Automatic detection method for brake shoe borer loss fault of railway wagon

A railway freight car, automatic detection technology, applied in the field of image processing, can solve the problems of brake shoe brazing loss, time-consuming and laborious maintenance costs, etc., and achieve the effect of reducing the possibility of false detection and reducing the amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but the scope of protection of the present invention is not limited to the following embodiments.

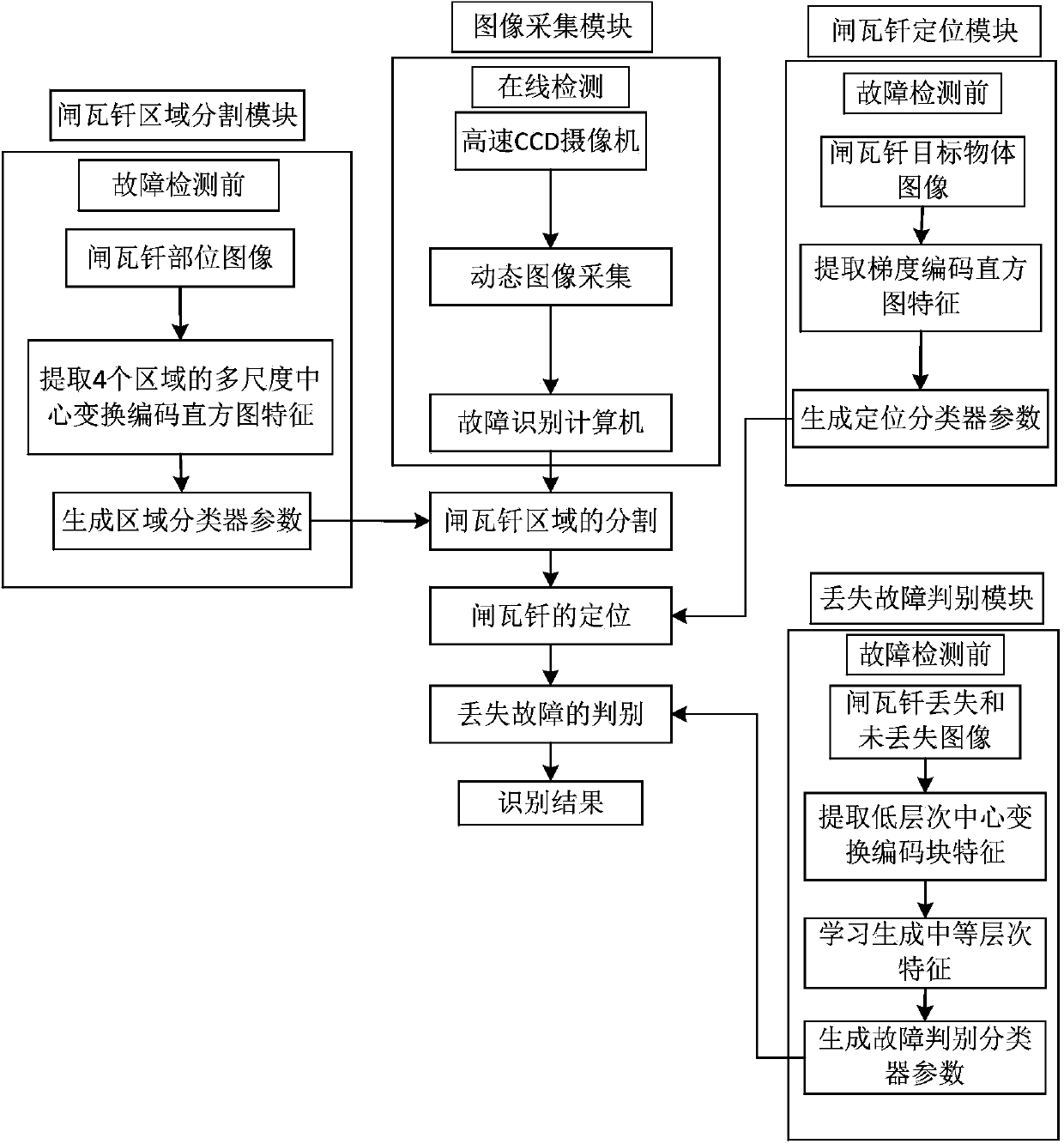

[0022] Such as figure 1 As shown, this embodiment processes the brake shoe brazing part image (1400×1024 pixels) collected on the railway site. These images have significant lighting changes, and the background and brake shoe shapes are complex. This embodiment includes the following steps:

[0023] In the first step, since the relative position between the high-speed camera and the brake shoe brazing part remains basically unchanged when shooting, the brake shoe brazing basically appears in a quarter of the image of the brake shoe brazing part. Therefore, in the actual detection process, a complete brake shoe brazing image is first divided into four regions (700×512 pixels) of equal size, and these four regions are detected s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com