Assembly test vehicle of airplane main landing gear

A landing gear and test vehicle technology, which is used in aircraft component testing, aircraft parts, ground installations, etc., can solve the problems that the degree of freedom cannot be manually adjusted flexibly and quickly, the entire mechanism cannot be transported, and the degree of freedom cannot be quantitatively adjusted. The effect of easy alignment, high degree of freedom, and improved assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

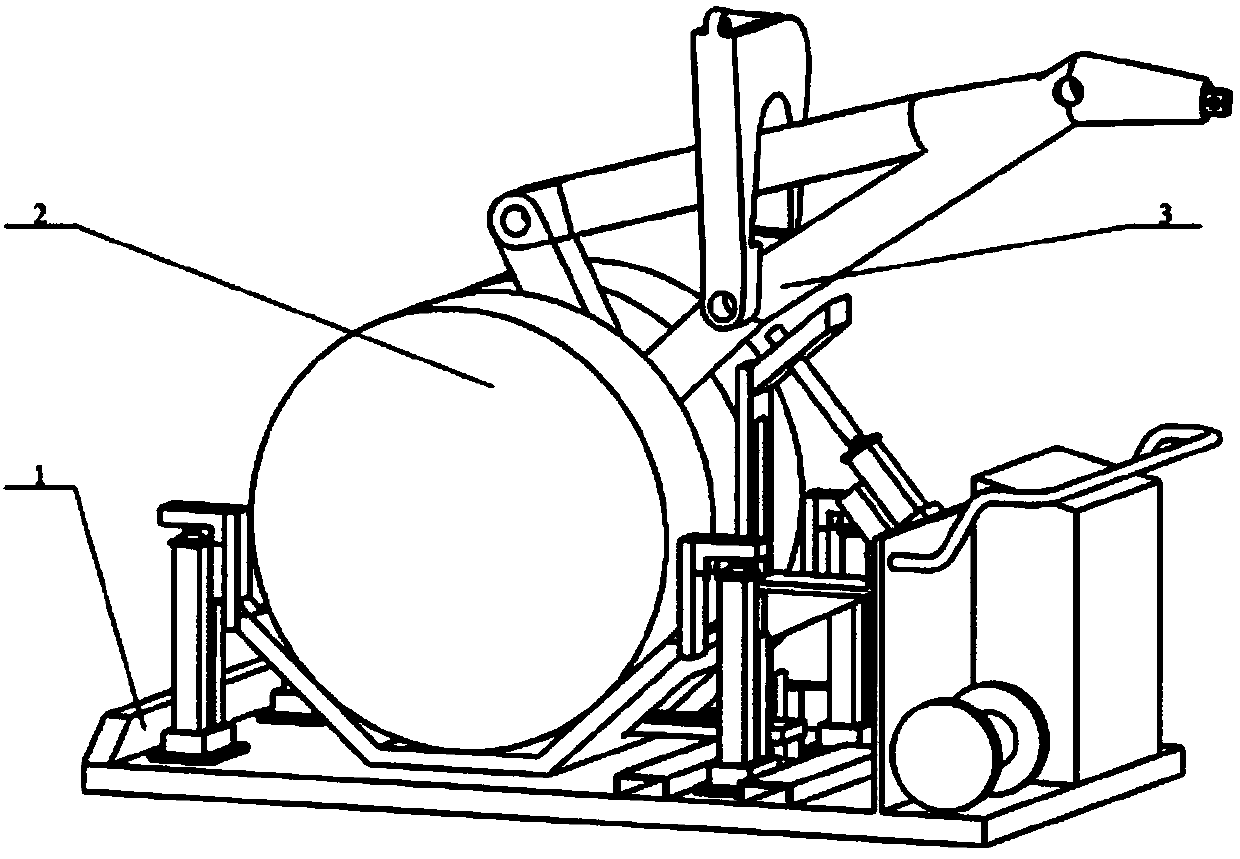

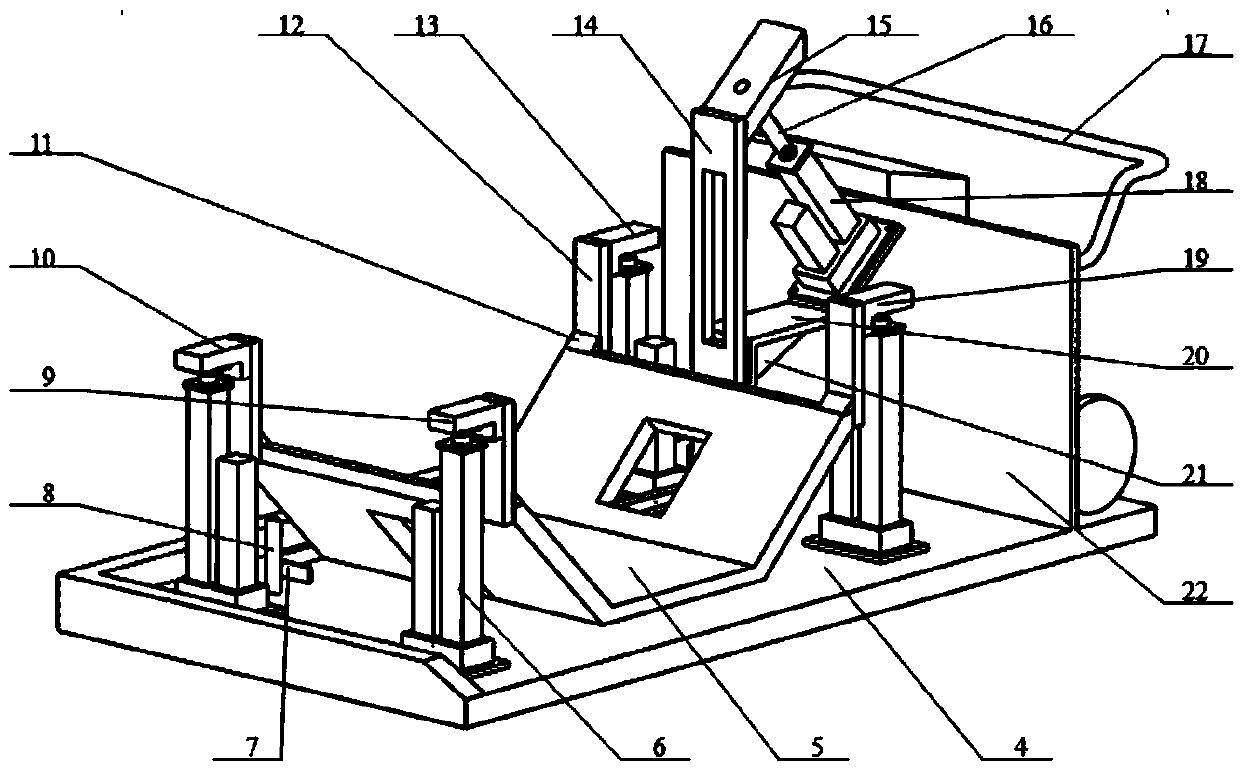

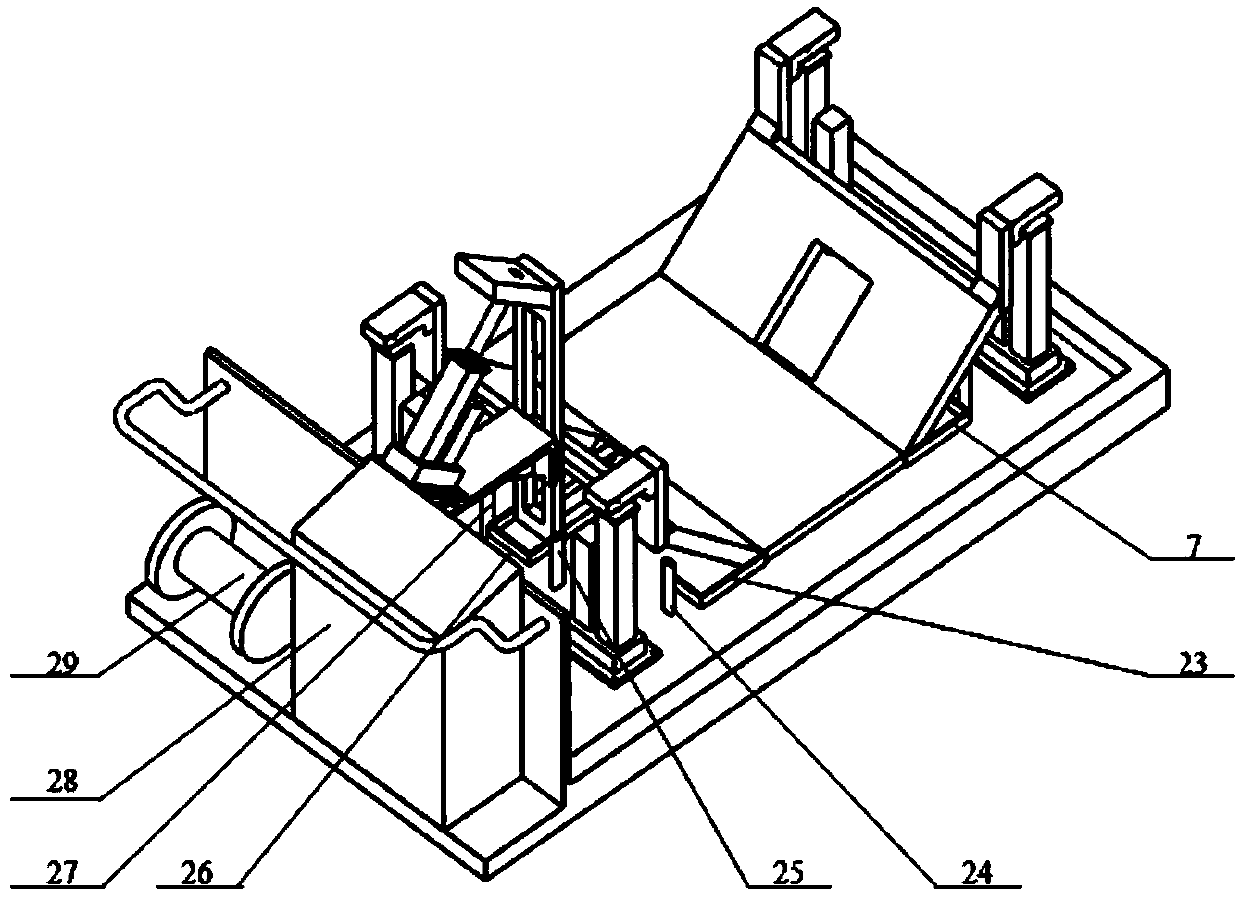

[0023] This embodiment is a test vehicle for assembling the main landing gear of an aircraft.

[0024] refer to Figure 1-Figure 11 , the aircraft main landing gear assembly test vehicle of the present invention uses an air-floating platform to realize the movement of the main landing gear along the X-axis and the Y-axis and the rotation around the Z-axis; four vertical servo electric cylinders are used to realize the movement of the main landing gear along the Z-axis. The movement and rotation around the X-axis and Y-axis; a tilting servo electric cylinder is used to realize the rotation of the pillar of the main landing gear along the wheel axis. The horizontal radial direction of the wheel shaft is the X-axis direction, the axial direction of the wheel shaft is the Y-axis direction, the vertical direction is the Z-axis direction, and the rotation around the wheel shaft is pitching. The docking vehicle should be able to easily move and turn in the factory building, transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com