Multi-combination type permanent magnet motor rotor punching sheet and permanent magnet motor

A technology for rotor punching and permanent magnet motors, which is applied in the direction of magnetic circuit rotating parts, magnetic circuits, electrical components, etc., can solve the problems of increasing material control, purchasing cost and process complexity, failing to meet performance requirements and noise standards, shock Problems such as chip R&D and production cycle lengthening, to achieve the effect of increasing output torque, reducing moment of inertia, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

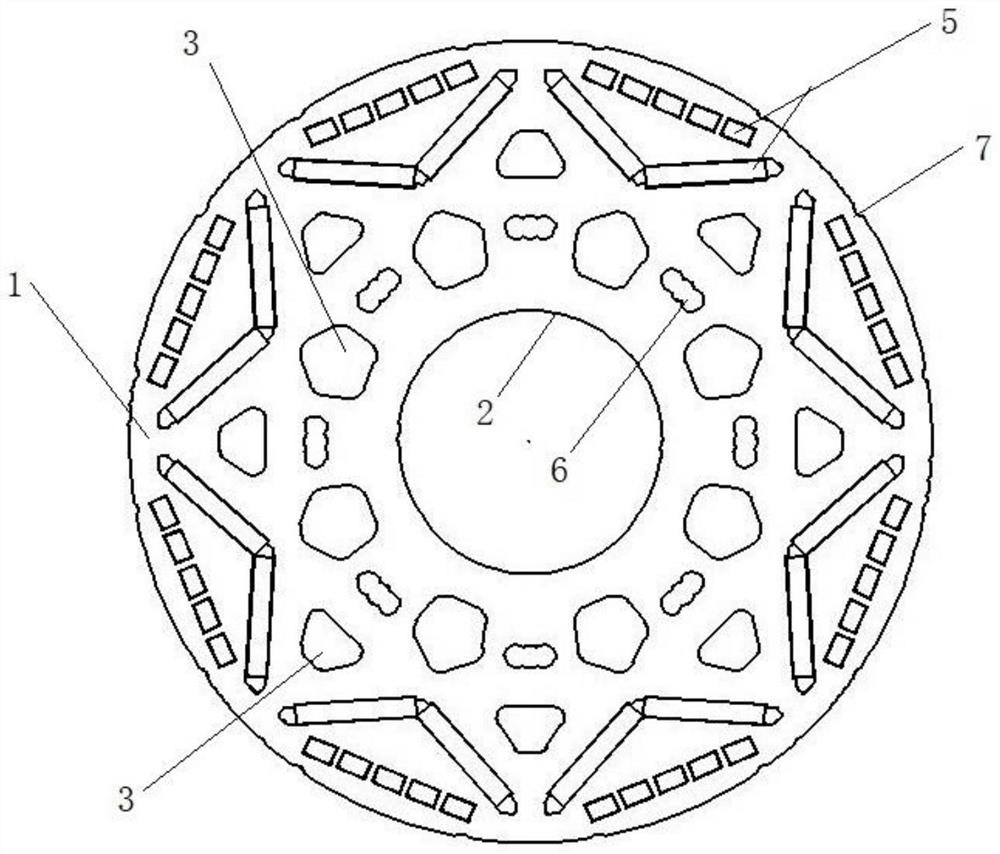

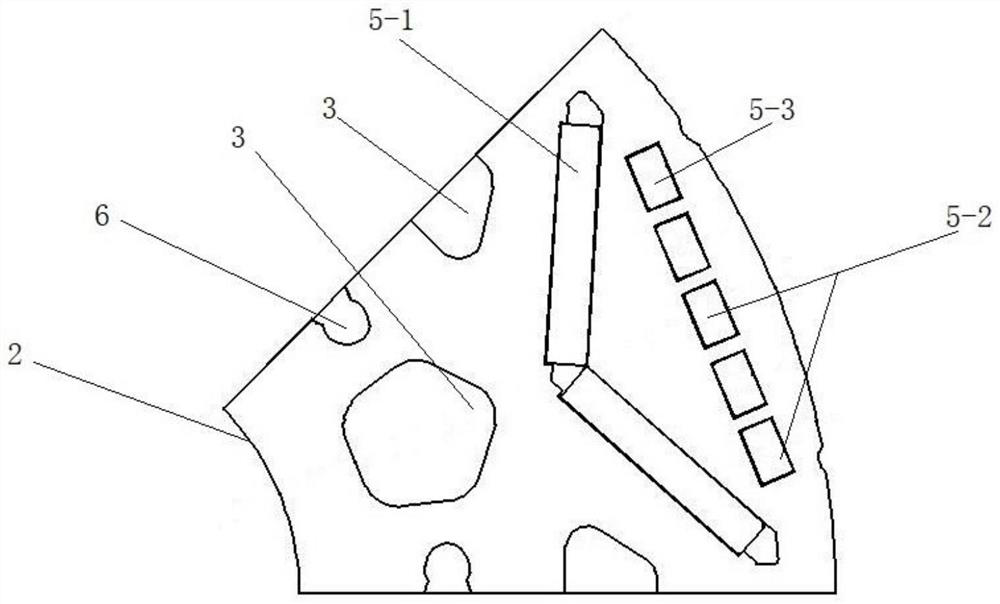

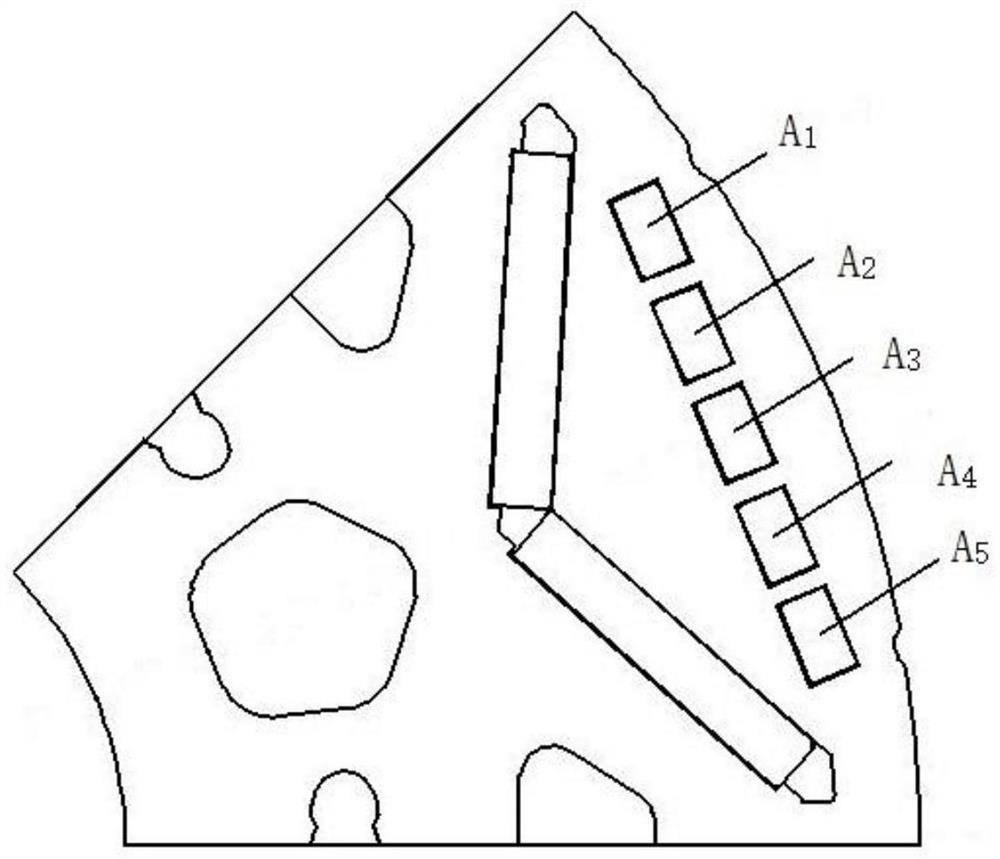

[0029] The present invention provides a multi-combinable permanent magnet motor rotor stamping, some of which are as follows Figure 1-3 As shown, it includes a circular rotor punching body 1, which is divided into a plurality of rotor poles 4 distributed in a circumferential array; the rotor punching body is provided with a shaft hole 2, a weight reduction hole 3 and a circumferential The inverted triangular magnetic steel slot 5 arranged circumferentially. The shaft hole is placed in the middle of the rotor punching body; the weight-reducing holes adopt one or more shapes of holes evenly distributed in the circumferential direction of the rotor punching body to reduce the moment of inertia of the motor and the weight of the whole machine. A set of inverted triangular magnetic steel grooves are arranged on a single rotor pole, and the inverted triangular magnetic steel gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com