High-temperature anhydrous gypsum pavement brick and kerb and preparation method thereof

An anhydrite and pavement brick technology, applied in the field of road engineering, can solve the problems of reducing curb protection effect, affecting road aesthetics, natural resource consumption, etc., achieving easy industrial flow operation, shortening production cycle time, and increasing production capacity effect of quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

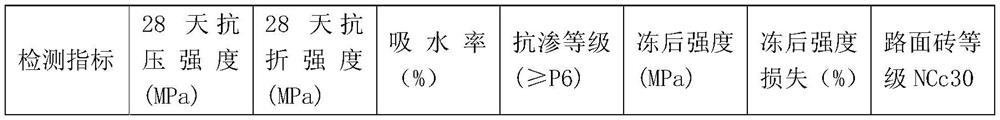

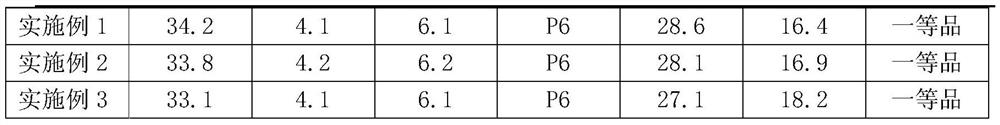

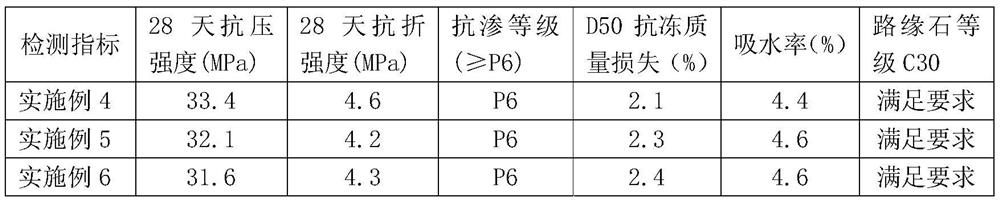

Examples

Embodiment 1

[0026]A high-temperature hydrated plaster pavement brick, including the following materials: High-temperature water water gypsum 70kg, silicate cement 10kg, silicon powder 5 kg, initiator 0.14 kg, water 25 kg, 0.7 kg of water reduction agent.

[0027]Among them, high-temperature anhydrous gypsum is anhydrous gypsum prepared by high temperature by dihydrate gypsum at high temperature of 600 to 900 ° C; silicate cement is P.O42.5 ordinary silicate cement; Silicon powder contains silicon ≥ 90%; the initiator is 30 to 50% sulfate, 30 to 50% sulfate, 10 to 30% ammonium salts, mixed into a mixture of 80 mesh, mixed by weight of 30 ~ 50% ammonium salide, mixed to 80 megadownload Carboxylic acid reduction agent; fibers are polypropylene fibers; water meets water requirements for concrete mixing.

[0028]Preparation method of the high temperature anhydrous plaster pavement brick:

[0029](1) Pour the high temperature anhydrous gypsum, silicate cement, silica powder, and fibers into the stirring tank,...

Embodiment 2

[0035]A high-temperature water plaster pavement brick, including the following materials: 80kg, fly ash 9kg, silicon powder 7kg, initiator 0.16 kg, water 25 kg, fiber 0.16 kg, dispersant 1.6kg.

[0036]Among them, high-temperature aqueous gypsum is anhydrous gypsum prepared by heating water from water by using a dihydrate gypsum at a calcination temperature of 600 to 900 ° C; fly ash is a grade II fly ash; silicon powder contains silicon 90%; the initiator is a mixture of 30 to 50% sulfate, 30 to 50% sulfate, 10 to 30% ammonium salts by weight, and mixed into a mixture of 80 megadownloadpicies; the dispersant is a commercially available polyvinyl alcohol. The adhesive is a commercially available polyether compound; the fibers are polypropylene; water meets the water requirements for concrete mixing.

[0037]Preparation method of the high temperature anhydrous plaster pavement brick:

[0038](1) Pour high temperature anhydrous gypsum, fly ash, silica powder, fiber into the stirring tank, low ...

Embodiment 3

[0044]A high-temperature water plaster pavement brick, including the following materials: high temperature anhydrous gypsum 60kg, milling steel slag powder 10kg, silicon powder 5kg, initiator 0.2 kg, fiber, 4 kg of fiber, 4 kg.

[0045]Among them, high-temperature water water gypsum is anhydrous gypsum prepared by high temperature by high temperature of dihydrate plaster at a calcination temperature of 600 to 900 ° C; silicon powder contains silicon is ≥90%; grinding steel slag powder is steelmaking Slag grinding steel slag powder; initiator is a mixture of 30 to 50% sulfate, 30 to 50% sulfate, 10 to 30% ammonium salts, mixed by weight of 30 to 50% ammonium sulfate, and mixed into 80 mesh; fiber is polypropylene; viscomela For the market, the polyether compound is used; water meets the concrete mixed water requirements.

[0046]Preparation method of the high temperature anhydrous plaster pavement brick:

[0047](1) Pour high temperature anhydrous gypsum, grinding steel slag powder, silica po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com