Martensite stainless steel and preparation method thereof

A technology of martensitic stainless steel and ferrite, applied in the field of iron and steel metallurgy, to achieve the effect of excellent comprehensive mechanical properties and good salt spray corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Another technical solution of the present invention is to provide the preparation method of the martensitic stainless steel, which includes the following steps: smelting molten steel with the chemical composition, casting, hot rolling, and annealing to obtain it.

[0044] Among them, hot rolling is a key step. In the present invention, the steel billet is heated to 1050-1250°C for soaking, which can ensure that a single austenite phase can be obtained after soaking; hot rolling is carried out at a temperature range above 850°C, which can ensure that the austenite single phase of the above-mentioned stainless steel is formed during the hot rolling process. interval.

[0045] The martensitic stainless steel of the present invention is a martensite structure after hot rolling, and the martensite is transformed into a structure of ferrite + carbide after annealing, and has excellent drawing performance, hot top forging performance, machinability and salt resistance Fog cor...

Embodiment 1

[0046] Embodiment 1 Preparation of martensitic stainless steel of the present invention

[0047] The mass fraction of smelting chemical composition is C: 0.12%, Si=0.41%, Mn=0.39%, P=0.015%, S=0.002%, Ni=0.30%, Cr=13.5%, Cu=0.08%, V=0.12% , Al=0.015%, N=0.016% and the balance is Fe, (KFF=9.1, Cr+2.6*V-11*C-7*N=12.4) stainless steel, poured into a square billet of 200×200mm; The cast slab is heated to 1080°C for soaking, the rolling start temperature is 1050°C, hot rolled to a φ32mm round bar, and the final rolling temperature is 920°C; the steel bar is heated to 860°C and kept for 8 hours, the furnace is cooled to 300°C, and air cooled to room temperature.

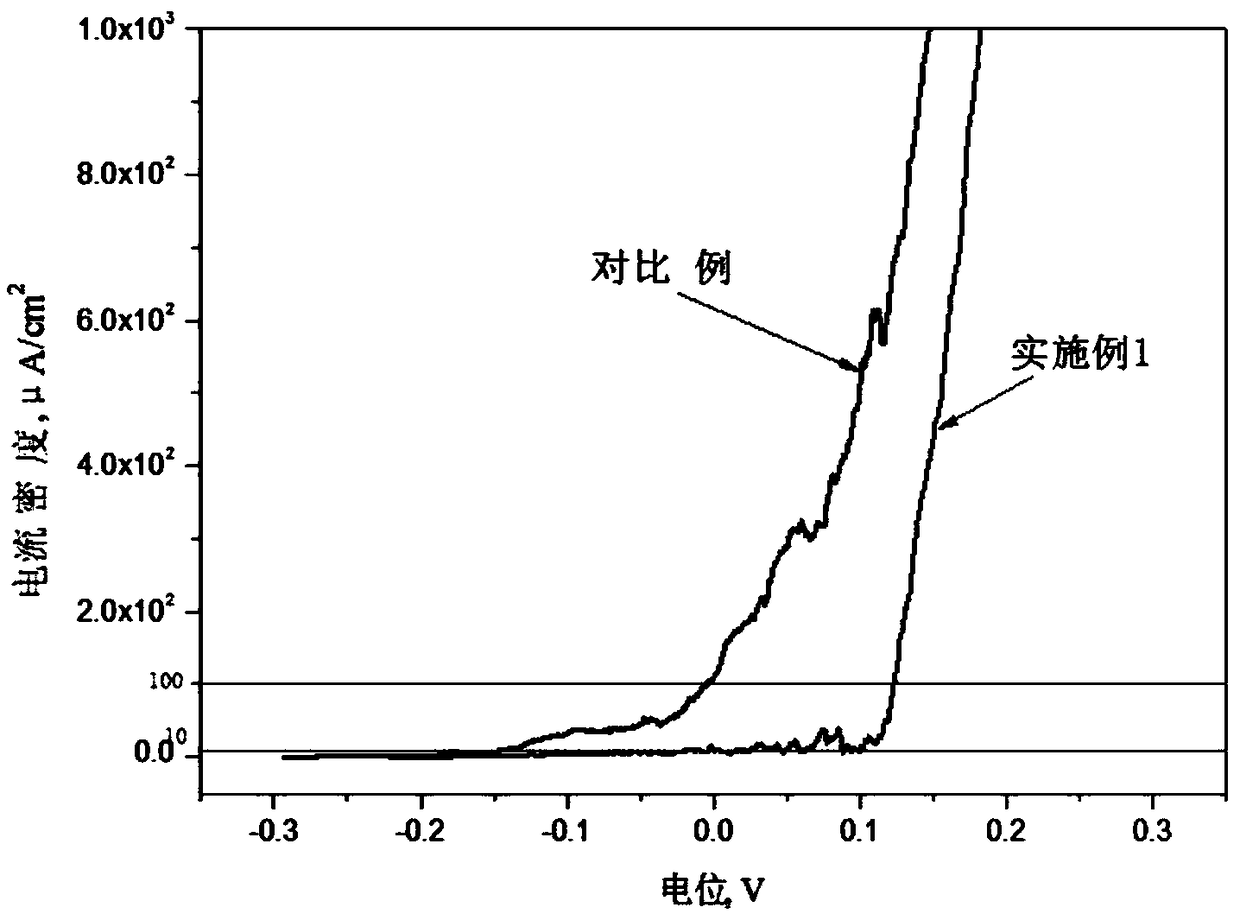

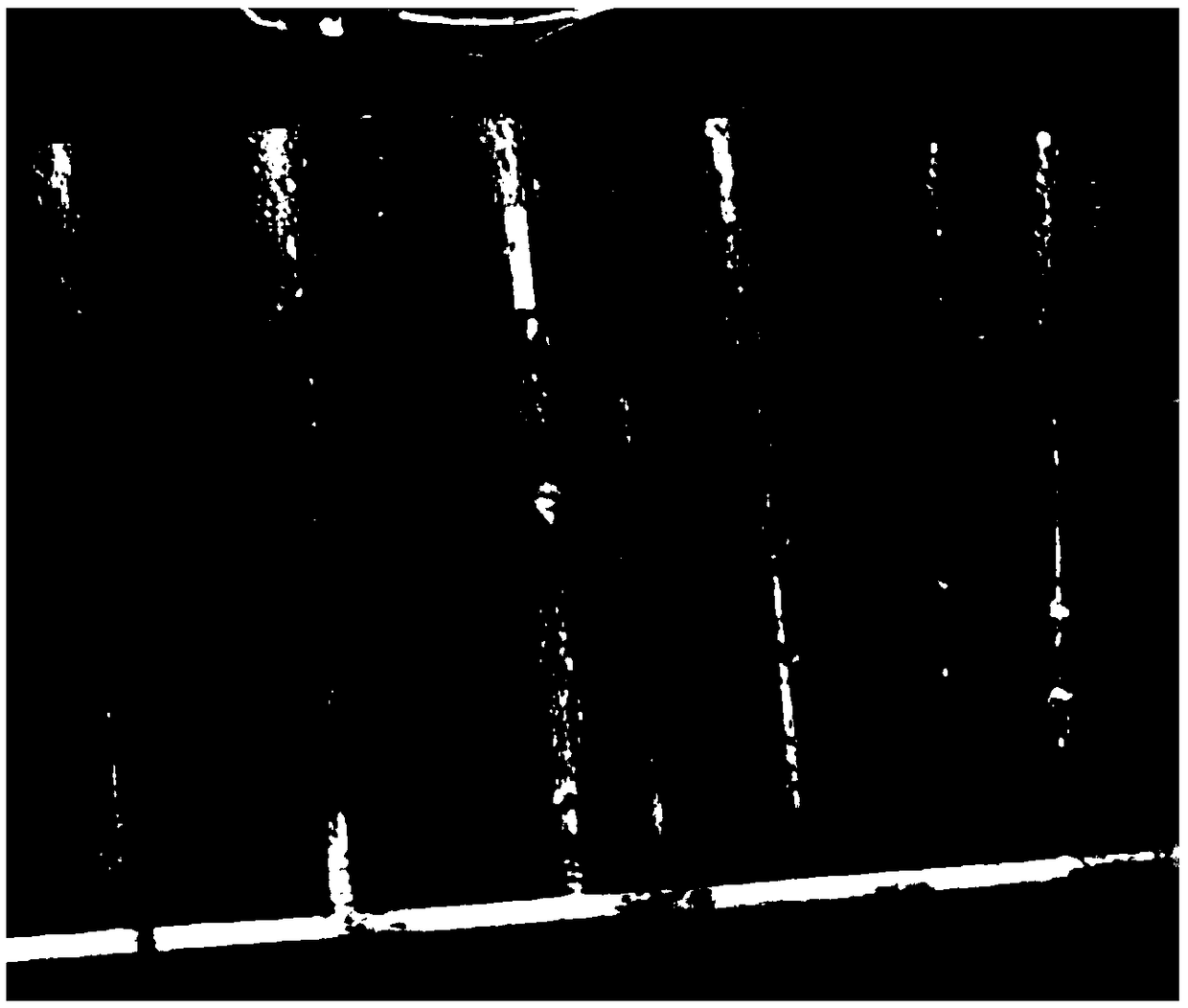

[0048] Brinell hardness of annealed steel rod HB=178; pitting potential E' b100 =122mV, see figure 1 , wherein the comparison example is 12Cr13 martensitic stainless steel; the surface is in the state of car polish, and there is no rust after 72 hours of neutral salt spray test, see figure 2 .

Embodiment 2

[0049] Embodiment 2 Preparation of martensitic stainless steel of the present invention

[0050] The mass fraction of smelting chemical composition is C: 0.25%, Si=0.36%, Mn=0.68%, P=0.020%, S=0.004%, Ni=0.23%, Cr=14.8%, Cu=1.5%, V=0.6% , Al=0.006%, N=0.004% balance is Fe, (KFF=6.9, Cr+2.6*V-11*C-7*N=13.6) stainless steel, poured into a square billet of 200×200mm; The cast slab is heated to 1250°C for soaking, the rolling start temperature is 1180°C, hot rolled to a φ60mm round bar, and the final rolling temperature is 980°C; the steel bar is heated to 830°C and kept for 10 hours, the furnace is cooled to 300°C, and air cooled to room temperature.

[0051] Brinell hardness of annealed steel bar HB=191; pitting potential E' b100 =127mV, the surface is in the state of car polish, and no rust occurs after 72 hours of neutral salt spray test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com