Loading and unloading assisting device

A power-assisting device, a pair of technology, applied in the directions of loading/unloading, manual conveying device, transportation and packaging, etc., can solve the problems of high price, different spring elasticity, poor versatility, etc., and achieve the effect of saving time and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

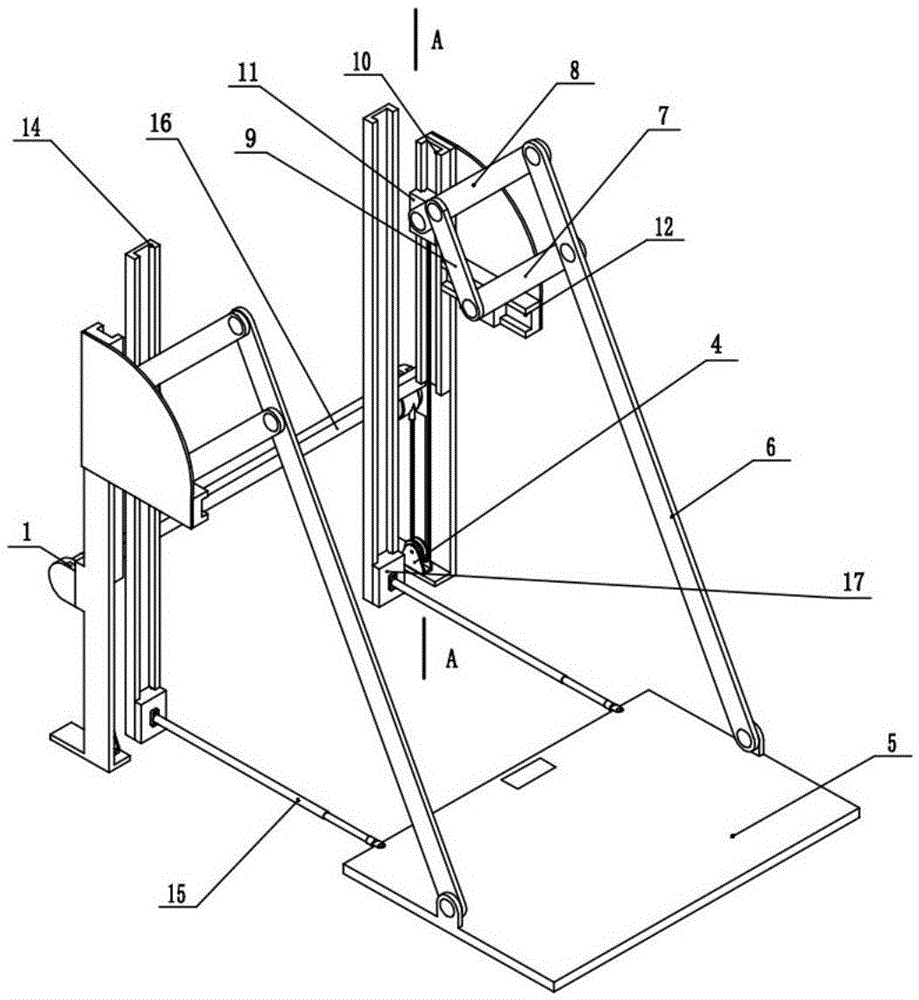

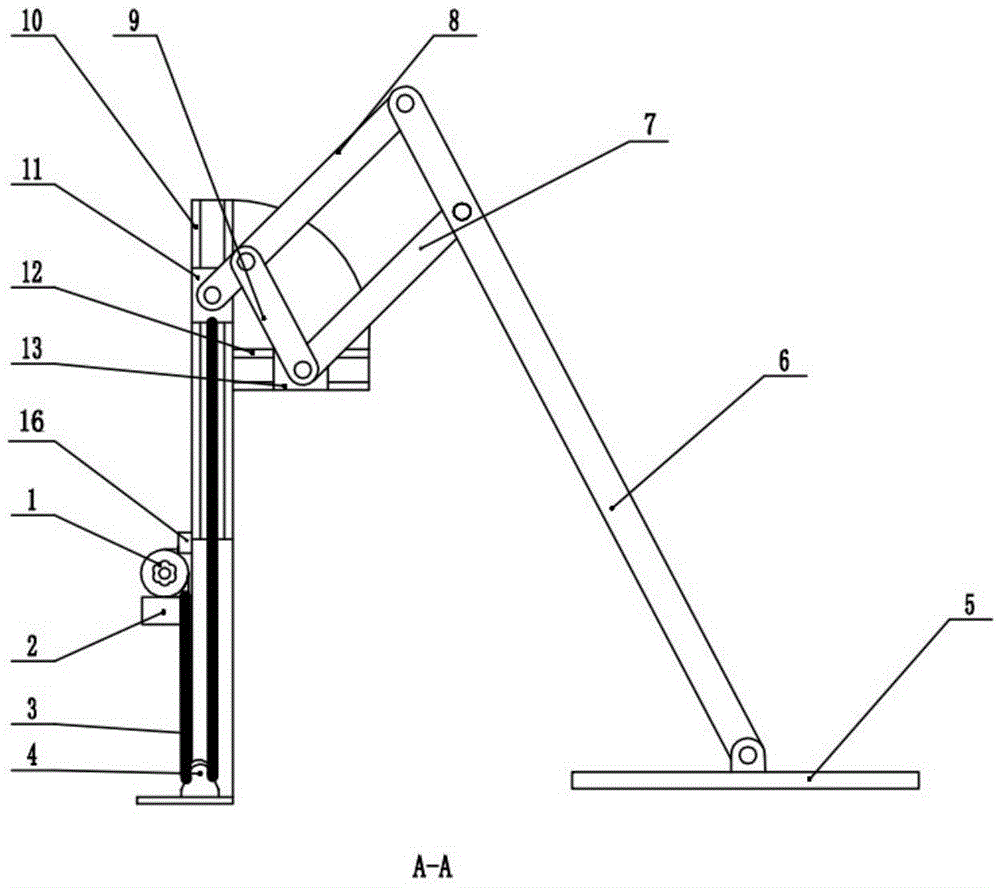

[0018] A loading and unloading assisting device, including a frame and a link mechanism, the main features are: the frame is an H-shaped structure, the left and right ends of the frame beam 16 are provided with floor columns 10, and the upper half of the floor column 10 is provided with There is a vertical chute 1 cooperating with the first slider 11 in the vertical direction, the lower end is provided with a pulley 4, the middle side of the vertical chute 1 is provided with a horizontal chute 12, and the horizontal chute 12 is provided with a second horizontal chute matched with it. Slide block 13; frame crossbeam 16 inner side is provided with a pair of column 14 with vertical chute 2, and the 3rd slide block 17 that cooperates with vertical chute 2 is fixedly connected with gas spring 15; The rod mechanism is arranged in parallel, and their upper active points are respectively located in the vertical chute 1 and the horizontal chute 12 of the landing column 10, and one end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com