Detection apparatus of pre-tightening force of angular contact bearing and detection method thereof

An angular contact bearing and detection device technology, applied in the direction of torque/torsional force measurement during tightening, can solve the problems of increasing manufacturing costs, inability to know the preload force value, and accumulating errors, etc., to reduce processing and manufacturing costs, Increased service life and improved consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

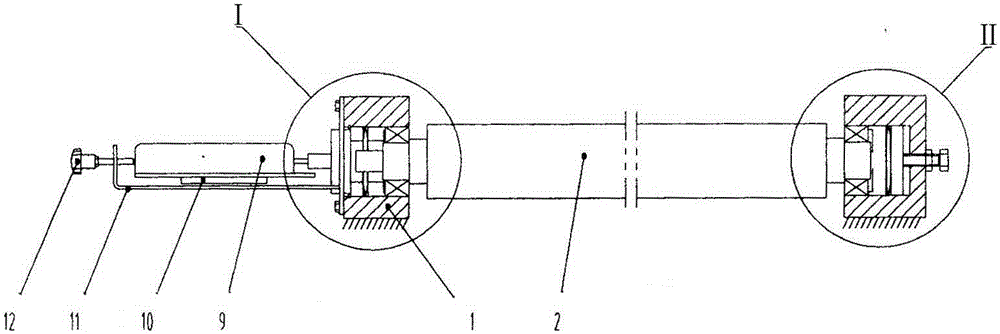

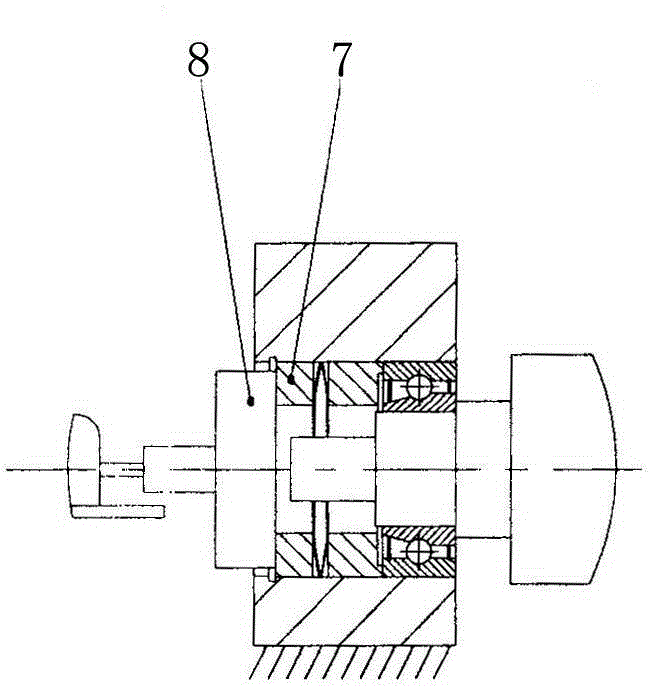

[0025] Such as figure 2 , 3 , 4, the angular contact bearing pretightening force detection device of the present invention comprises a dynamometer support 11, and the dynamometer 9 installed on the dynamometer support 11 through a linear slide rail 10 is screwed on the The push rod 12 for driving the force gauge 9 to move axially along the linear slide rail 10 at the rear end of the force gauge bracket 11, and the compression sleeve 8 arranged at the front end of the force gauge 9; The outside diameter is smaller than the inside diameter of the corresponding housing.

[0026] The detection method of angular contact bearing preload of the present invention adopts following steps to realize:

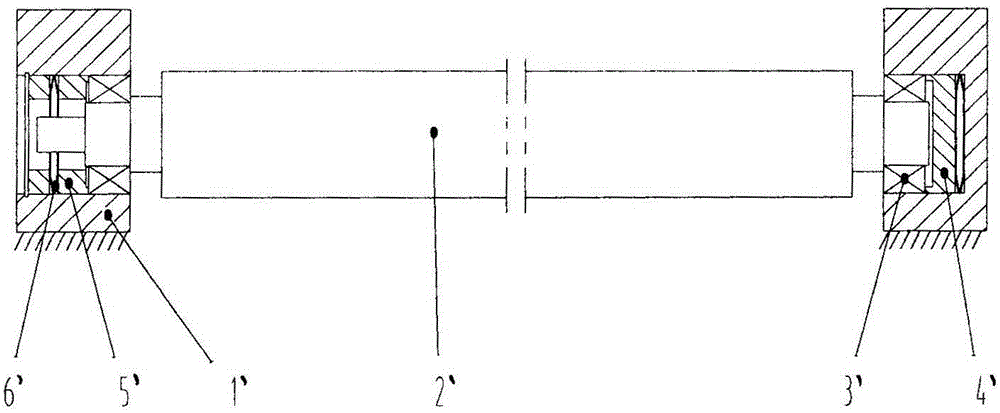

[0027] a. First, install the left and right ends of the shaft 2 through the left and right angular contact bearings 3 in the left and right bearing seats on the frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com