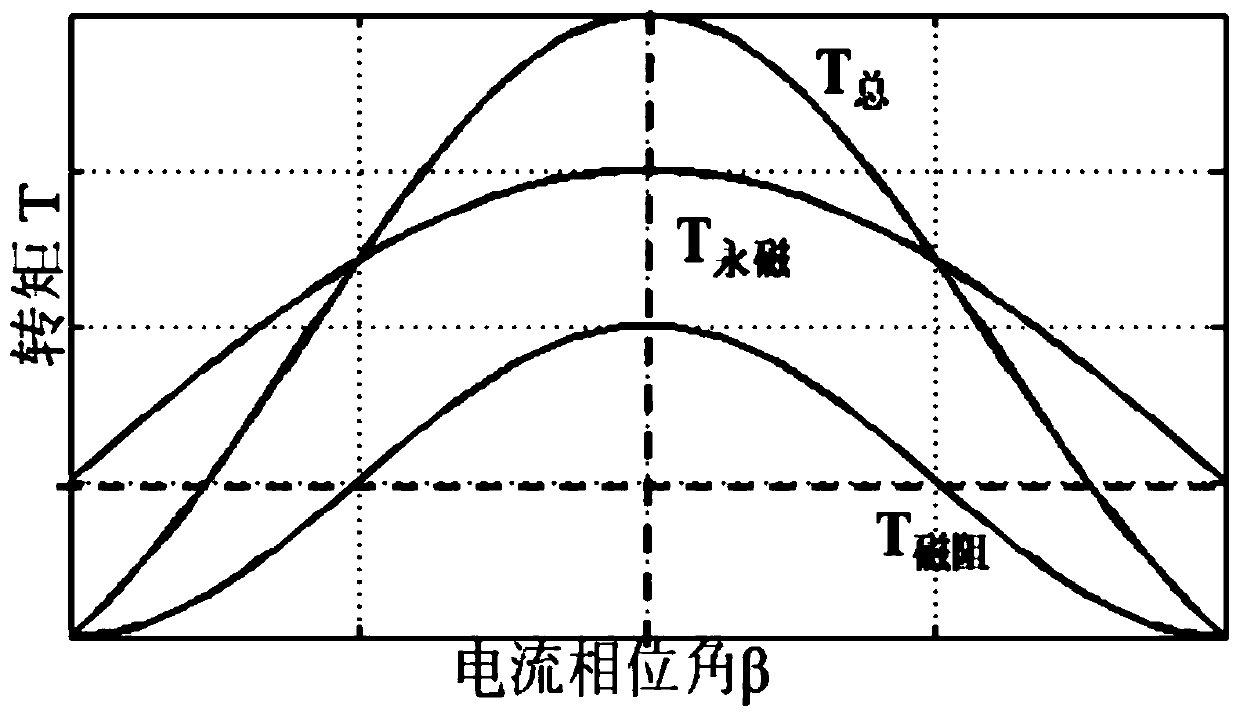

A permanent magnet synchronous and reluctance motor technology, applied in synchronous motors with stationary armatures and rotating magnets, electromechanical devices, magnetic circuits, etc. , with high-order harmonics and other problems, to achieve the effect of improving torque density and material utilization, improving electromagnetic torque, and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

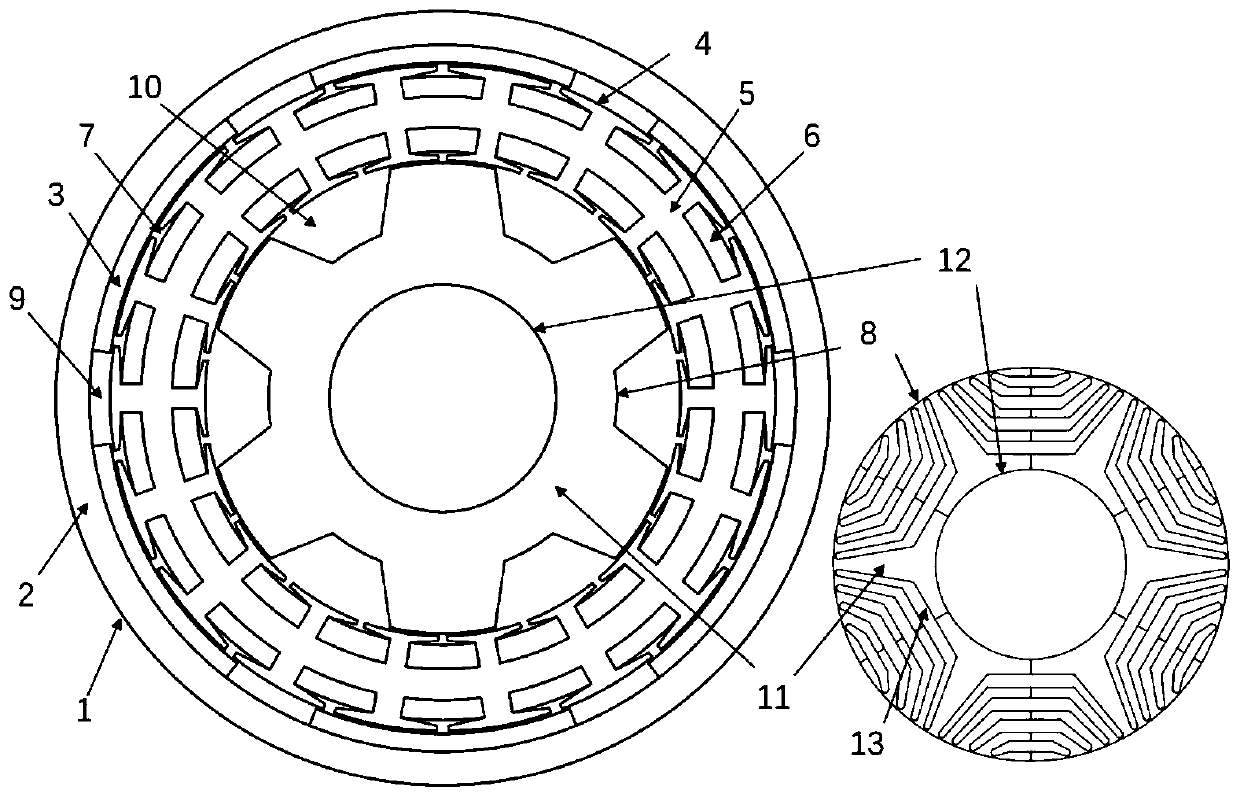

[0044] This embodiment discloses a dual-rotor permanent magnet synchronous reluctance motor, which is mainly composed of an outer rotor permanent magnet rotor 1 , an inner rotor reluctance rotor 8 and a stator 4 . Stator slots 7 are evenly opened inside and outside the stator 4 , and the stator 4 is located between the permanent magnet rotor 1 and the reluctance rotor 8 .

[0045]The stator 4 includes the stator core 5 and the stator winding 6. The inner and outer surfaces of the stator core 5 are slotted, and there are 36 stator slots 7 in total. to improve the working surface area and slot fill factor of the stator core.

[0046] The outer rotor permanent magnet rotor 1 includes a permanent magnet rotor core 2 and permanent magnets 3. The permanent magnets 3 have the same specifications and are evenly distributed along the circumferential direction. They are closely attached to the inner wall of the outer rotor core to form a surface-mounted permanent magnet rotor; Magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com