Patents

Literature

52results about How to "Good resistance to salt spray corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Molybdate passivating liquid for continuous hot-dipping galvanizing steel plate

ActiveCN101429661AGood resistance to salt spray corrosionMetallic material coating processesMolybdatePhosphoric acid

The invention relates to a molybdate passivation liquid for a continuous hot dip galvanized steel sheet, and belongs to the technical field of metal surface treatment and corrosion prevention. The molybdate passivation liquid comprises the following components according to the proportion for 1L of water: 30 to 50g / L of molybdate, 3 to 10g / L of fluozirconate, 3 to 15g / L of HEOP, 5 to 25g / L of citric acid, 10 to 30g / L of oxydol, 10 to 30g / L of acidic silicasol, and 15 to 25g / L of phosphoric acid. The molybdate passivation liquid has the advantages that as the recipe does not contain chrome, the molybdate passivation liquid has no impact on human bodies and environment; the salt fog resistance of the galvanized steel sheet which has the galvanizing coating passivated by the molybdate passivation liquid is better than that of the steel sheet passivated by chromates.

Owner:CHANGSHU HUAYE STEEL STRIP

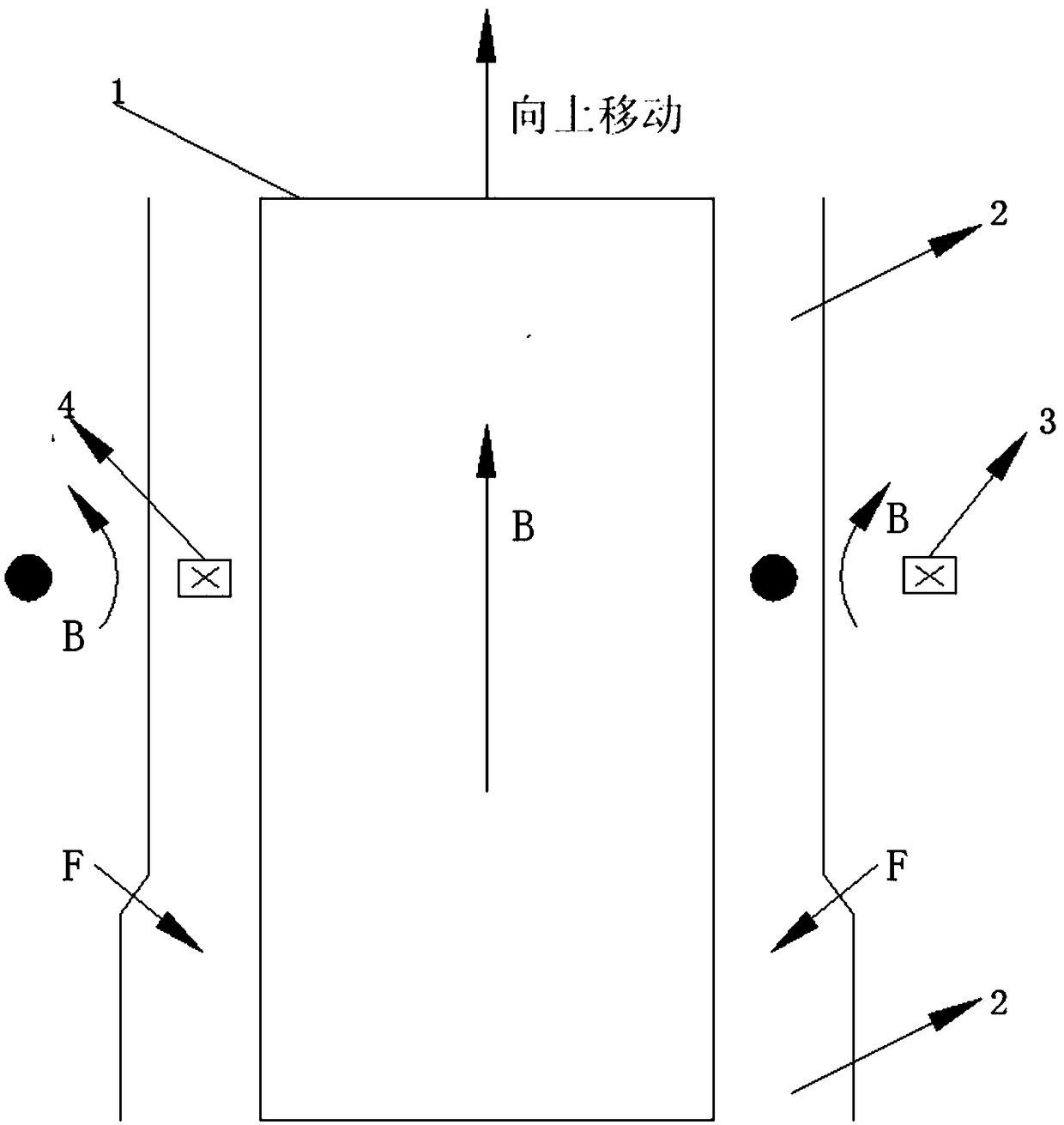

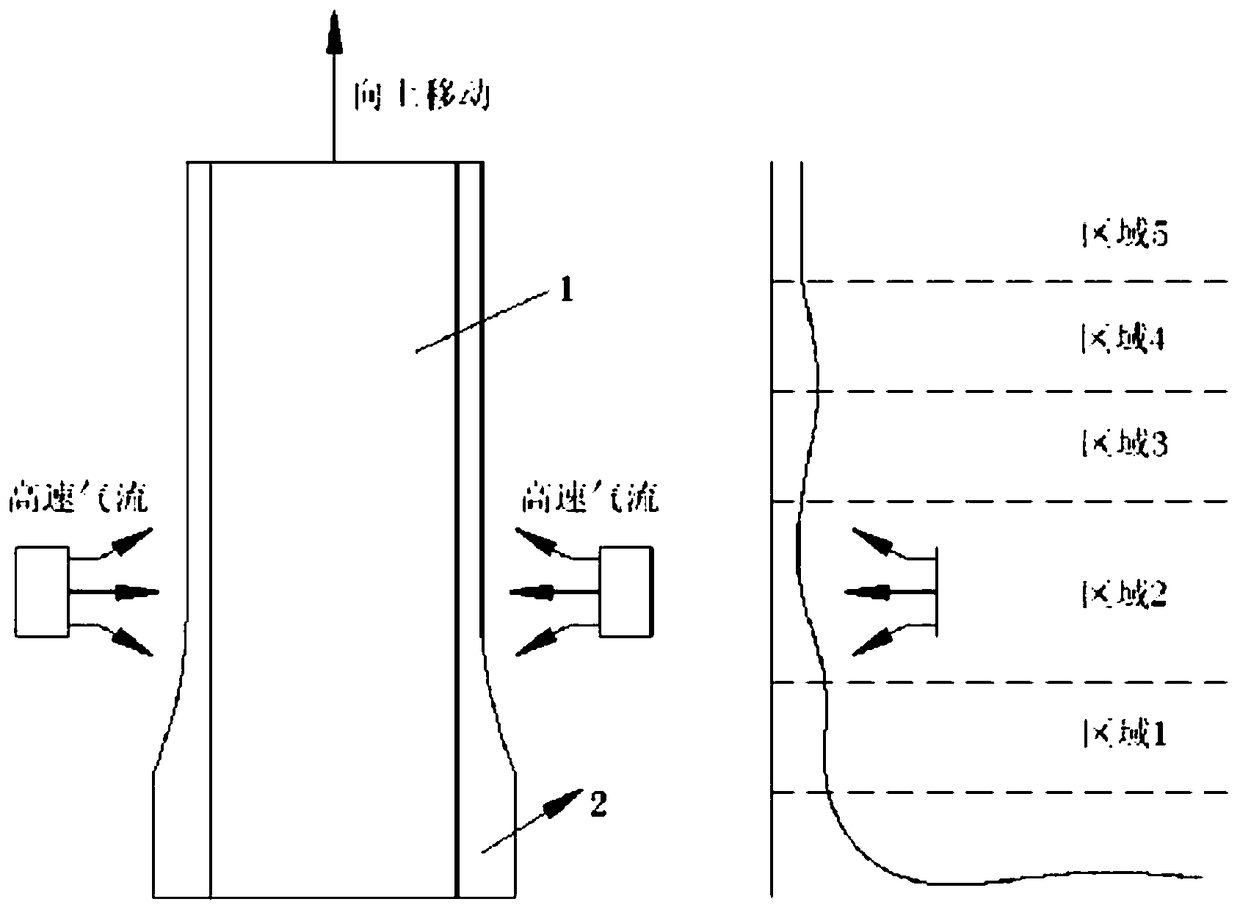

Preparation method for magnetron sputtering TiMo film on titanium alloy surface

ActiveCN102115872AThickness is easy to controlNo sheddingVacuum evaporation coatingSputtering coatingSputteringTitanium alloy

The invention discloses a preparation method for magnetron sputtering a TiMo film on a titanium alloy surface, which is characterized in that the preparation method comprises the steps of pre-sputtering treatment, substrate installation, sputtering and film forming, etc. Compared with the prior art, the invention realizes the purpose of preparing a Ti-Mo film on a titanium alloy surface by the magnetron sputtering process; a film with a thickness of 1-50 microns can be obtained by controlling the process conditions, and the film has good compactness, good bonding force with the substrate, anda controllable thickness; and a film with a uniform thickness can be obtained on a large-area substrate. The coating prepared by the invention has excellent resistance to salt spray corrosion even ata temperature of 600 DEG C, and the used preparation method can produce high-quality products with the guarantee of batch production.

Owner:沈阳天贺新材料开发有限公司

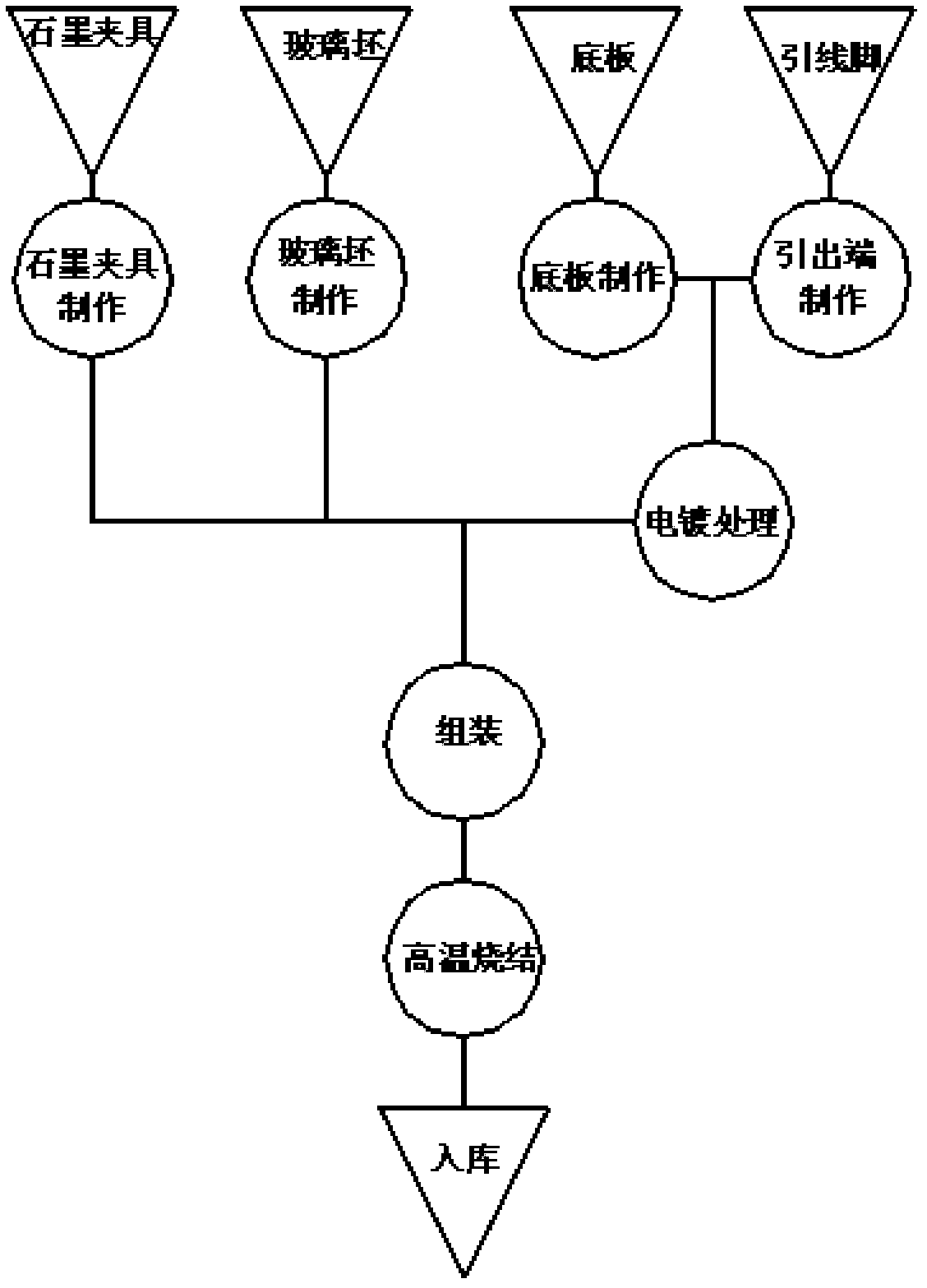

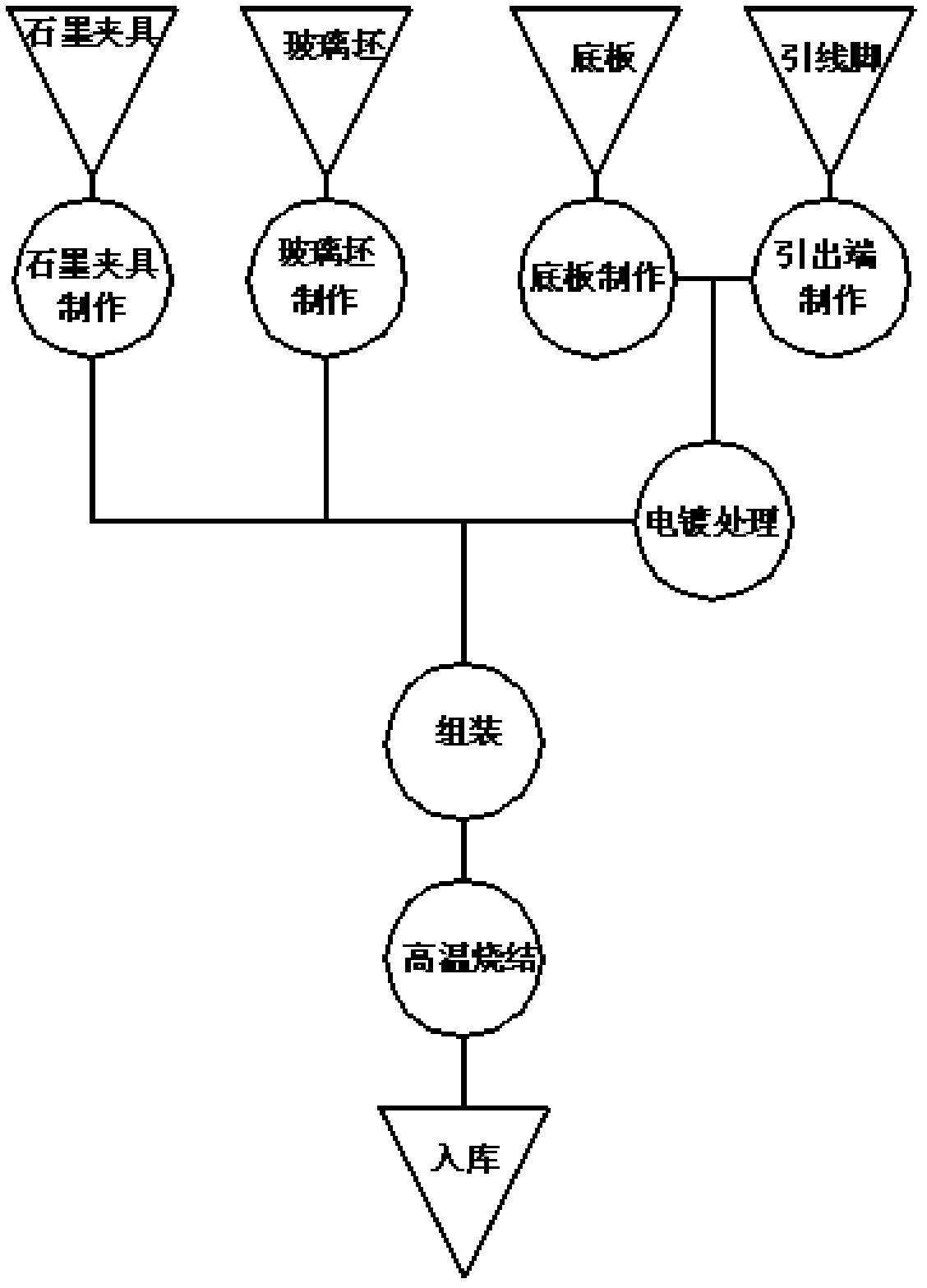

Metal pretreatment method for metal-glass sealing technology

The invention discloses a metal pre-treatment method of the metal-glass sealing technology. The method is to first conduct surface electroplating treatment on the Kovar alloy to be glass sealed, and then electroplate the Kovar gold lead wire and The bottom plate and the glass blank are mounted together, and the glass is melted and sealed at high temperature. In the present invention, the electroplating process is used to replace the traditional pre-oxidation process in the pre-treatment of the metal. The sealing parts obtained in this way are not only beautiful in appearance, but also have better air tightness, less air bubbles on the surface and inside of the glass insulator, and high bonding strength between the glass and the lead wire. And the number of bending is more, the bonding strength is higher than that of the traditional pre-oxidized sealing parts, and the product consistency is better. The components after electroplating have strong salt spray corrosion resistance, which meets the requirements of use and can be widely used in metal packaging, relays , connectors, solar vacuum heat collectors and other fields.

Owner:贵州振华群英电器有限公司(国营第八九一厂)

Construction process of high-durability epoxy floor

InactiveCN108385933AImprove wear resistanceImprove skid resistanceAnti-corrosive paintsFlooring insulationsEpoxyGlass fiber

The invention specifically relates to the field of floors and particularly relates to a construction process of a high-durability epoxy floor. The construction process of the high-durability epoxy floor at least comprises the following steps: (1) treating a base layer; (2) laying a primer layer; (3) laying a first glass fiber layer; (4) laying a first epoxy mortar layer; (5) laying a second glassfiber layer; (6) laying a second epoxy mortar layer; (7) laying a third glass fiber layer; (8) laying a finishing coating layer; (9) cleaning and drying the finishing coating layer, so as to obtain the high-durability epoxy floor.

Owner:青岛舜捷通生物科技有限公司

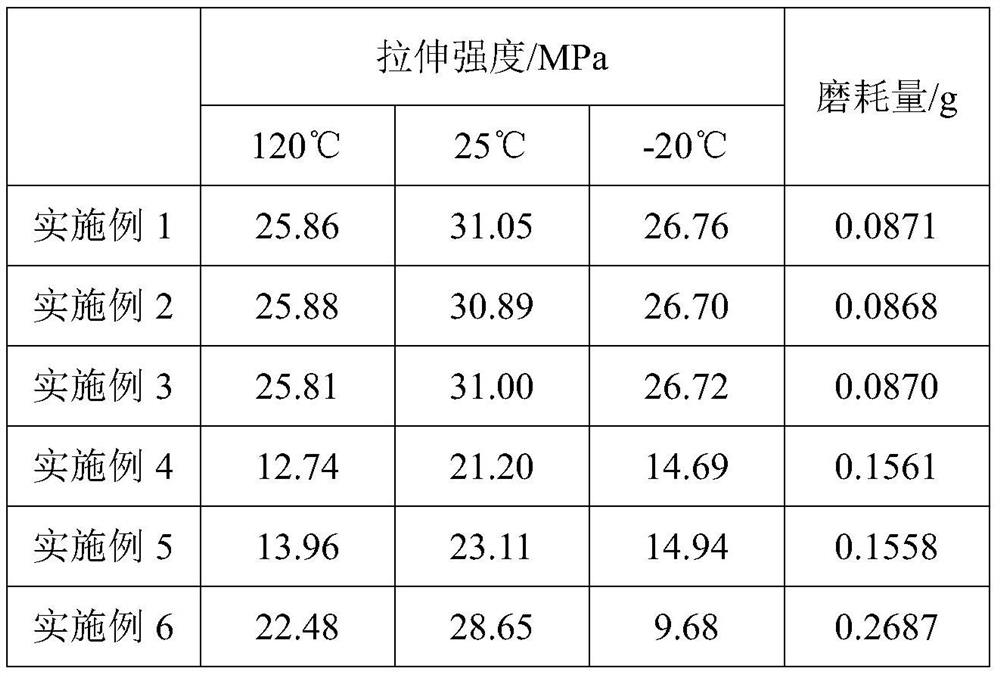

High-strength wear-resistant modified natural rubber and preparation method thereof

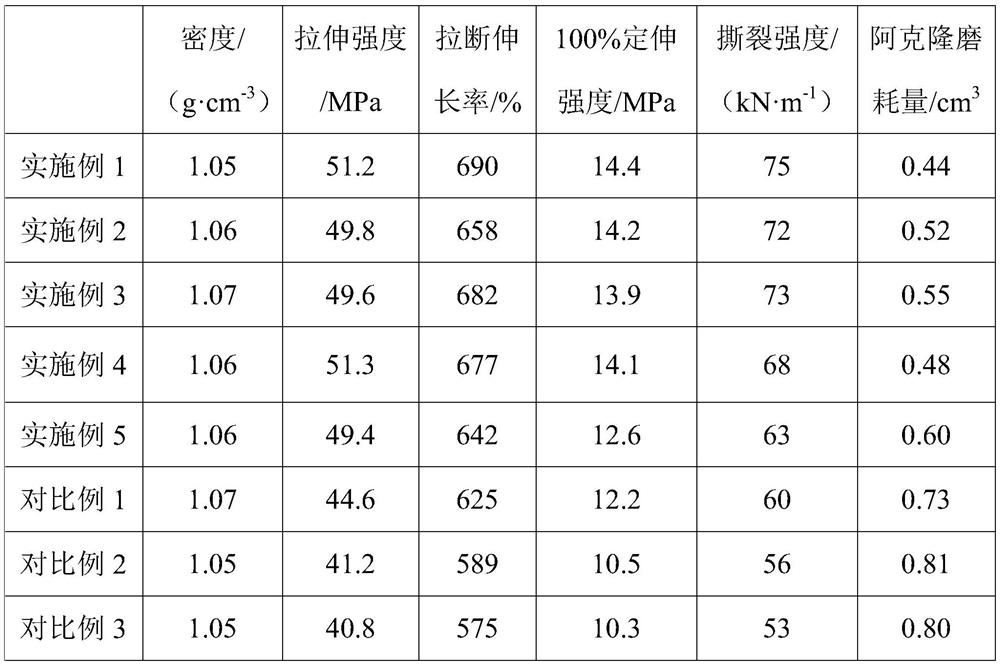

The invention discloses a high-strength wear-resistant modified natural rubber. The rubber comprises, by weight, 60-70 parts of natural rubber, 15-20 parts of ethylene propylene diene monomer, 6-9 parts of butadiene rubber, 8-10 parts of a reinforcing agent, 2.5-3.5 parts of epoxy resin, 2-3 parts of a silane coupling agent, 1-2 parts of an accelerant, 1-2 parts of an anti-aging agent, 0.3-0.5 part of an emulsifier and 4.5-5 parts of a plasticizer. The rubber shows good mechanical strength at a high temperature and a low temperature, and also has excellent wear resistance and good sunlight andultraviolet aging resistance and weather resistance. In addition, the rubber also has good salt spray corrosion resistance, excellent flame retardance, good comprehensive performances and long service life, and can meet the use requirements of various fields, such as aviation products, windscreen wipers for automobiles, sealing strips, sealing rings and the like.

Owner:贵州科润密封科技有限公司

High-strength multi-element zinc base alloy coated steel wire for bridge cable, and hot-dipping technology thereof

ActiveCN108707852AGood resistance to salt spray corrosionHigh strengthHot-dipping/immersion processesRare earthTwo step

The invention relates to a high-strength multi-element zinc base alloy coated steel wire for a bridge cable. The steel wire is characterized in that hypereutectoid steel wire rods with the carbon content of 0.82% above are drawn to form bright steel wires with the strength of 2000 MPa above, and then the bright steel wires are hot-galvanized to form hot-galvanized aluminum alloy steel wires; the coating comprises Zn-Al alloy, and one or more of trace rare earth, trace nickel elements and magnesium elements are added selectively. The hot-dipping technology comprises two steps of hot dipping ofzinc base alloy solutions and hot galvanizing of aluminum alloy solutions, and one or more of the trace rare earth, the trace nickel elements and trace aluminum elements are added to the hot-dip zincbase alloy solutions. According to the steel wire, the thickness of the hot-dip zinc base alloy solution coating can be reduced obviously, and the adhesion strength of the coating and the appearance quality are improved; and the strength, toughness and corrosion resistance of the steel wire coated with the hot-galvanizing aluminum alloy solutions are all improved obviously.

Owner:JIANGSU FASTEN STEEL CABLE CO LTD +1

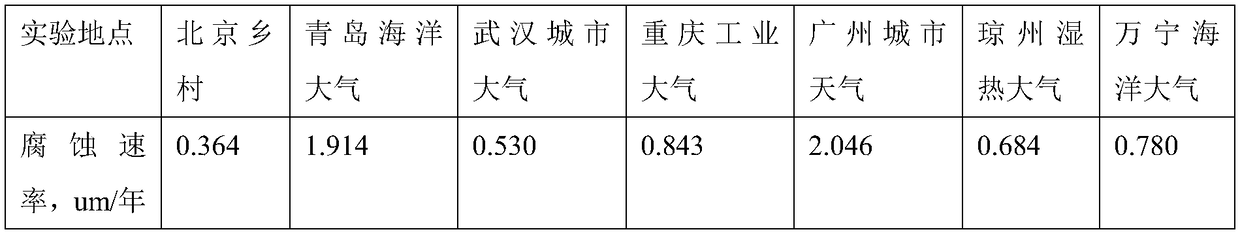

Martensite stainless steel and preparation method thereof

InactiveCN108642391AImprove mechanical propertiesGood resistance to salt spray corrosionChemical compositionMartensitic stainless steel

The invention relates to martensite stainless steel and a preparation method thereof and belongs to the technical field of ferrous metallurgy. The problems to be solved are that martensite stainless steel is poor in corrosion resisting performance, and precious metal molybdenum and tungsten need to be added for improving the corrosion resisting performance of the martensite stainless steel in theprior art. According to the technical scheme, the martensite stainless steel comprises chemical components including, by weight, 0.03%-0.25% of C, smaller than or equal to 1.0% of Si, 0.1%-2.0% of Mn,smaller than or equal to 0.035% of P, smaller than or equal to 0.020% of S, smaller than or equal to 1.5% of Ni, 11.5%-15.0% of Cr, 0.05%-2.0% of Cu, 0.05%-0.6% of V, smaller than or equal to 0.03% of Al, 0.002%-0.05% of N and the balance Fe. The martensite stainless steel has excellent comprehensive mechanical performance and good salt-spray corrosion resisting performance, and is very suitablefor being used in parts of industry like home appliances with the high requirement for corrosion resisting performance.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

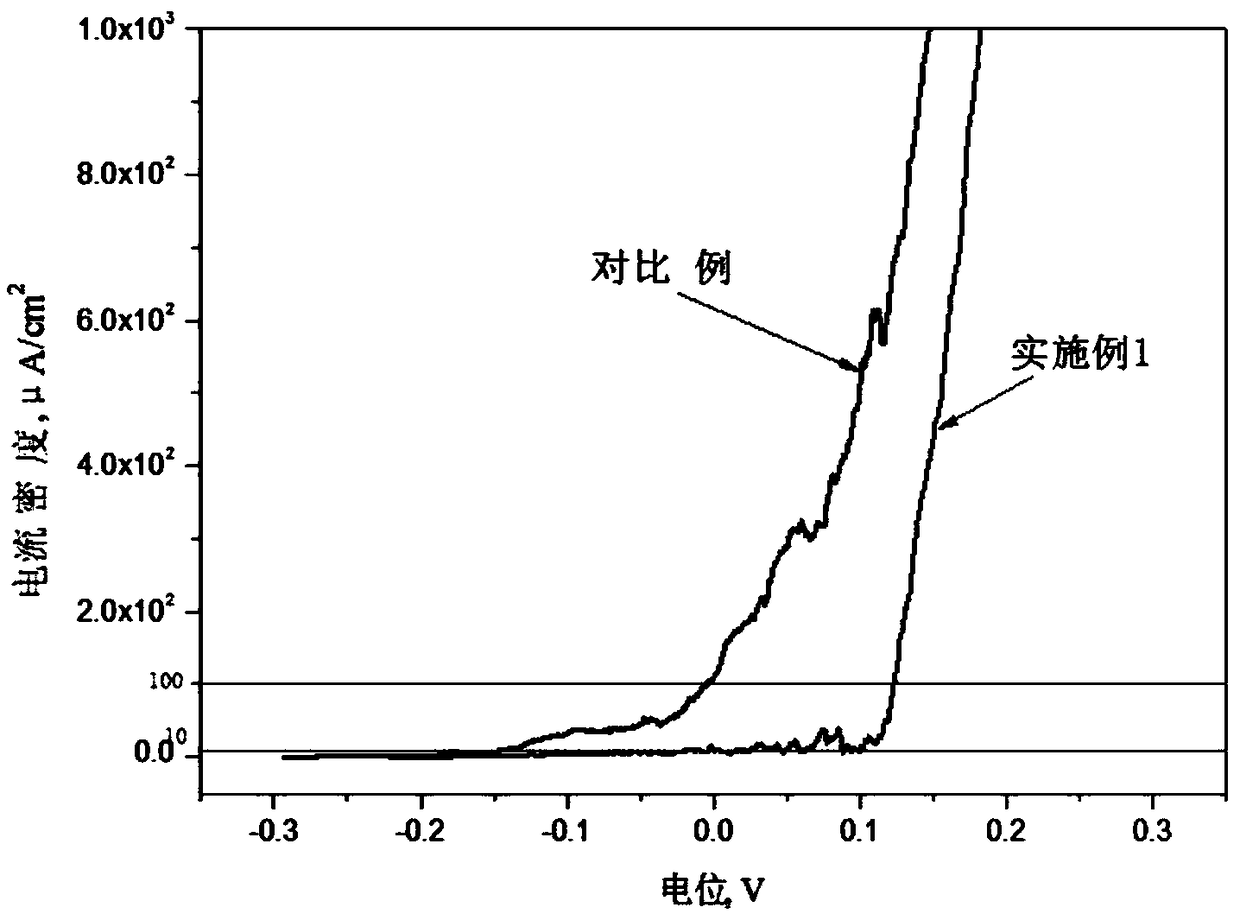

Preparation method of environment-friendly self-healing type titanium/zirconium/molybdenum conversion film on surface of aluminum alloy

InactiveCN108359969AReduce the temperatureReduce investmentMetallic material coating processesSelf-healingMolybdate

The invention provides a preparation method of an environment-friendly self-healing type titanium / zirconium / molybdenum conversion film on the surface of aluminum alloy. The preparation method comprises the following steps that surface pretreatment is conducted on each aluminum alloy sample; a conversion solution is compounded, wherein the conversion solution comprises 0.5-5 g / L of fluotitanate, 0.5-3 g / L of fluozirconate, 1-6 g / L of molybdate, 0.2-3 g / L of a chelating agent, 0.3-3 g / L of a film formation additive and 0.2-0.5 g / L of a pH value adjustment agent, water is added after all components are mixed, stirring is conducted for 30-50 minutes, then, sealing is conducted, and aging is conducted for one day; the conversion film is prepared, wherein each aluminum alloy sample is soaked inthe conversion solution, the continuous and uniform faint-yellow titanium / zirconium / molybdenum conversion film can be formed on the surface of the aluminum alloy, the aluminum alloy samples are takenout and thoroughly cleaned through distilled water, and drying is conducted, so that preparation of the conversion film is completed. By means of the preparation method, the film formation temperatureis low, the film formation time is short, the conversion solution is stable, no chromium is adopted, and environmental friendliness is achieved; the surface of the aluminum alloy is good in corrosionresistance and capable of achieving self-healing; and the preparation method is applicable to various types of aluminum alloy.

Owner:DONGGUAN UNIV OF TECH

Anti-corrosive coating for cement concrete crash-resisting wall and preparation method of anti-corrosive coating

ActiveCN108395816AStrong adhesionImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyAcrylic resin

The invention discloses an anti-corrosive coating for a cement concrete crash-resisting wall. The anti-corrosive coating is prepared from the following raw materials: hydroxylated acrylic resin, epoxyresin, lauryl alcohol polyoxyethylene, mullite, polypropylene glycerol ether, polyimide, polymethylphenylsiloxane, a thickening agent, ethylene bisstearamide, ethoxylated aliphatic alkylamine, a silane coupling agent, propylene glycol monomethyl ether and calcium aluminum borosilicate. The invention also discloses the preparation method of the anti-corrosive coating for the cement concrete crash-resisting wall. The coating prepared by the preparation method disclosed by the invention has the advantages of good adhesion, capability of being well attached to the surface of the cement concrete crash-resisting wall, low possibility of peeling off, excellent alkali resistance, acid resistance and salt spray corrosion resistance; the anti-corrosion performance of the cement concrete crash-resisting wall is greatly improved and the service life of the cement concrete crash-resisting wall is prolonged.

Owner:内蒙古高远工程科技发展有限公司

Corrosion-resistant, waterproof, mildew-proof and damp-proof coffin chamber

InactiveCN106760906AMeet the requirementsExpress different needsBurial vaultsMonumentsBrickHeat resistance

The invention provides a corrosion-resistant, waterproof, mildew-proof and damp-proof coffin chamber. The corrosion-resistant, waterproof, mildew-proof and damp-proof coffin chamber comprises a coffin chamber body directly designed in soil and is characterized in that the coffin chamber body comprises a coffin chamber shell and a coffin chamber cover which are made of PPO; the upper peripheral edge of the lateral wall of the coffin chamber shell is provided with a circle of protruding limit protrusion part; the lower peripheral edge of the coffin chamber cover is provided with a circle of groove corresponding to the limit protrusion part; a position between the limit protrusion part and the groove is filled with engineering silica gel. The corrosion-resistant, waterproof, mildew-proof and damp-proof coffin chamber has the advantages that the novel coffin chamber thoroughly overturns a traditional coffin chamber built by simple and cold bricks, stone and cement; the corrosion-resistant, waterproof, mildew-proof and damp-proof coffin chamber is excellent in physical mechanical performance, heat resistance and electric insulating performance, low in moisture absorption, high in strength and good in size stability, and the waterproof level of the coffin chamber reaches IP68.

Owner:张洪昌 +1

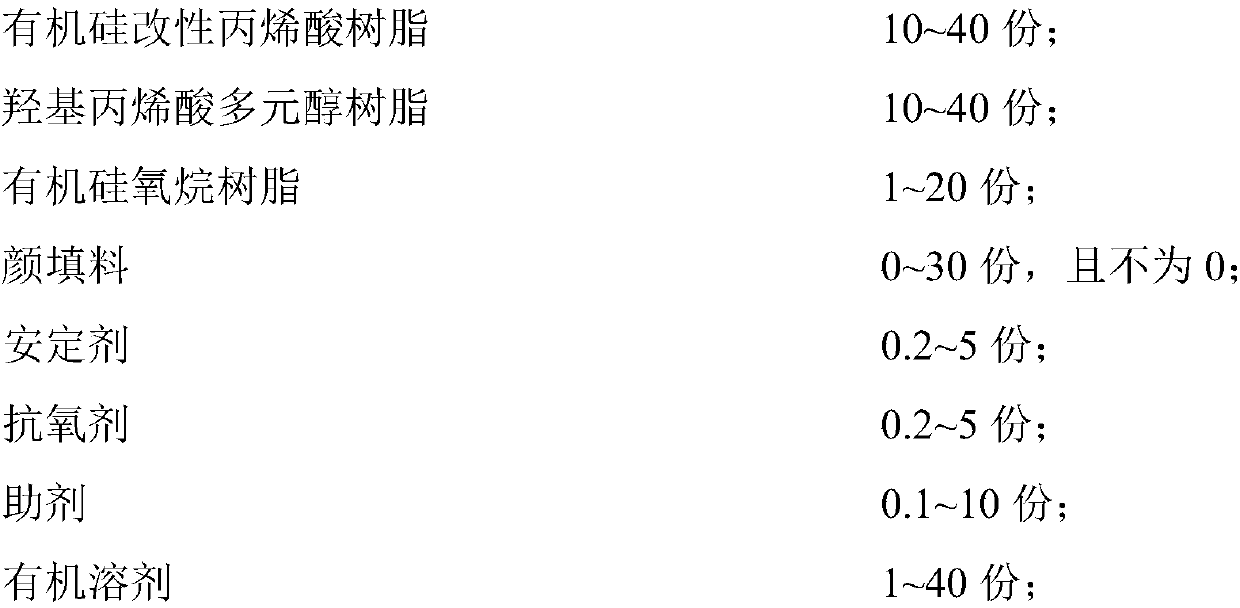

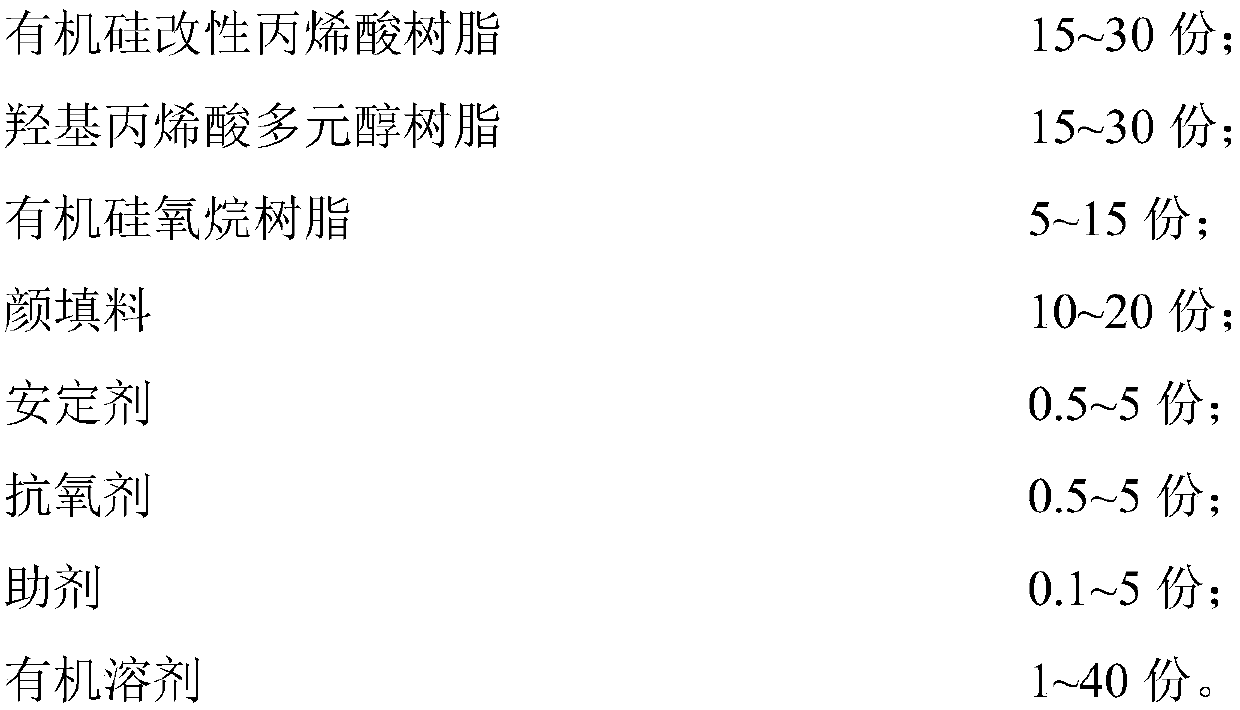

High pressure steam impact resistant coating for metal materials and preparation method of coating

ActiveCN109679478AImprove curing effectIncrease crosslink densityAntifouling/underwater paintsPaints with biocidesCross-linkAcrylic resin

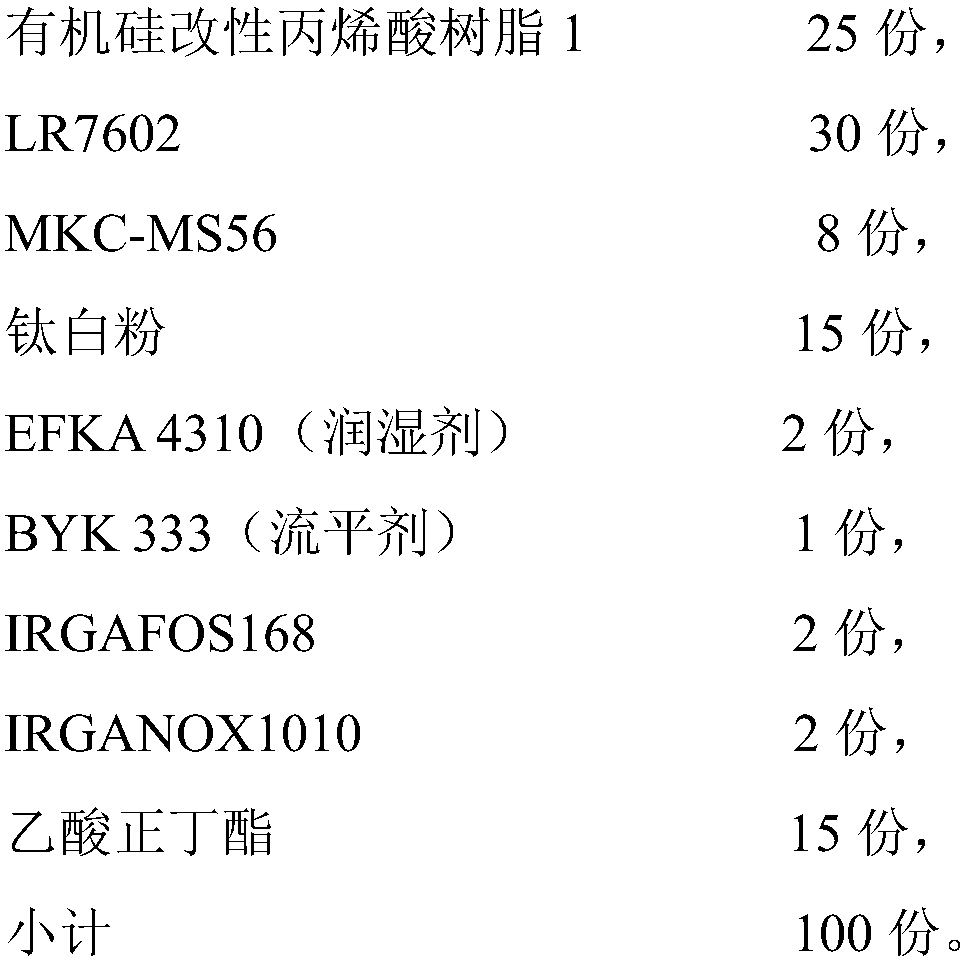

The invention relates to a high pressure steam impact resistant coating for metal materials and a preparation method of the coating. The coating is prepared from the following components in parts by weight: A) 10-40 parts of silicone-modified acrylic resin, B) 10-40 parts of hydroxy acrylic polyol resin, C) 1-20 parts of hydrolyzable organosiloxane resin, D) 0-30 parts of pigments and fillers, E)0.1-10 parts of an organophosphorus compound stabilizer, F) 0.1-10 parts of an organic phenolic antioxidant, G) 0.1-10 parts of additives such as a wetting leveling agent and the like, H) 1-40 parts of an organic solvent and I) a cross-linking agent. Compared with the prior art, the coating has excellent adhesion, water resistance, high pressure steam washing resistance and other film forming properties to metal materials. According to the needs of model design, the glossiness of a coating film is adjustable, and the coating is excellent in resistance to various chemicals, has an adjustable design appearance, is especially suitable for automotive exterior parts used in cold areas, and has the advantages of corrosion resistance, warm water resistance, high pressure steam impact resistance and the like.

Owner:DONGLAI COATING TECH SHANGHAI

Preparation method of waterborne epoxy soybean oil modified epoxy-ester anticorrosive paint

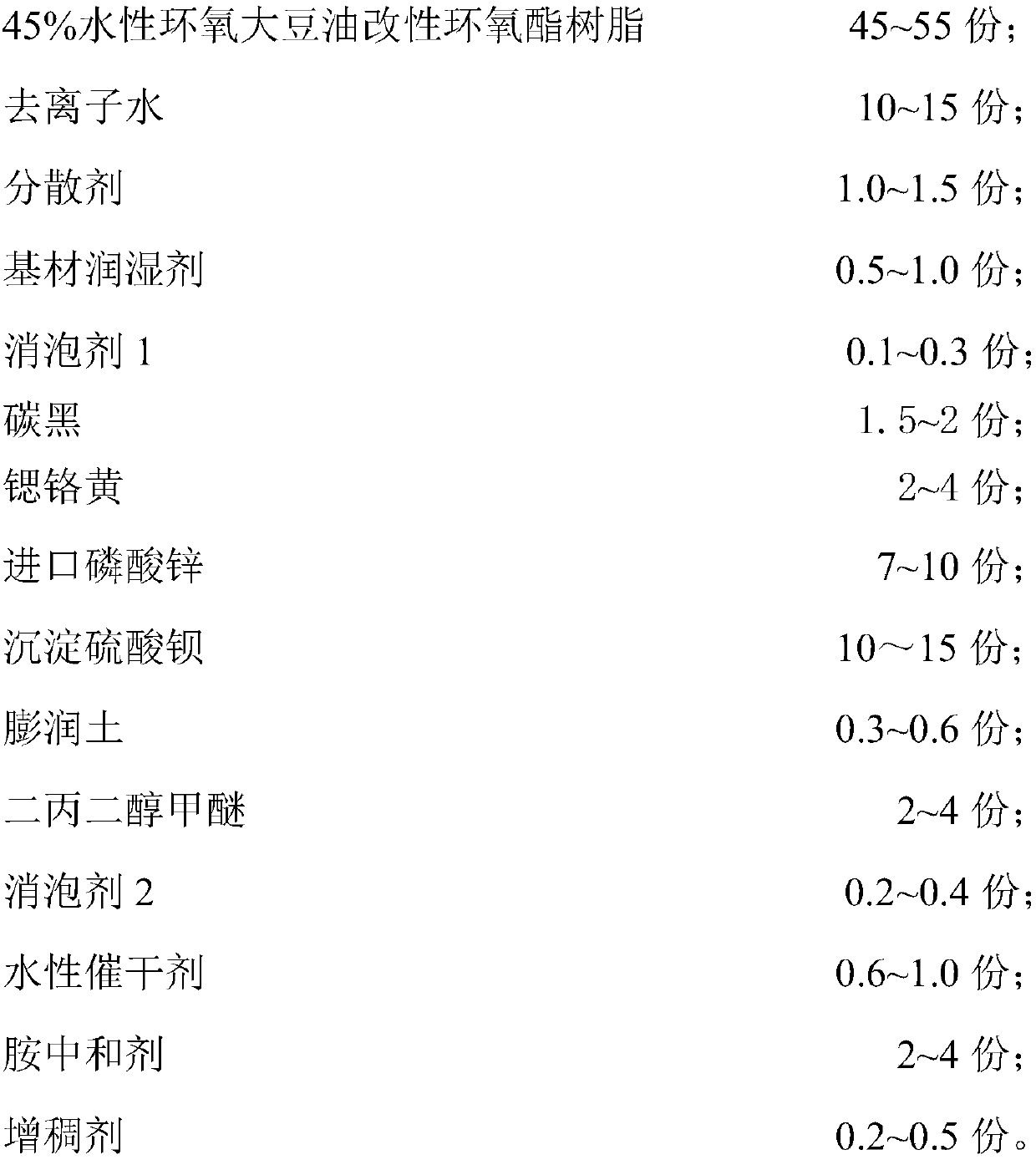

InactiveCN107916049ASolve cleaningAddress riskAnti-corrosive paintsEpoxy resin coatingsEpoxyZinc phosphate

The invention discloses a waterborne epoxy soybean oil modified epoxy-ester anticorrosive paint and its preparation method. The paint is prepared by 1), preparing 45% of waterborne epoxy soybean oil modified epoxy-ester resin; 2), preparing resin-free mill the raw material comprises deionized water, wetting agent, dispersing agent, antifoaming agent 1, strontium yellow, imported zinc phosphate, carbon black, precipitated barium sulphate and waterborne bentonite; 3), paint mixing: the resin-free mill base, 45% of waterborne epoxy soybean oil modified epoxy-ester resin, drier, antifoamingagent 2, dimethylethanolamine, and thickening agent are mixed to obtain the waterborne epoxy soybean oil modified epoxy-ester anticorrosive paint. The product is excellent in salt-spray corrosion resistance, and can meet the use of an axle under the high salt-spray corrosion resistance environment; the product is good in dryness and can meet the requirement of the existing axle coating line; the thickness of a dry film of a primary film is up to 60 mu m, and the product is free from sagging and good in construction property; the paint is short in coating cycle, low in VOC emission, and is safeand environment-friendly waterborne heavy anti-corrosive paint.

Owner:陕西宝塔山油漆股份有限公司

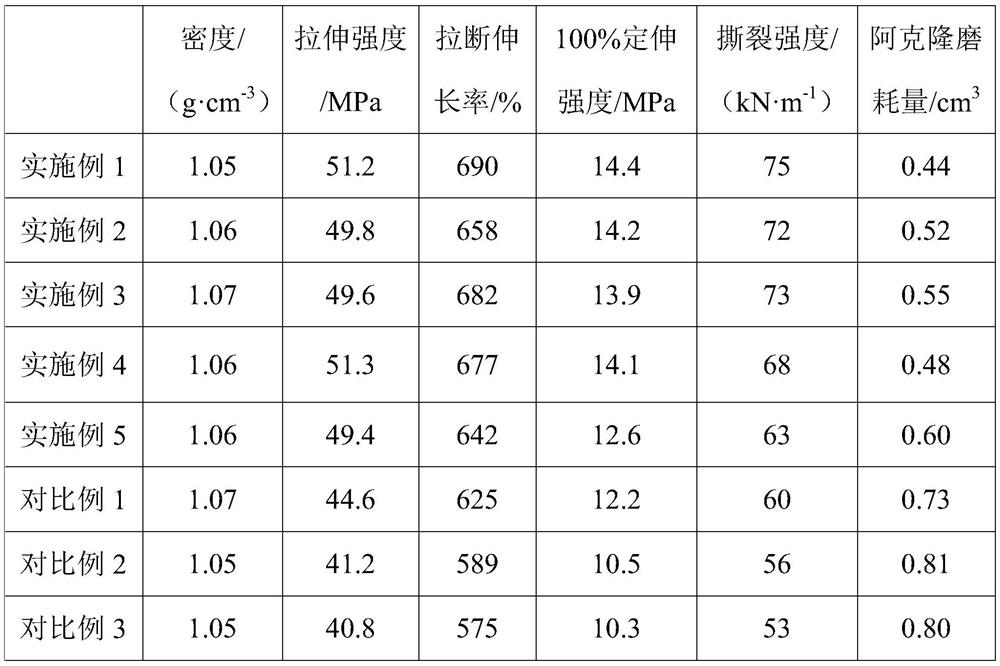

Marine high-strength tear-resistant rubber material and preparation method thereof

The invention relates to the field of high polymer materials, in particular to a marine high-strength tear-resistant rubber material and a preparation method thereof, wherein the rubber material includes the following components: natural rubber, epoxidized natural rubber, aminated solution polymerized styrene-butadiene rubber, liquid polyisoprene rubber, epoxidized butadiene rubber, a coupling agent modified one-dimensional carbon nanomaterial, white carbon black, carbon black, zinc oxide and an auxiliary agent. The prepared rubber material has the advantages of favorable mechanical properties, high tensile strength, high tear strength, favorable salt spray corrosion resistance and lower density, and is suitable for manufacturing marine rubber parts.

Owner:湖南弘辉科技有限公司

A kind of high-strength wear-resistant modified natural rubber and its preparation method

The invention discloses a high-strength wear-resistant modified natural rubber, which comprises the following raw materials in parts by weight: 60-70 parts of natural rubber, 15-20 parts of EPDM rubber, 6-9 parts of butadiene rubber, reinforcing agent 8-10 parts, 2.5-3.5 parts of epoxy resin, 2-3 parts of silane coupling agent, 1-2 parts of accelerator, 1-2 parts of anti-aging agent, 0.3-0.5 parts of emulsifier, 4.5-5 parts of plasticizer . The rubber obtained in the invention shows good mechanical strength at high temperature and low temperature, and also has excellent wear resistance, good sunlight resistance, ultraviolet aging resistance and weather resistance. In addition, the rubber obtained in the present invention also has good salt spray corrosion resistance, excellent flame retardancy, good comprehensive performance, long service life, and can meet various fields, such as aviation products and automotive wipers, sealing strips, sealing rings, etc. Requirements.

Owner:贵州科润密封科技有限公司

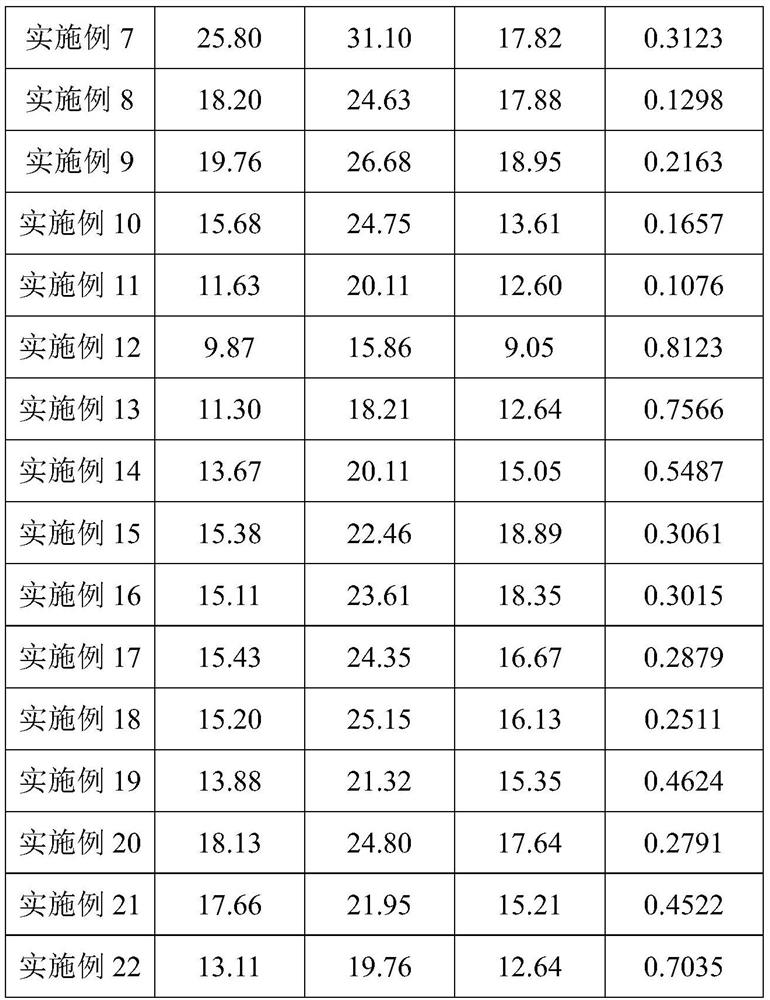

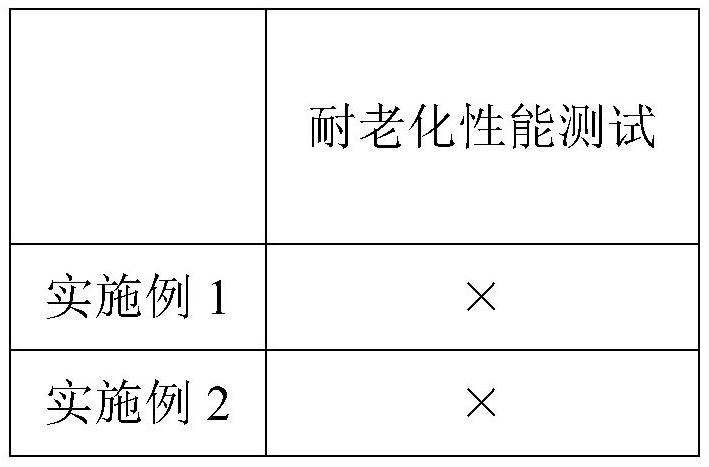

Rust-proof emulsion for spring and preparation method thereof

InactiveCN107556441AGood resistance to salt spray corrosionAnti-corrosive paintsPolymer scienceEmulsion

The invention provides a rust-proof emulsion for a spring and a preparation method thereof. The rust-proof emulsion is prepared from methyl methacrylate, butyl acrylate, a phosphate monomer, an epoxyacrylate monomer, an emulsifying agent and deionized water. The preparation method comprises the following steps: a) preparing the phosphate monomer; b) preparing the epoxy acrylate monomer; c) preparing a pre-emulsion; d) preparing a polymer emulsion. The invention discloses the rust-proof emulsion for the spring and the preparation method thereof. The rust-proof emulsion is prepared by using a pre-emulsification process and a semi-continuous seed polymerization method, the obtained rust-proof emulsion not only has an excellent salt-spray corrosion resistance, but also is recyclable, and waste liquid cannot be generated to pollute the environment.

Owner:常熟市瑞思知识产权服务有限公司

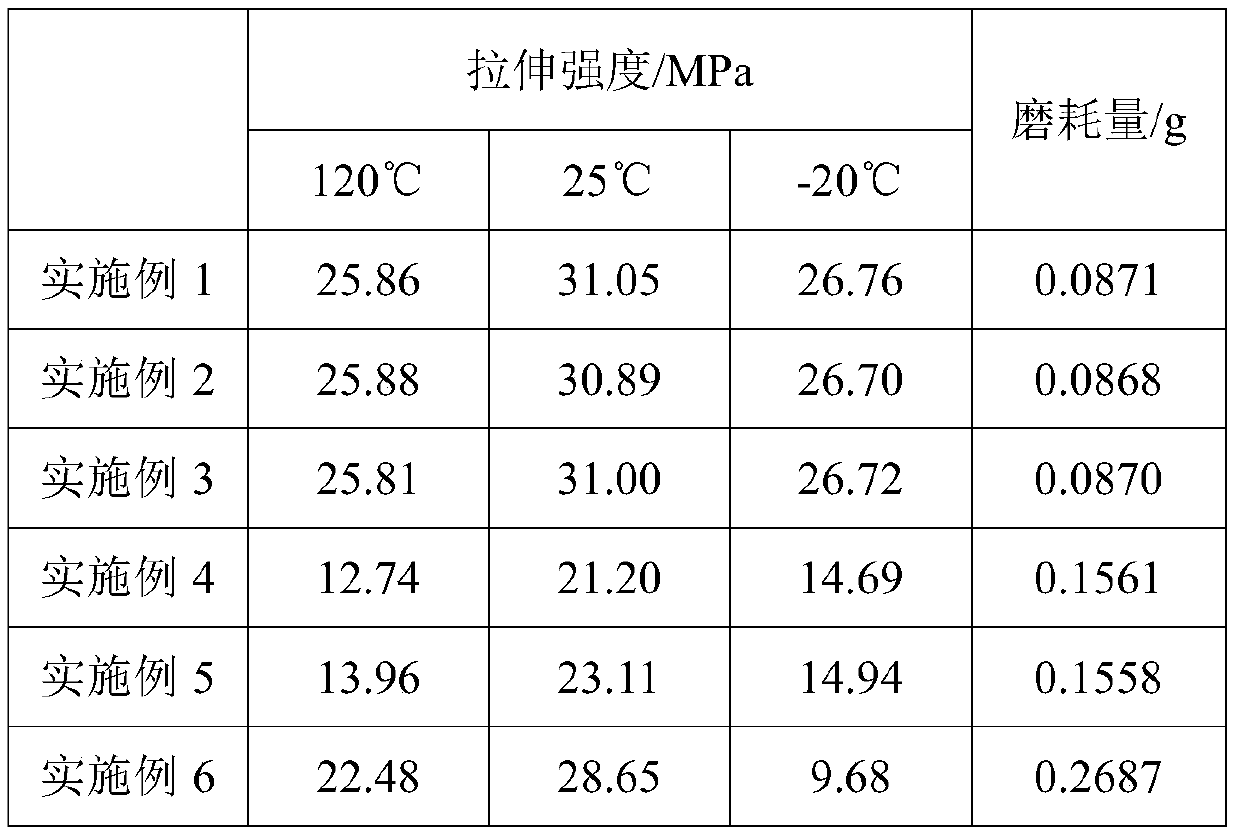

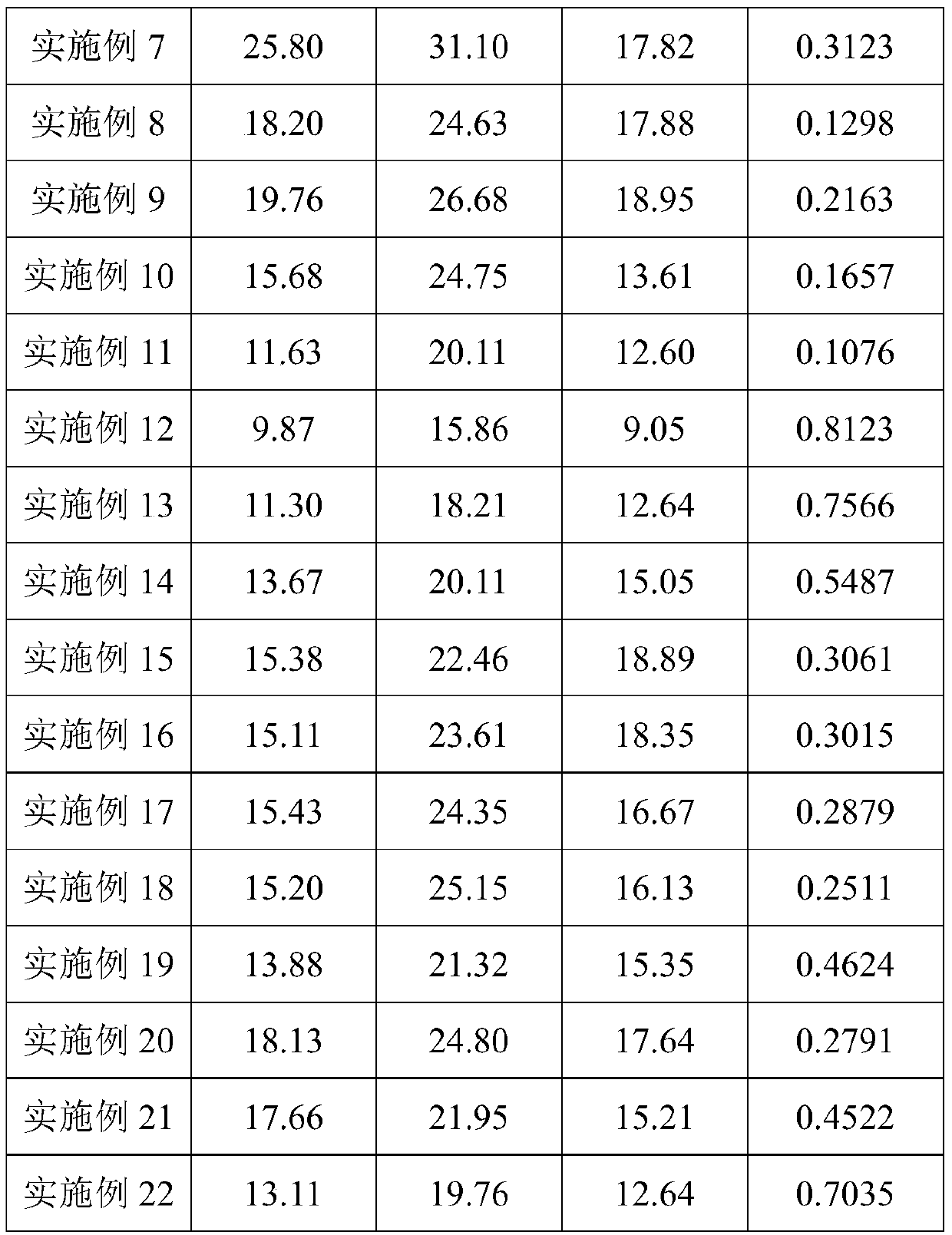

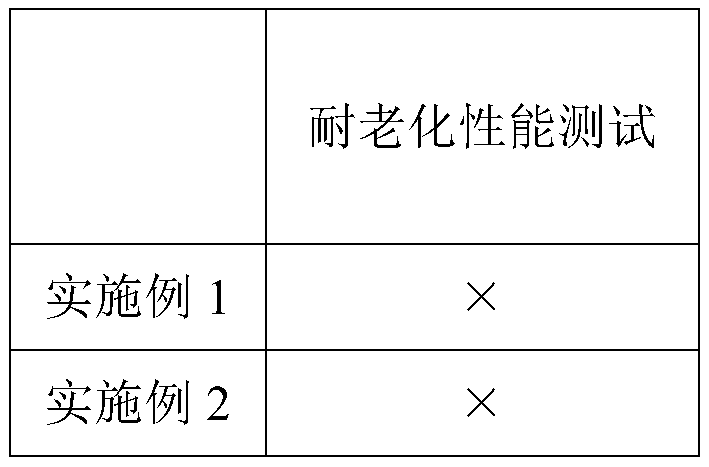

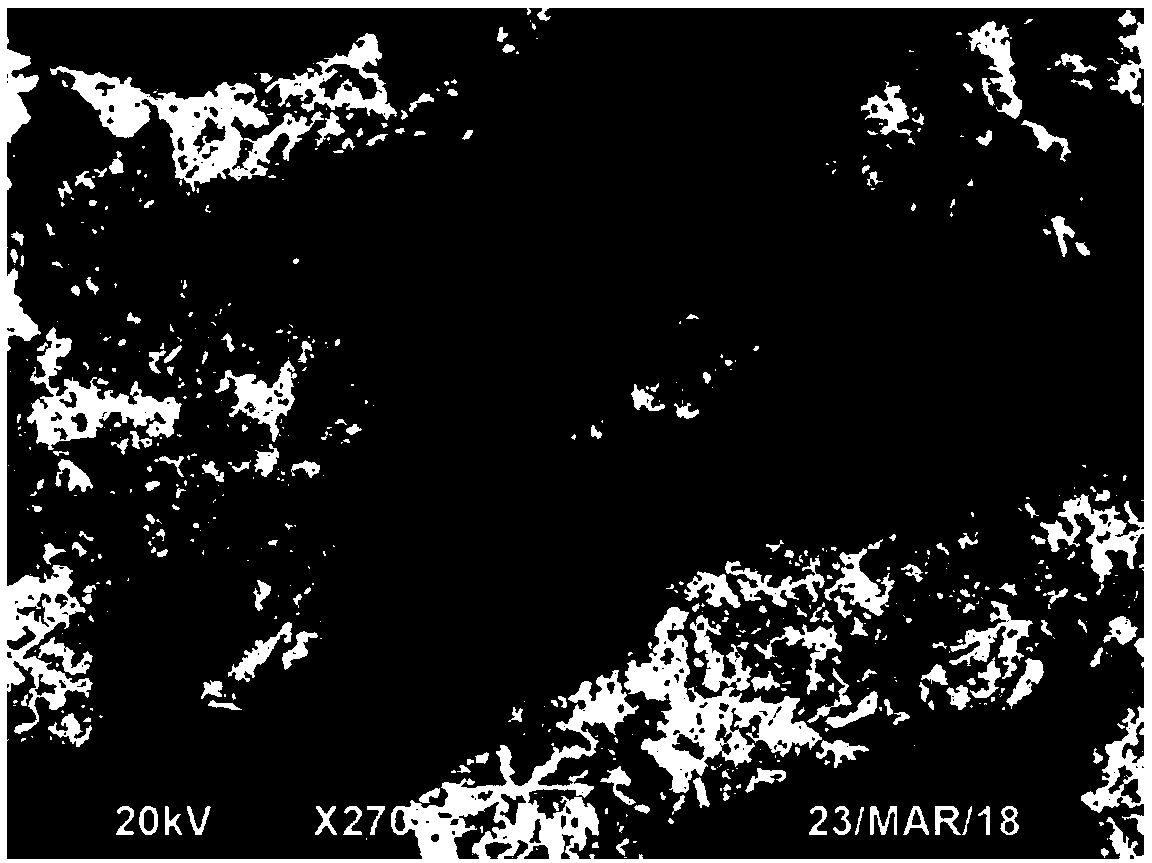

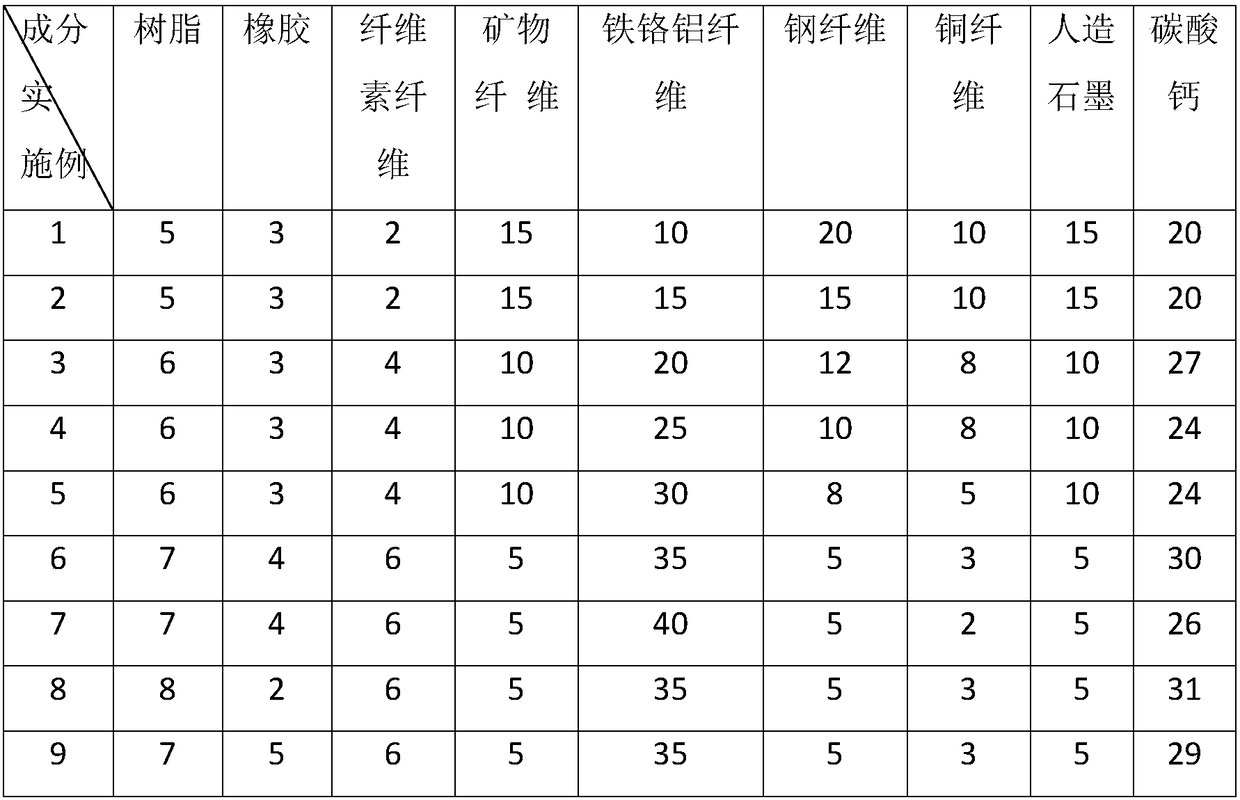

Weather-resistant high-metal friction plate for military vehicle and preparation method thereof

ActiveCN108757784AGood resistance to salt spray corrosionIncrease coefficient of frictionOther chemical processesFriction liningChromiumCalcium carbonate

The invention belongs to the technical field of friction plates for vehicles and particularly relates to a weather-resistant high-metal friction plate for a military vehicle and a preparation method thereof. The weather-resistant high-metal friction plate for the military vehicle comprises raw materials including the following components of, by weight, 10-40% of iron-chromium-aluminum fibers, 7-30% of metal fibers, 7-21% of non-metal fibers, 5-15% of artificial graphene, 5-8% of resin, 2-5% of rubber and the balance calcium carbonate. The raw materials are weighed and mixed according to the designed ratio of all the components, the raw materials are subjected to hot-press forming, solidified and machined, and thus the weather-resistant high-metal friction plate is obtained. The weather-resistant high-metal friction plate is suitable for various harsh climates and environments and good in high-low temperature resistance and corrosion resistance, has the characteristics of high and stable friction coefficient and rapid and safe emergency braking, and is a high-performance special brake pad special for the military vehicle.

Owner:CENT SOUTH UNIV +1

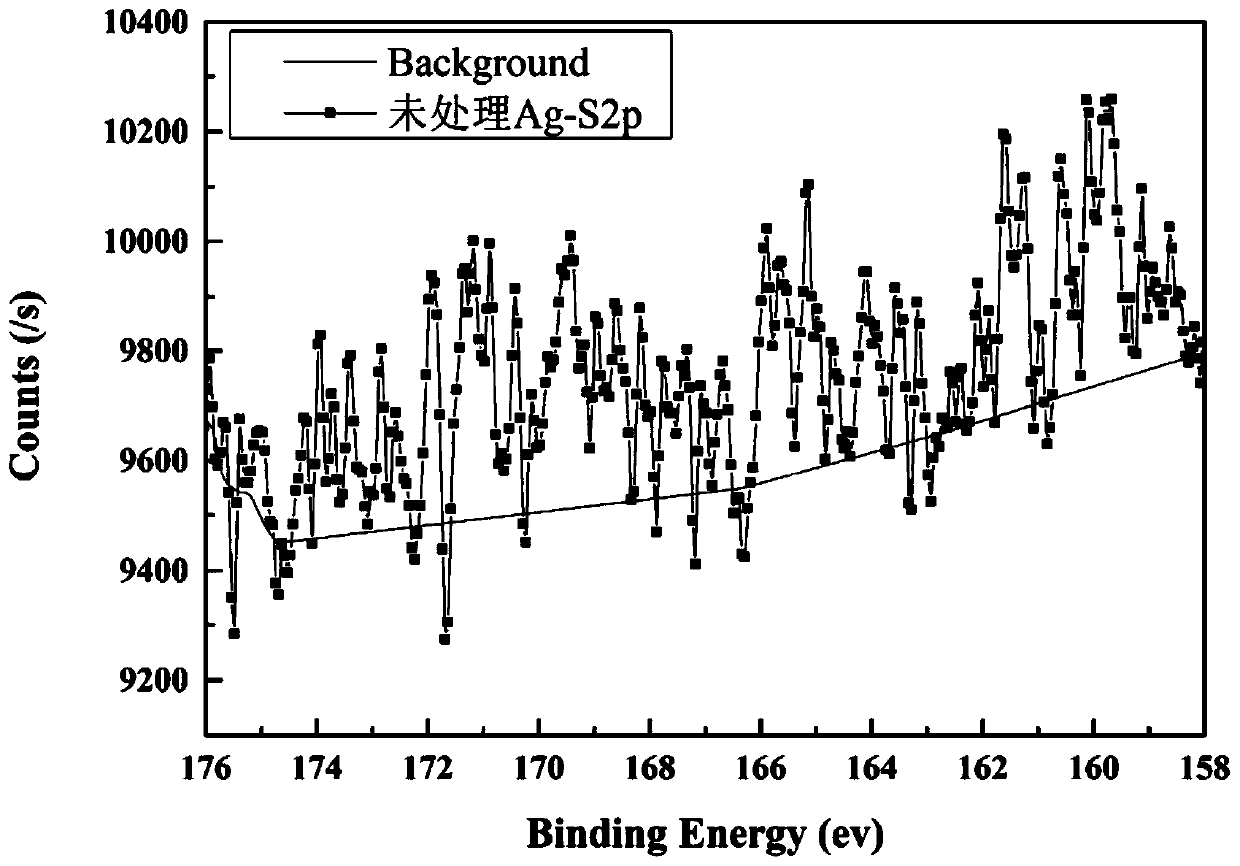

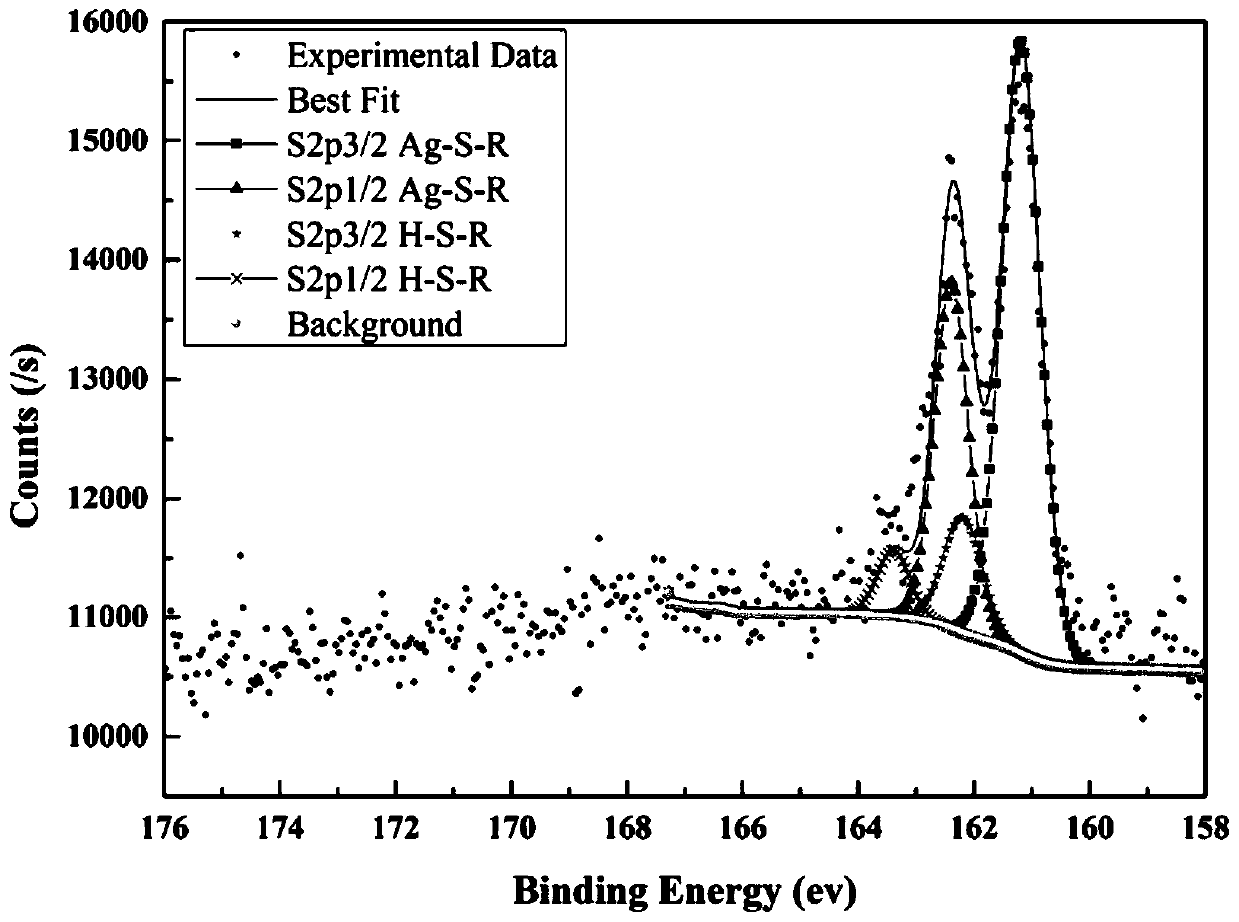

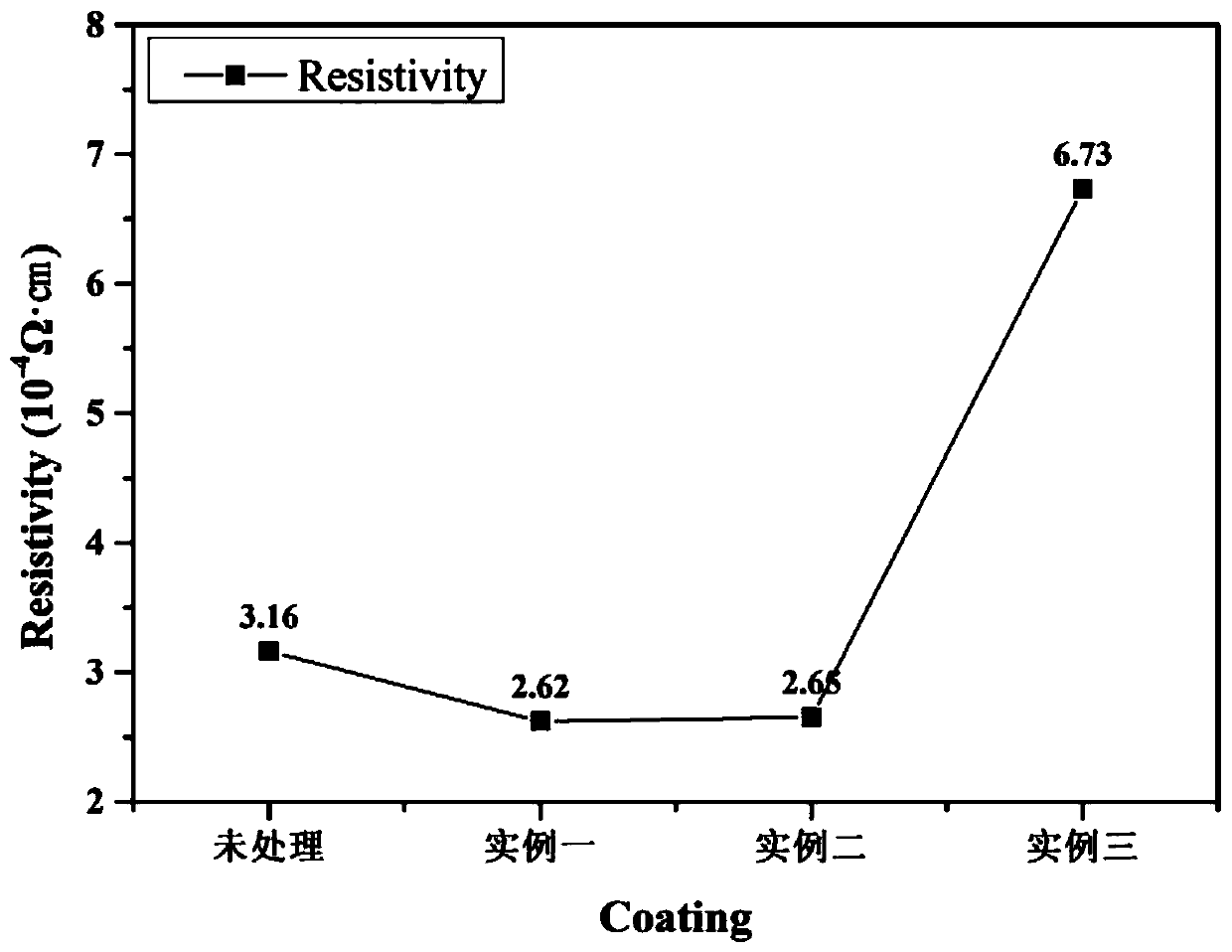

Modified silver powder conductive coating and preparation method thereof

ActiveCN111057441AMicroporous reductionReduce the number of gapsAnti-corrosive paintsEpoxy resin coatingsHigh humidityConductive coating

The invention belongs to the technical field of conductive coatings, and particularly relates to a modified silver powder conductive coating and a preparation method thereof. The method is consideredfrom a brand-new perspective; the surface of silver powder is modified, organic matters are grafted on the surface of the silver powder, and the organic matters on the surface of the silver powder caneffectively improve the interface characteristics between the silver powder and resin; the number of micropores and gaps in the conductive coating is reduced; corrosive substances such as water vaporare better prevented from entering a coating layer of the conductive coating; the silver powder is prevented from easily generating electrochemical corrosion with a metal substrate due to high conductivity of the silver powder; especially in the coastal environment with high humidity and high salt concentration, the problem of failure of the conductive coating is solved, longer service life of the conductive coating on a metal substrate is ensured, the conductive coating has good salt mist corrosion resistance in a system formed by the conductive coating and tinplate, and the service life ofthe conductive coating is greatly prolonged.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Preparation method of salt-fog-corrosion-resistant silane coupling agent

InactiveCN106350805ASimple methodEasy to operateMetallic material coating processesFreeze-dryingEvaporation

The invention discloses a preparation method of a salt-fog-corrosion-resistant silane coupling agent, belonging to the technical field of silane coupling agents. The method comprises the following steps: stirring trimethylolethane, triethylamine and dichloromethane, dropwisely adding a mixed solution formed by uniformly mixing alpha-bromoisobutyryl bromine and dichloromethane, carrying out reaction in a dark place, oscillating, standing to stratify, carrying out rotary evaporation concentration on the organic layer, carrying out freeze-drying lyophilization, putting the product, cuprous chloride and 2,2'-dipyridine into a reaction kettle, adding styrene, butyl methacrylate, a silane coupling agent and the like, stirring to react, and finally, dropwisely adding methanol to precipitate the high polymers in the reaction kettle, thereby obtaining the salt-fog-corrosion-resistant silane coupling agent. The self-made high-molecular initiator reacts with the conventional silane coupling agent to obtain the high-molecular silane coupling agent. The high-molecular silane coupling agent can form a thick protective layer on the metal surface, and has favorable shielding properties for the metal material surface. The example proves that the obtained silane coupling agent can not produce white rust after a long-time salt fog test.

Owner:董晓

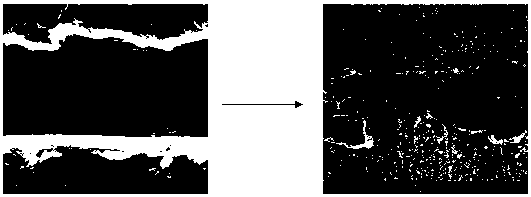

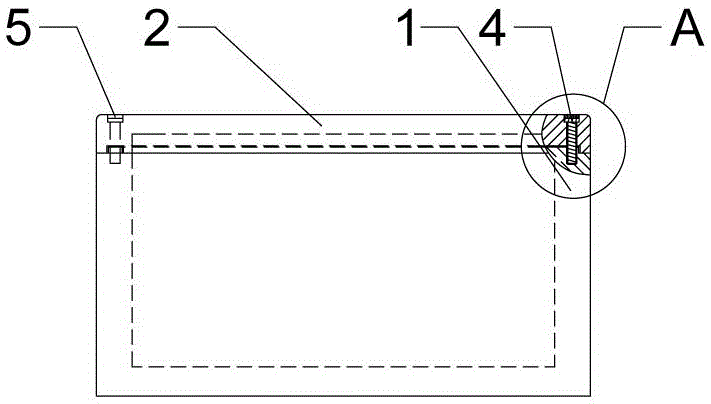

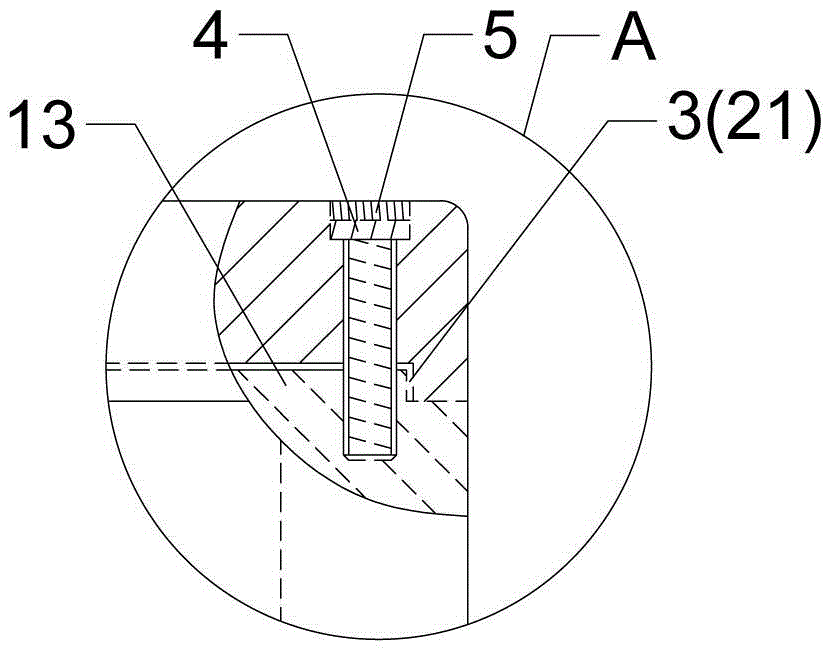

Parallel seam welding alloy cover plate for integrated circuit packaging and preparation method thereof

PendingCN110977361AEnhanced salt spray corrosion resistanceAvoid exposureSemiconductor/solid-state device detailsSolid-state devicesIntegrated circuit manufacturingAlloy

The invention discloses a parallel seam welding alloy cover plate for integrated circuit packaging and a preparation method thereof, and belongs to the technical field of integrated circuit manufacturing. The preparation method of the parallel seam welding alloy cover plate for the integrated circuit packaging comprises the following steps of spraying the four side surfaces of an alloy cover platecolumn to form a first nickel protective layer by using a plasma spraying process; cutting the alloy cover plate column into a single alloy cover plate in the transverse direction; performing deburring treatment on the alloy cover plate; forming a T-shaped alloy cover plate body by adopting machining or chemical corrosion; and plating nickel on the outer surface of an alloy cover plate body to form a second nickel protection layer. According to the parallel seam welding alloy cover plate for the integrated circuit packaging and the preparation method thereof, the four side surfaces of the alloy cover plate column is sprayed to form the first nickel protection layer, the single alloy cover plate is formed after cutting, the side surfaces of the alloy cover plate column are sprayed to formthe first nickel protection layer easily, the thickness of the obtained first nickel protection layer is relatively thick, and the salt spray corrosion resistance can be higher.

Owner:58TH RES INST OF CETC

Wear-resistant paint applied to surface coating of metal bolt piece

PendingCN114262553AGood dispersionGood resistance to salt spray corrosionAnti-corrosive paintsMeth-Acrylic resin

The invention discloses a wear-resistant coating applied to a surface coating of a metal bolt piece. The wear-resistant coating is prepared from the following components in parts by weight: 30 to 40 parts of methyl etherified high imino melamine resin emulsion, 30 to 40 parts of acrylic resin emulsion, 2.5 to 3 parts of hydrochloric acid solution, 20 to 23 parts of sodium chloride, 1.7 to 2 parts of stannous chloride, 0.6 to 1.3 parts of hydroquinone, 8 to 16 parts of water, 0.5 to 1 part of flatting agent, 0.4 to 0.6 part of modified polydimethylsiloxane and 8 to 12 parts of coalescing agent. Methyl etherified high-imino melamine resin emulsion and acrylic resin emulsion are used as reaction matrixes and matched with components such as a hydrochloric acid solution, sodium chloride, stannous chloride and hydroquinone, and a film layer which is good in dispersity and excellent in adhesive capacity can be formed through curing under promotion of a coalescing agent; and the formed film layer has the characteristic of good salt spray corrosion resistance.

Owner:惠州市惠阳区精艺实业有限公司

Chromium-free passivation treatment process for aluminum alloy surface

InactiveCN111893472AReduce tensionImprove solubilityMetallic material coating processesSolution treatmentLaser processing

The invention discloses a chromium-free passivation treatment process for an aluminum alloy surface and relates to the technical field of aluminum alloys. The chromium-free passivation treatment process for the aluminum alloy surface comprises the following steps: (1) grinding; (2) tannic acid solution treatment; (3) femtosecond laser processing; (4) passivation. According to the method, a uniformand compact passivation film is formed on the surface of the aluminum alloy through passivation, and after neutral salt fog treatment, the passivation film has excellent salt fog corrosion resistanceand can better protect the aluminum alloy; and the contact angle of the surface of the passivation film formed by the method is greatly increased, so that the hydrophobic property of the surface of the aluminum alloy after passivation treatment by the process is obviously improved.

Owner:合肥卓汇新材料科技有限公司

Molybdate passivating liquid for continuous hot-dipping galvanizing steel plate

ActiveCN101429661BGood resistance to salt spray corrosionMetallic material coating processesMolybdatePhosphoric acid

Owner:CHANGSHU HUAYE STEEL STRIP

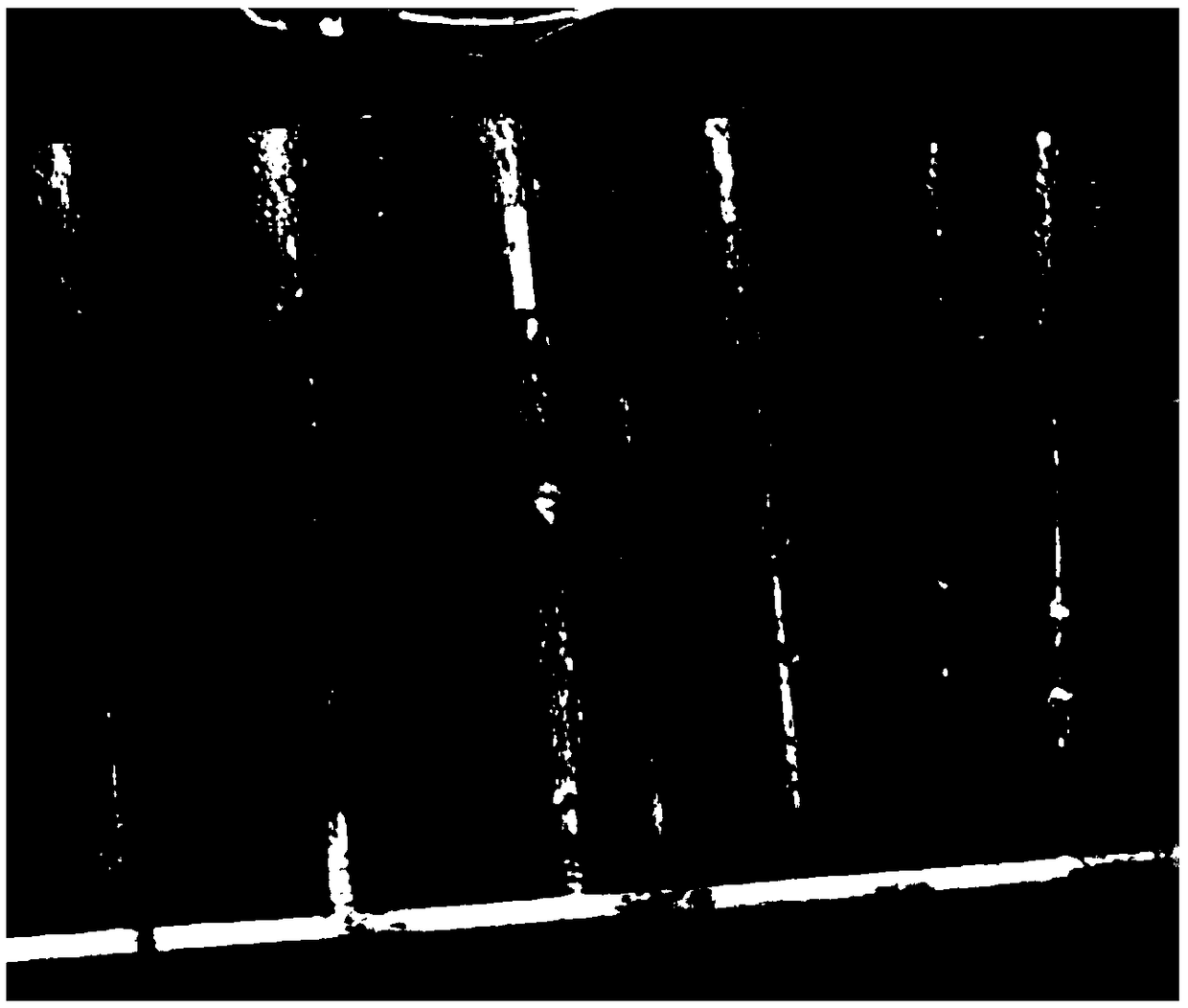

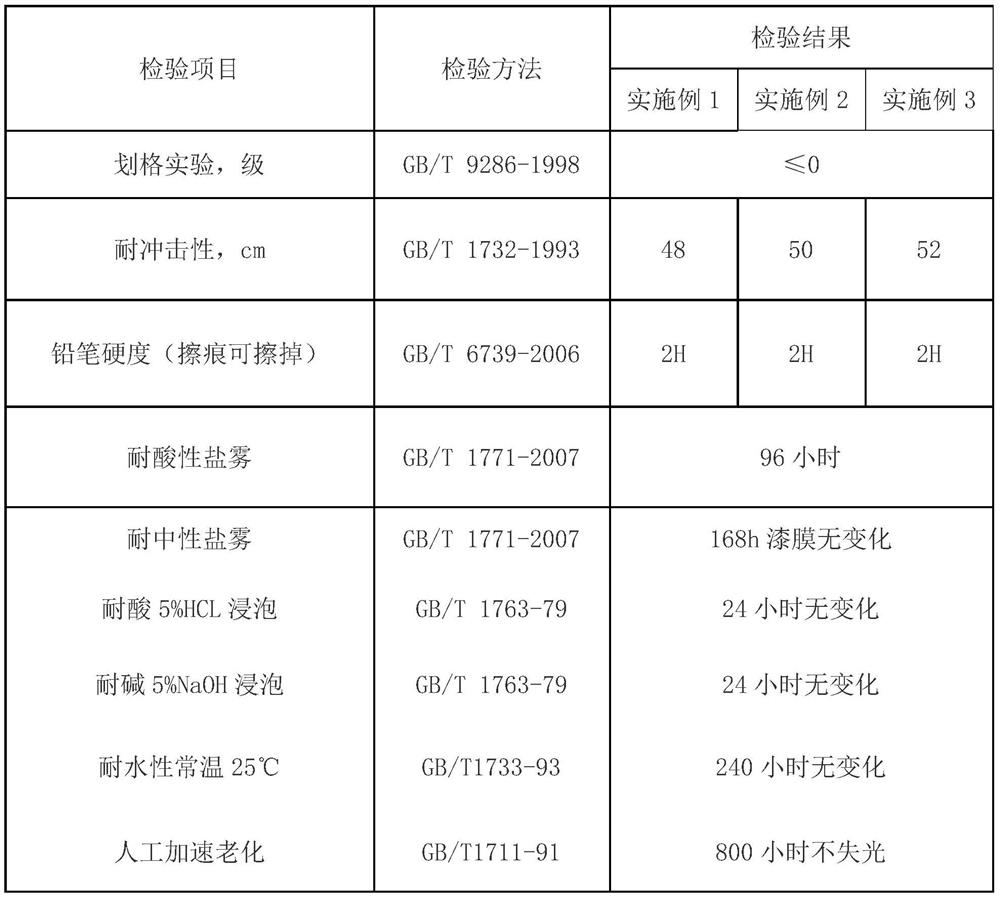

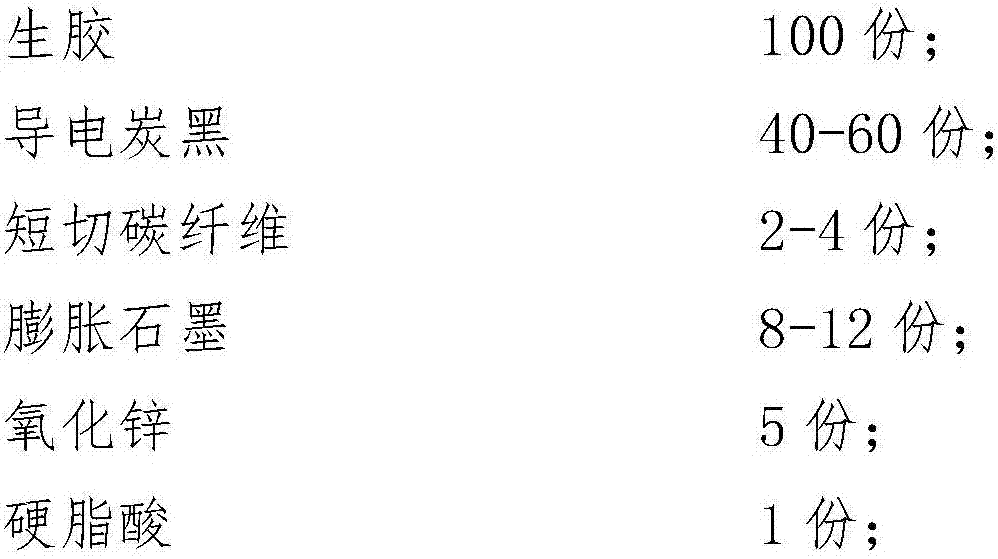

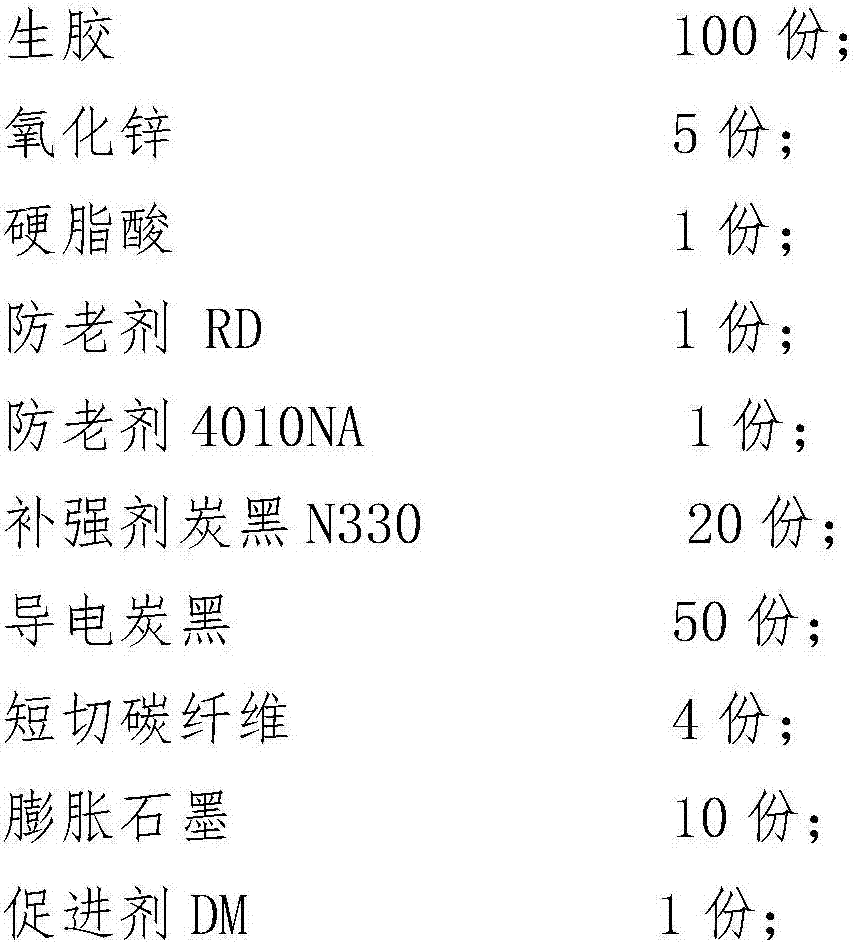

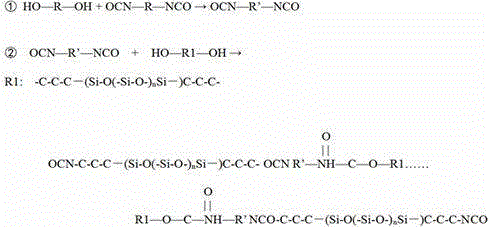

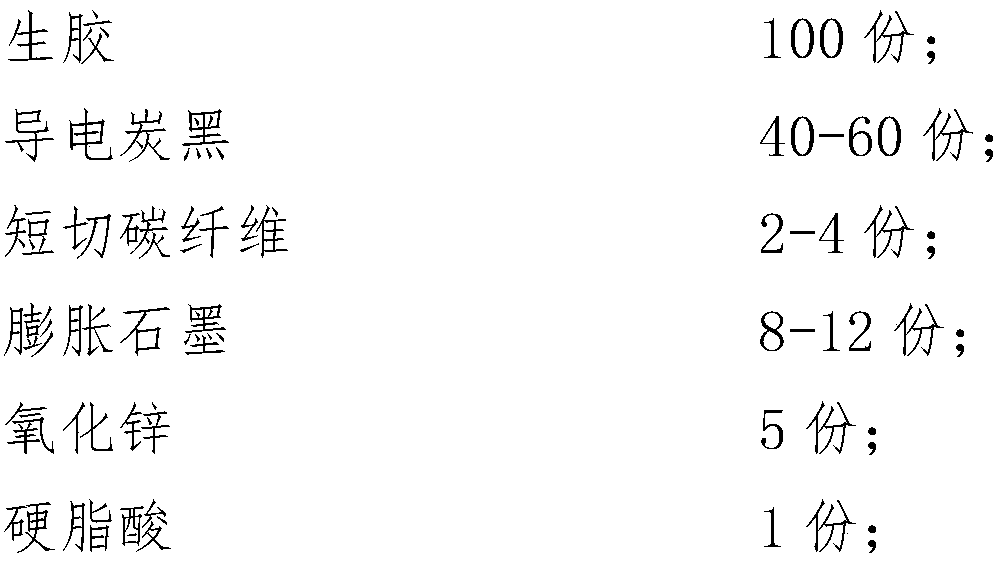

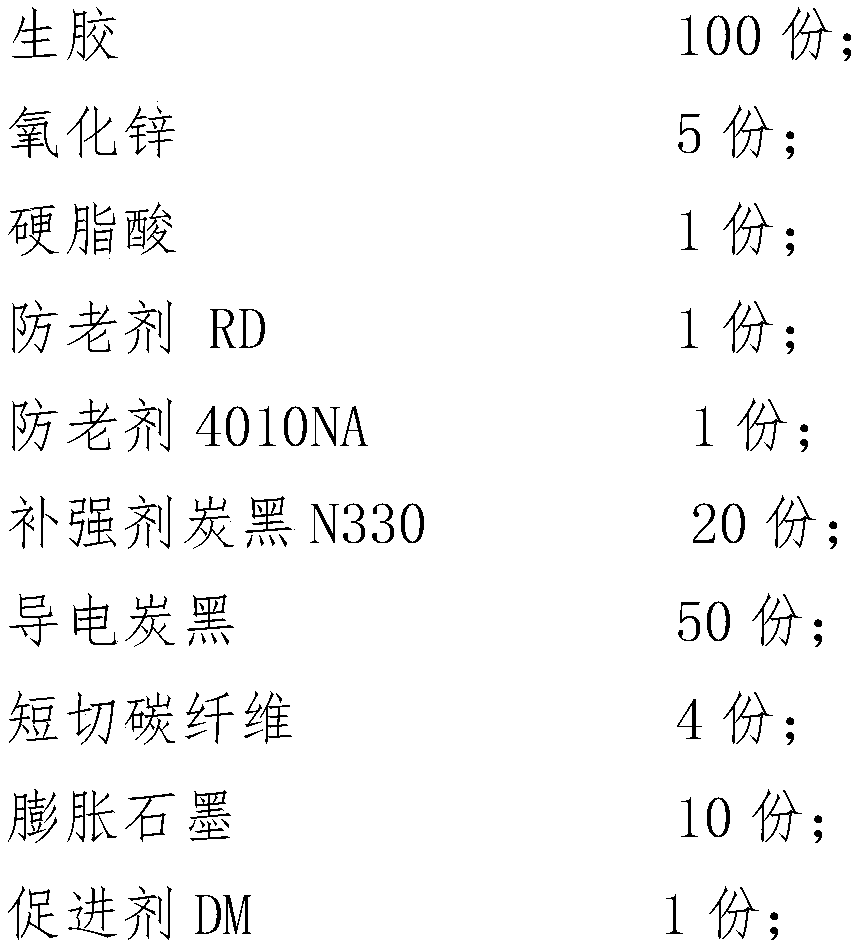

Salt-spray corrosion resistant electromagnetic shielding composite material and preparation method thereof

ActiveCN107325344AImprove corrosion resistanceGood electromagnetic shielding stabilityFiberCarbon fibers

The invention relates to the field of composite materials, and provides a salt-spray corrosion resistant electromagnetic shielding composite material and a preparation method of the salt-spray corrosion resistant electromagnetic shielding composite material. The electromagnetic shielding composite material mainly comprises raw rubber, conductive carbon black, expanded graphite and chopped carbon fibers, and the salt-spray corrosion resistant electromagnetic shielding composite material is finally subjected to vulcanization molding by using the mixing way of a double-roller open mill. The salt-spray corrosion resistant electromagnetic shielding composite material has high electromagnetic shielding effectiveness and salt-spray corrosion resistance, and excellent comprehensive performances, is very suitable for being applied as a shielding material in the field of marine environments with higher requirements on the salt-spray corrosion resistance and shielding performances, and further has good market prospects.

Owner:QINGDAO UNIV OF SCI & TECH +2

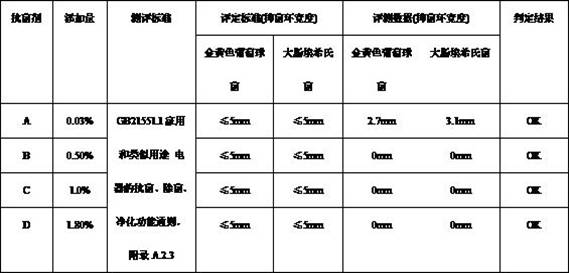

Earphone earplug and preparation method thereof

ActiveCN112822606AEnhanced surface contactAdd a small proportionChemical vapor deposition coatingEarpiece/earphone manufacture/assemblyMicrobiologyHeadphones

The invention provides an earphone earplug, which comprises an earplug body, the earplug body is an antibacterial silica gel earplug, the antibacterial silica gel earplug is made of antibacterial silica gel, the antibacterial silica gel comprises an antibacterial agent finished product, the antibacterial silica gel comprises 0.04 wt%-6wt% of the antibacterial agent finished product, the antibacterial agent finished product comprises a nano antibacterial agent and a porous antibacterial agent carrier, and the antibacterial silica gel comprises 0.03 wt%-1.8 wt% of the nano antibacterial agent in percentage by weight; the antibacterial agent finished product contains the porous antibacterial agent carrier which has an ultrahigh specific surface area, so that the dispersion of effective components of the antibacterial agent is facilitated, the surface contact property of the antibacterial agent is greatly improved, the utilization rate of the inner surface of the antibacterial agent is improved, and the adding proportion of the antibacterial agent is greatly reduced; the addition amount of the antibacterial agent is low, the problem that the original performance of the silica gel can be influenced by the addition amount of the antibacterial agent with a high proportion is solved, and bad hidden dangers such as the mechanical performance and the wearing skin-friendly comfort of the antibacterial earplug are avoided.

Owner:SHANDONG GETTOP ACOUSTIC

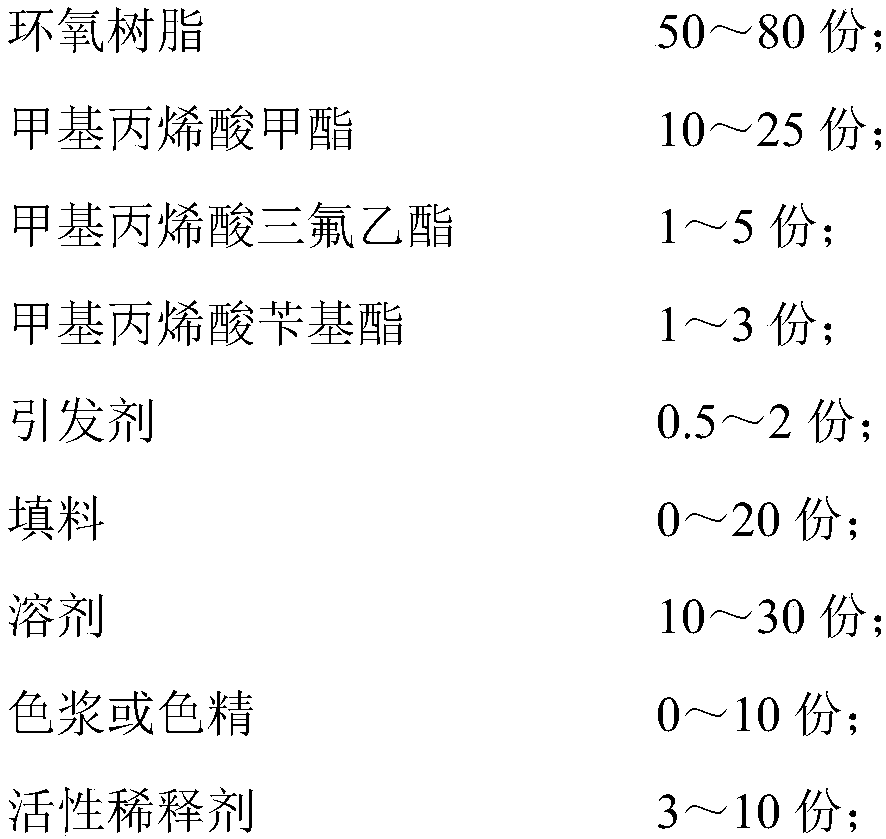

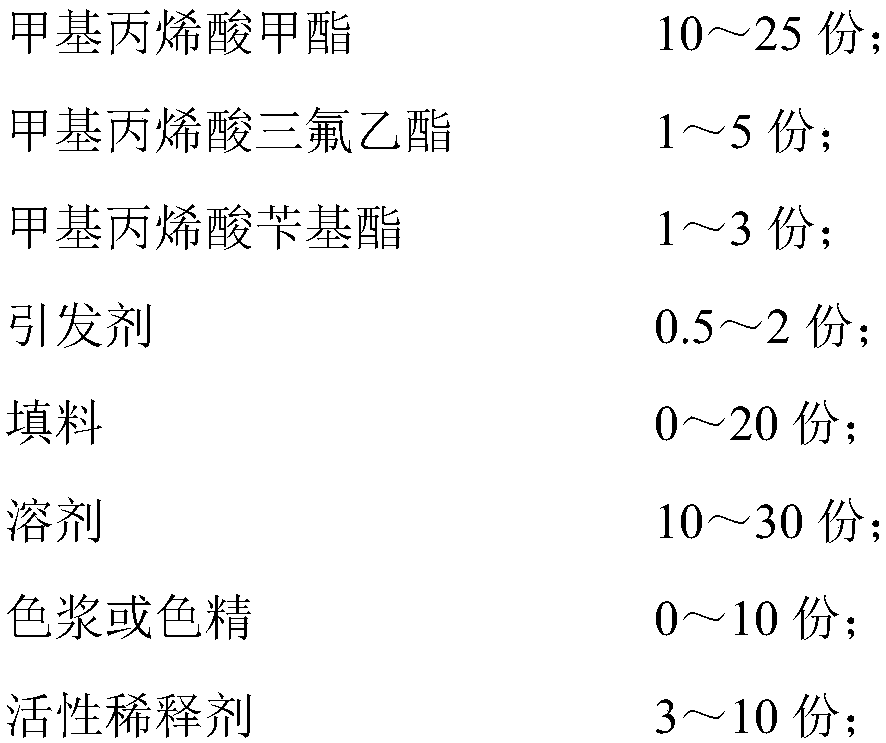

Preparation method of special epoxy resin paint for wind power blades resistant to salt spray

ActiveCN103666196BGood compatibilityImprove adhesionAnti-corrosive paintsEpoxy resin coatingsPolymer scienceMeth-

The invention relates to a preparation method of a special salt spray resistance epoxy resin paint for a wind power blade and belongs to the technical field of coatings. The preparation method comprises the following steps: taking epoxy resin, acrylic resin, amino resin, rosin modified maleic acid resin, polystyrene latex, dimethylolpropionic acid, methyl methacrylate, tert-butyl perbenzoate, polyethylene wax, alcohol nitrocotton, butyl acetate and ethylene glycol butyl ether for uniformly mixing in a mixer; then adding a thickener and a dispersant and uniformly mixing in the mixer;adding a nonionic surfactant, a pigment and packing, uniformly mixing in the mixer, grinding to the fineness of below 20mum and packaging. The epoxy resin paint provided by the invention has good compatibility to the wind power blade made of an epoxy resin material, has a high adhesive force which can reach 1 grade, has good salt spray corrosion resistance and is suitable for coating the marine wind power blade.

Owner:南通市通州区五接农业机电管理站有限公司

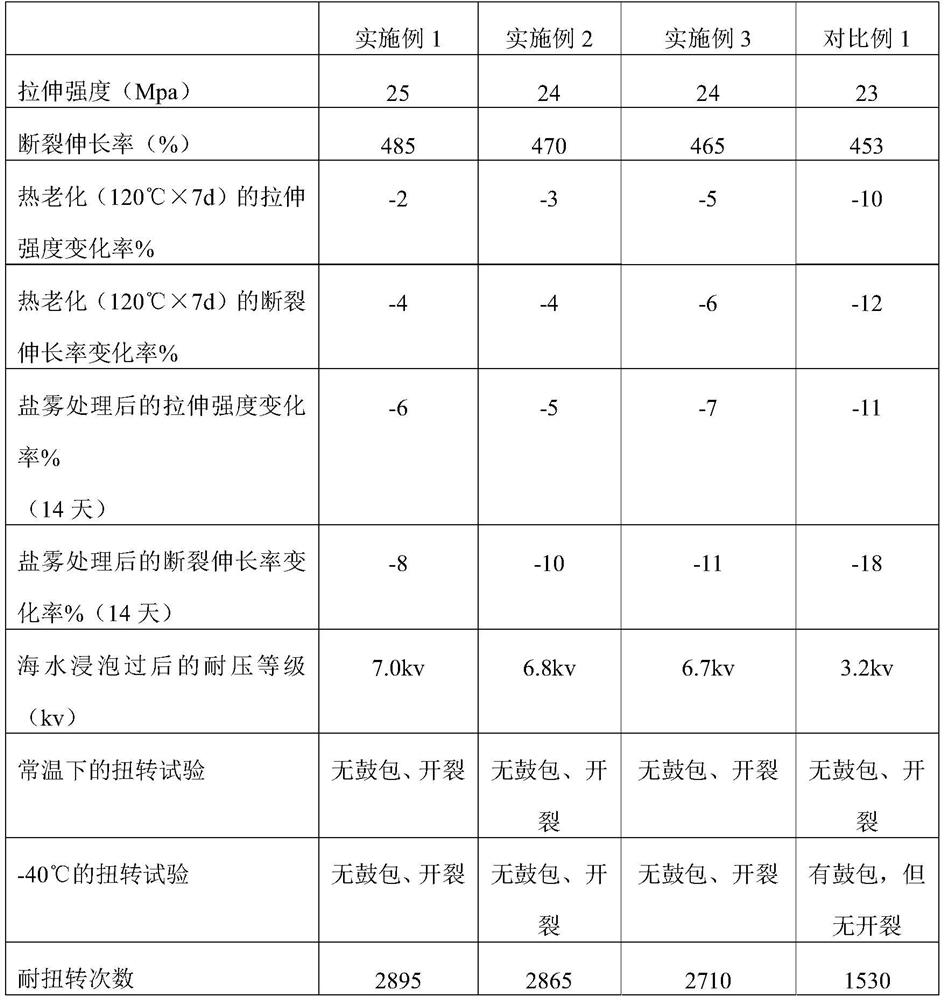

Salt-corrosion-resistant torsion-resistant control cable for ocean wind power

PendingCN112442230AImprove heat aging resistanceGood resistance to salt spray corrosionPlastic/resin/waxes insulatorsEngineeringFire retardant

The invention relates to the technical field of cable materials, in particular to a salt-corrosion-resistant torsion-resistant control cable for ocean wind power and a preparation method of the salt-corrosion-resistant torsion-resistant control cable. The cable is composed of an ethylene copolymer, maleic anhydride grafted EVA, magnesium oxide, a reinforcing agent, a silane coupling agent, a lubricant, a flame retardant and modified potassium hexatitanate whiskers. The cable provided by the invention has relatively good performances in the aspects of thermal aging resistance, salt spray corrosion resistance, seawater corrosion resistance and the like, and can well adapt to a complex climate environment where an ocean wind power facility is located. The cable has excellent torsion resistance, the number of times of torsion resistance is higher than 2500, and torsion at normal temperature or low temperature has no obvious influence on the material of the cable.

Owner:ANHUI HUININGELECTRIC INSTR & APPLIANCE GRP

A kind of marine high-strength tear-resistant rubber material and preparation method thereof

The invention relates to the field of polymer materials, in particular to a high-strength tear-resistant rubber material for ships and a preparation method thereof, comprising the following components: natural rubber, epoxidized natural rubber, aminated solution-polymerized styrene-butadiene rubber, liquid polyisocyanate Pentadiene rubber, epoxidized butadiene rubber, coupling agent modified one-dimensional carbon nanomaterials, white carbon black, carbon black, zinc oxide, additives, the rubber material prepared by the present invention has good mechanical properties, tensile High tensile strength and tear resistance, good salt spray corrosion resistance, and low density, suitable for making marine rubber parts.

Owner:湖南弘辉科技有限公司

No-clean antirust material capable of being integrally stripped or removed by heating, and preparation and application thereof

ActiveCN113845809AReduce VOC emissions and chemical solvent hazardsGood resistance to salt spray corrosionShellac coatingsWax coatingsSolventEmulsion

The invention belongs to the technical field of novel coating layer materials, and discloses a no-clean antirust material capable of being integrally stripped or removed by heating, a preparation method and application thereof. The preparation method comprises the following steps: mixing and homogenizing a waxy substance and a part of an alkane solvent to obtain an emulsion A; adding an elastic resin into the other part of the alkane solvent, adding an antirust agent and an interface treating agent under a stirring condition, and stirring until the antirust agent and the interface treating agent are completely dissolved to obtain a resin solution B; and mixing and homogenizing the emulsion A and the resin solution B, then adding a surfactant and a defoaming agent, homogenizing and stirring, and filtering to obtain the no-clean antirust material capable of being integrally stripped or removed by heating. According to the no-clean antirust material, the specific elastic resin and the waxy substance are compounded, the film forming state after use is a semitransparent soft film, compared with an existing oil film or a brittle paint film, the film can be removed by tearing off the whole film or heating melting / volatilizing, no chemical solvent or cleaning agent is needed for removal, and VOC emission and chemical solvent harm are remarkably reduced.

Owner:山立欣业新材料(广东)有限公司

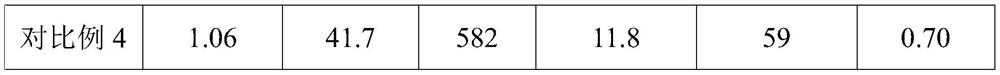

A kind of synthetic method and application of organosilicon modified polyurethane prepolymer

ActiveCN103848952BIncrease elasticityHigh strengthPolyureas/polyurethane adhesivesPolymer sciencePolyurethane adhesive

The invention relates to a substance formed by preliminary polymerization of a monomer, in particular to a synthesis method and application of an organosilicon-modified polyurethane prepolymer. It is made by using diphenylmethane diisocyanate (MDI100) successively with polyether diol (molecular weight 4000, commercially available brand D4000) and alkyl hydroxy silicone oil (take hydroxyl modified polydimethylsiloxane, commercially available brand BD-3253 (molecular weight: 3000) was polymerized to obtain a silicone-modified polyurethane-NCO-based prepolymer. It solves the problem of relatively poor salt spray corrosion resistance of polyurethane adhesives in the prior art, thereby realizing the technical requirements of marine adhesives.

Owner:YANTAI DARBOND TECH

A salt spray corrosion resistant electromagnetic shielding composite material and preparation method thereof

ActiveCN107325344BImprove corrosion resistanceGood electromagnetic shielding stabilityFiberCarbon fibers

The invention relates to the field of composite materials, and provides a salt-spray corrosion resistant electromagnetic shielding composite material and a preparation method of the salt-spray corrosion resistant electromagnetic shielding composite material. The electromagnetic shielding composite material mainly comprises raw rubber, conductive carbon black, expanded graphite and chopped carbon fibers, and the salt-spray corrosion resistant electromagnetic shielding composite material is finally subjected to vulcanization molding by using the mixing way of a double-roller open mill. The salt-spray corrosion resistant electromagnetic shielding composite material has high electromagnetic shielding effectiveness and salt-spray corrosion resistance, and excellent comprehensive performances, is very suitable for being applied as a shielding material in the field of marine environments with higher requirements on the salt-spray corrosion resistance and shielding performances, and further has good market prospects.

Owner:QINGDAO UNIV OF SCI & TECH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com