Wear-resistant paint applied to surface coating of metal bolt piece

A surface coating and wear-resistant coating technology, applied in the field of wear-resistant coatings, can solve the problems of poor surface varnish coatings, damage, and the paint layer is not smooth and smooth, and achieves good dispersion, good resistance to salt spray corrosion, and excellent adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

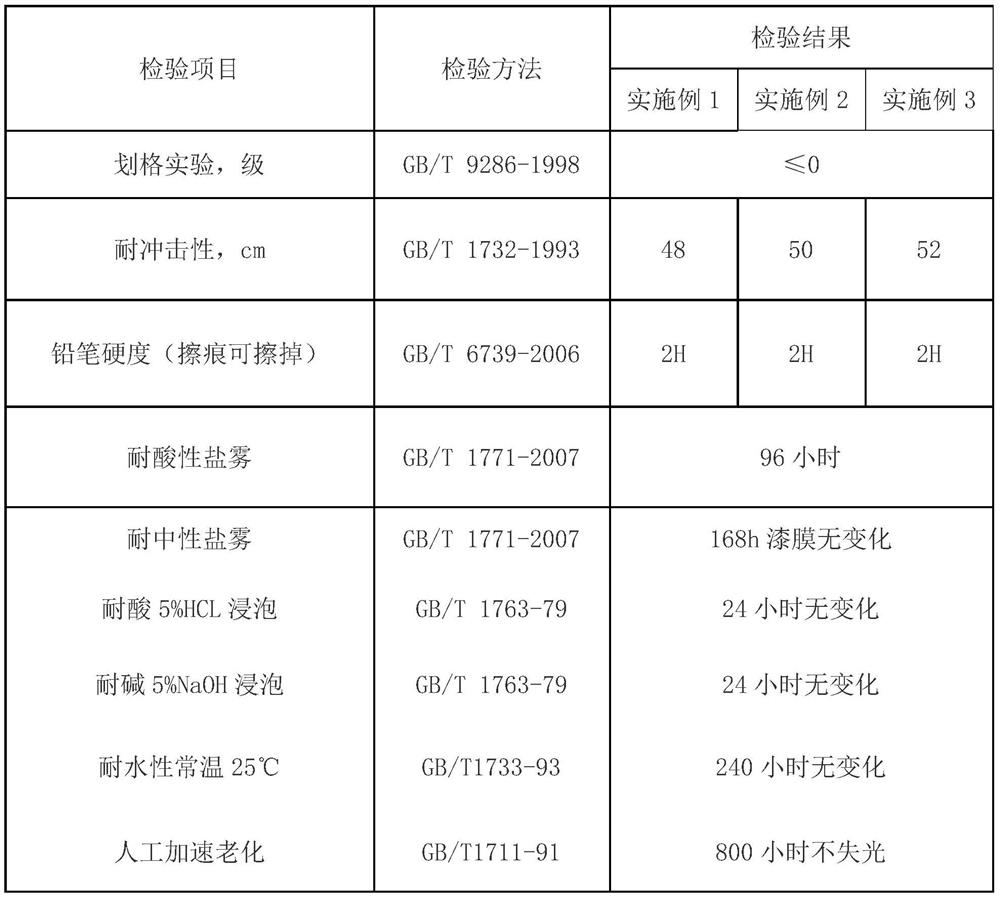

Embodiment 1

[0014] A wear-resistant coating applied to the surface coating of metal bolts, comprising the following components by weight: the wear-resistant coating applied to the surface coating of metal bolts consists of the following components by weight: methyl ether 30 parts of high imino melamine resin emulsion, 30 parts of acrylic resin emulsion, 2.5 parts of hydrochloric acid solution, 20 parts of sodium chloride, 1.8 parts of stannous chloride, 0.8 parts of hydroquinone, 14 parts of water, 0.6 parts of leveling agent , 0.5 parts of modified polydimethylsiloxane, and 8 parts of film-forming aids.

Embodiment 2

[0016] A wear-resistant coating applied to the surface coating of metal bolts, comprising the following components by weight: the wear-resistant coating applied to the surface coating of metal bolts consists of the following components by weight: methyl ether 35 parts of high imino melamine resin emulsion, 35 parts of acrylic resin emulsion, 2.6 parts of hydrochloric acid solution, 22 parts of sodium chloride, 1.8 parts of stannous chloride, 0.7 parts of hydroquinone, 12 parts of water, 0.7 parts of leveling agent , 0.6 parts of modified polydimethylsiloxane, and 8 parts of film-forming aids.

Embodiment 3

[0018] A wear-resistant coating applied to the surface coating of metal bolts, comprising the following components by weight: the wear-resistant coating applied to the surface coating of metal bolts consists of the following components by weight: methyl ether 40 parts of high imino melamine resin emulsion, 40 parts of acrylic resin emulsion, 3 parts of hydrochloric acid solution, 23 parts of sodium chloride, 1.9 parts of stannous chloride, 1 part of hydroquinone, 10 parts of water, 0.8 parts of leveling agent , 0.6 parts of modified polydimethylsiloxane, and 10 parts of film-forming aids.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com