Method for improving saliency ratio of synchronous reluctance machine

A technology of synchronous reluctance motor and saliency ratio, which is applied in the control of generators, motor generators, electronically commutated motors, etc. It can solve the problems of occupying a lot of computer memory resources and increasing the workload of designers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

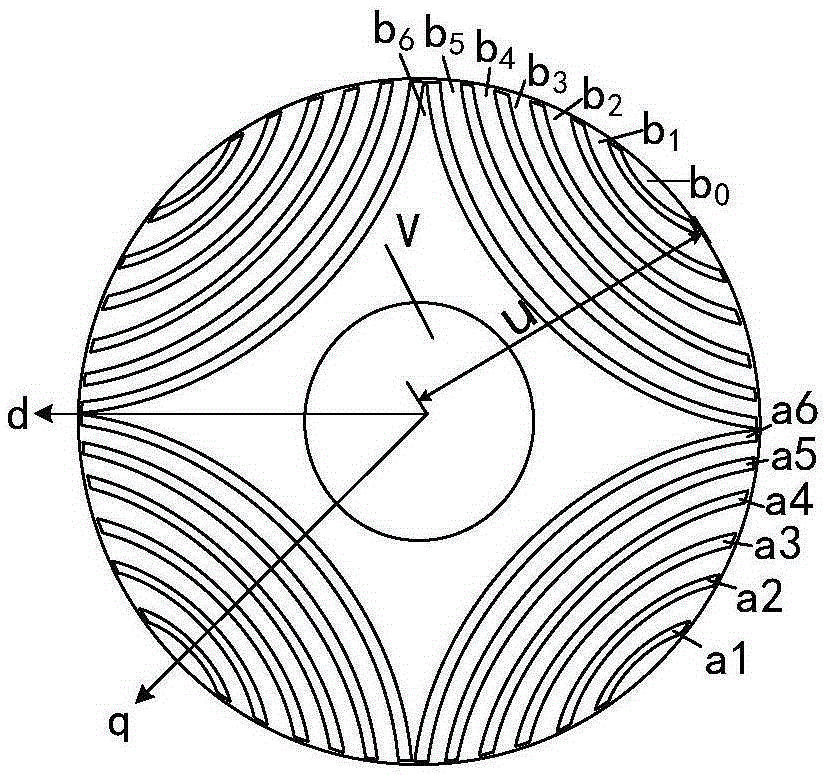

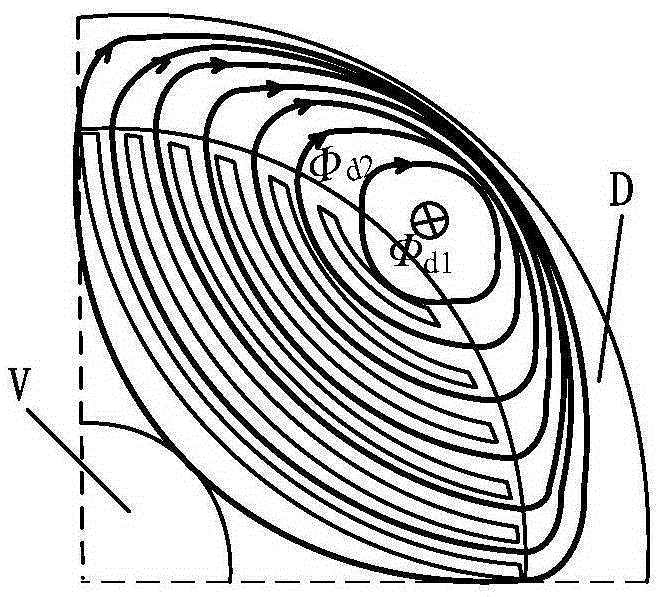

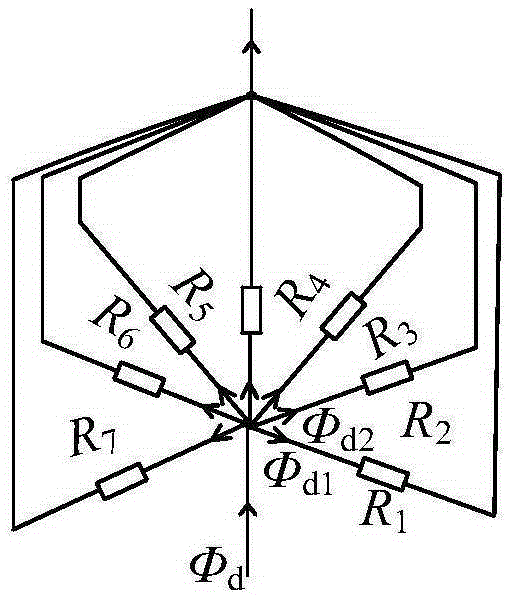

[0089] This embodiment takes TLR-SynRM as the implementation object. The rotor structure of TLR-SynRM is formed by alternate lamination of cold-rolled silicon steel sheets and insulating plastics (or electrical paper and other insulating materials). Cold-rolled silicon steel sheets are a kind of magnetically permeable material, and their physical properties are anisotropic, namely Along different directions of the crystal lattice, the periodicity and density of atomic arrangement are not the same, which leads to different physical and chemical properties of the crystal in different directions. Therefore, the magnetic field lines flowing through the d-axis magnetic circuit are determined to be paramagnetic. , and the lines of force flowing through the q-axis magnetic circuit behave as reverse magnetism.

[0090] The method steps for improving the TLR-SynRM saliency ratio of this embodiment are as follows:

[0091] Step 1: Determine the structural parameters of TLR-SynRM

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com