Roller radial adjusting mechanism of cross beam type four-roller profile rolling mill

A technology of adjusting mechanism and cross beam, which is applied in the direction of metal rolling mill stand, metal rolling stand, metal rolling, etc., can solve the problems of unstable operation of the mechanism, increase of investment cost, vibration, etc., and achieve compact structure and high efficiency Productivity, effect of reducing roll change work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

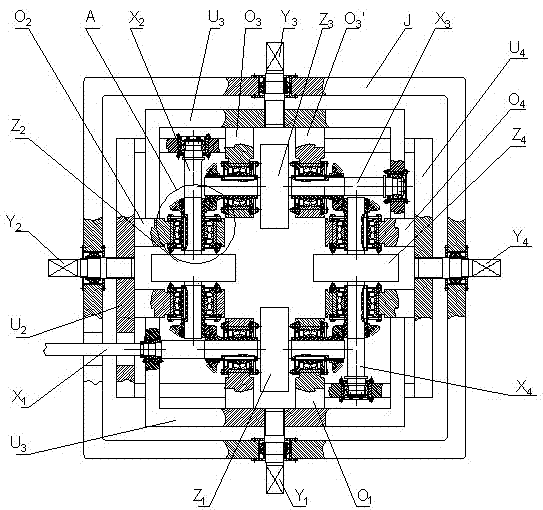

[0029] by figure 1 The single-axis centralized transmission shown is taken as an example, and the roll is adjusted radially. Turn the pressing screw Y that cannot move axially 3 , driving the cross beam U 3 Move down, push the left and right bearing seats O 3 , O 3 ' and mandrel X 3 move down, that is done on the roll Z 3 radial adjustment. MandrelX 3 The downward movement will inevitably drive the bevel gears at the left and right ends to move downward, such as Figure 5 As shown, the meshing bevel gear 17 is connected to the sleeve 22 through the key 19, and the sleeve 22 is connected to the spindle X through the feather key 21 2 connection, the bevel gear transmission can be realized to follow the sleeve 22 to move down, and at the same time follow the cross beam U 3 What moves down is that the legs on the left and right sides respectively push the bearing seat O 2 , O 4 Move down, bearing seat O 2 And the bearing 24 is installed on the sleeve 22, and the sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com