Experimental method for performing air cooling and heating process on heating wire rod and air cooling device

The technology of an air-cooling device and experimental method, which is applied in the field of air-cooling of heat treatment, can solve the problems that the improvement scheme and parameters of the wire rod process cannot be improved, and the experimental method of heating the wire rod is not ideal, so as to avoid grain coarsening, simple structure, Lightweight and compact device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings, but it is not intended to limit the present invention.

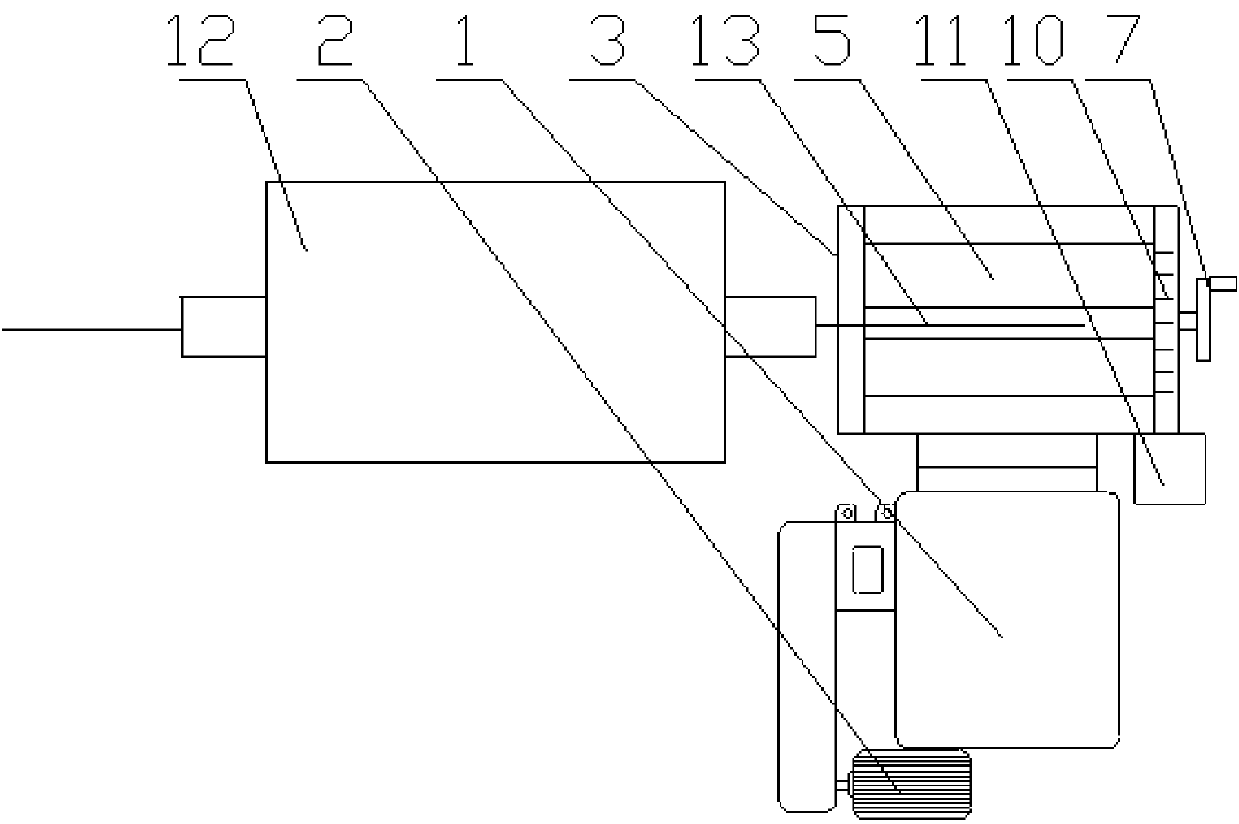

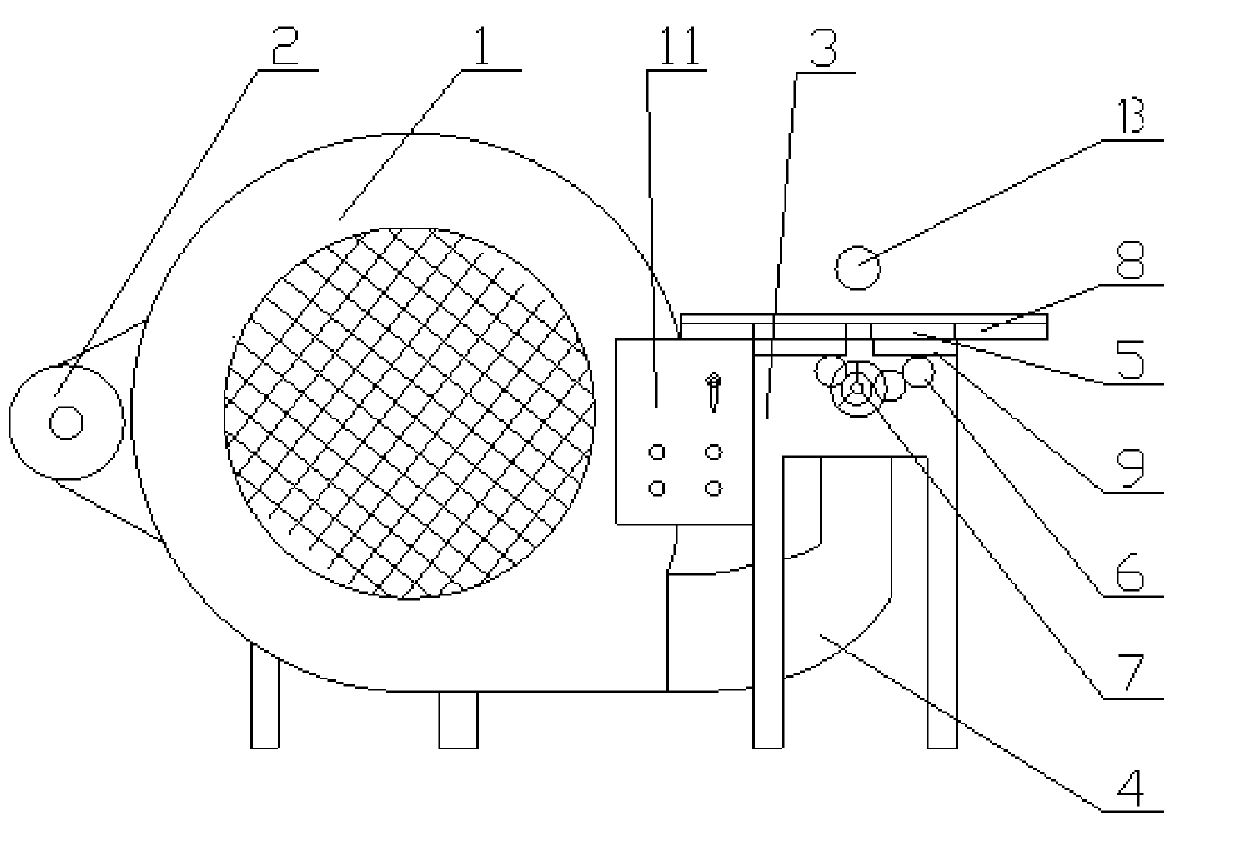

[0015] Embodiments of the present invention: when carrying out the air-cooling heat treatment experiment to heating wire rod in laboratory, adopt method of the present invention to implement, comprise adopting existing tubular heating furnace 12 to heat experimental wire rod 13, in will After the wire rod 13 is heated to a specified temperature by the tubular heating furnace 12 (generally, it can be heated to 850-900°C, and it can also be heated according to the actual temperature), and then the heating tube of the tubular heating furnace 12 will Reach the wire rod 13 output of temperature, set the air cooling device that a wind speed and air volume can be adjusted at the outlet of the heating pipe of outputting wire rod 13, make the wire rod 13 of heating pipe output pass through the air outlet of air cooling devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com