Preparation method of waterborne epoxy soybean oil modified epoxy-ester anticorrosive paint

A technology of epoxidized soybean oil and water-based epoxy, which is applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problem that salt spray resistance cannot meet the requirements of cars, reduce resin cross-linking active points, and cross-linking Density reduction and other problems, to achieve excellent salt spray corrosion resistance, excellent mechanical properties, good construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

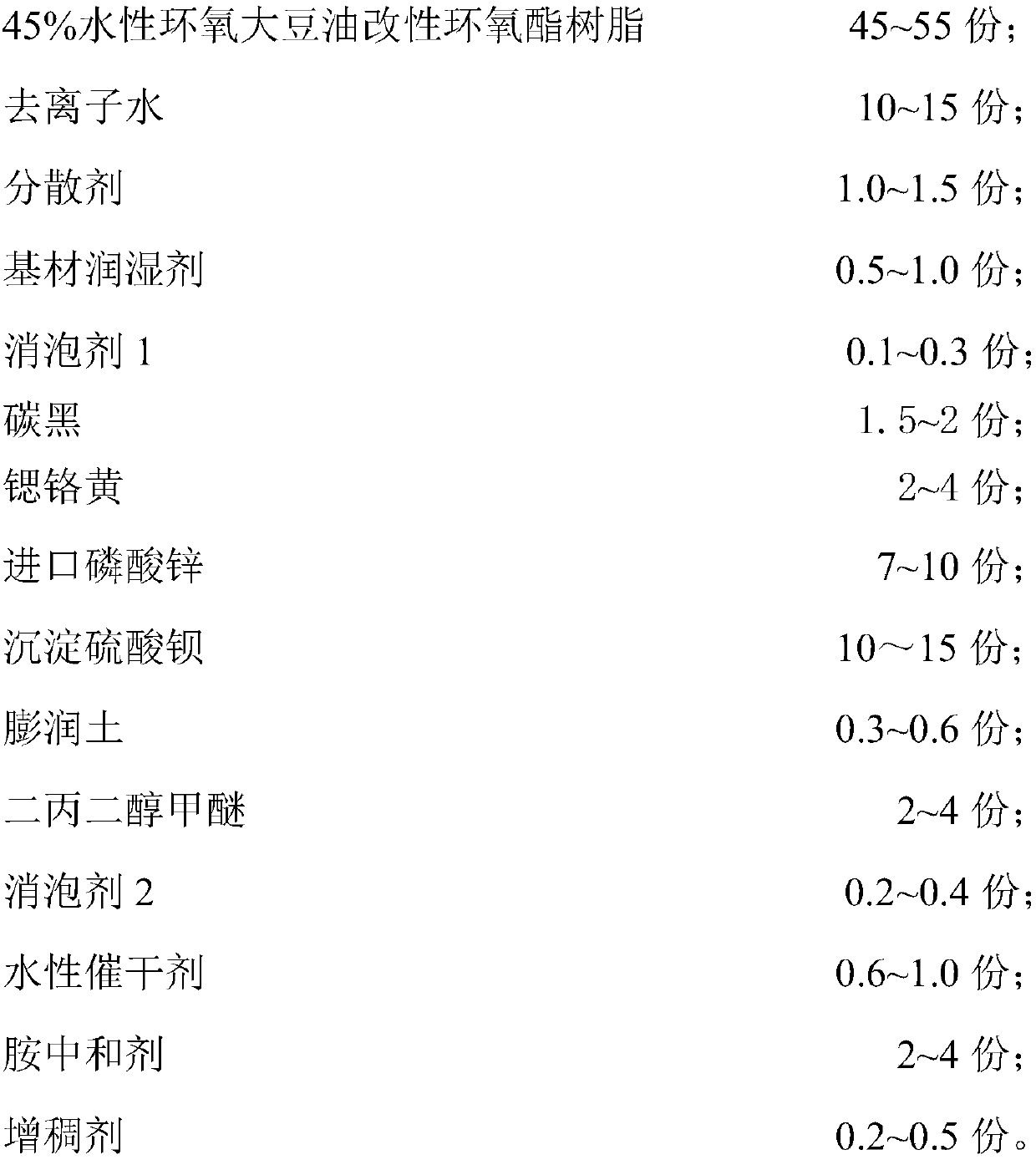

Examples

preparation example Construction

[0039] The preparation method of water-based epoxy soybean oil modified epoxy ester anticorrosion coating of the present invention may further comprise the steps:

[0040] (1) Preparation of epoxy soybean oil modified epoxy ester resin:

[0041]1) Synthesis of resin: E-44 epoxy resin with a mass fraction of 15 to 20 parts, 20 to 30 parts of dehydrated ricinoleic acid, 5 to 10 parts of maleic anhydride and 16 to 28 parts of ethylene glycol butylene Measure 5-10 parts of ether into a four-necked flask, gradually raise the temperature to 150°C, and keep it warm for 30 minutes. After the maleic anhydride is completely dissolved, pass in N 2 , start stirring, and then rapidly raise the temperature to 220-240°C and keep it for 2-3 hours. After the detection of acid value reaches 5-10mgKOH / g, drop to 100°C, add 10-15 parts of epoxidized soybean oil, and then dropwise add 5-10 acrylic acid, 3-8 parts methacrylic acid, 0.5-0.8 parts triphenylphosphine catalyst, 0.05-0.2 parts hydroxya...

Embodiment 1

[0051] (1) Preparation of 45% water-based epoxy soybean oil modified epoxy ester resin:

[0052] 1) Synthesis of resin: Add 15 parts of E-44 epoxy resin, 30 parts of dehydrated ricinoleic acid, 5 parts of maleic anhydride, and 5 parts of ethylene glycol butyl ether into a four-necked flask, and gradually heat up To 150°C, keep warm for 30min, after the maleic anhydride is completely dissolved, pass N 2 , start stirring, and then rapidly raise the temperature to 220°C and keep it for 3 hours. After the acid value reaches 10mgKOH / g, drop to 100°C, add 15 parts of epoxy soybean oil, then dropwise add 8 parts of acrylic acid and 3 parts of methacrylic acid , 0.8 parts of triphenylphosphine catalyst, 0.2 parts of the mixture of hydroxyanisole polymerization inhibitor, gradually warming up to 110 ° C, after 1 hour of insulation esterification, the acid value reached 40 mgKOH / g, cooling to 60 ° C, adding 18 part of ethylene glycol butyl ether solvent, adjust the solid content to 70±...

Embodiment 2

[0057] (1) Preparation of 45% water-based epoxy soybean oil modified epoxy ester resin:

[0058] 1) Synthesis of resin: Add 20 parts of E-44 epoxy resin, 27 parts of dehydrated ricinoleic acid, 8 parts of maleic anhydride, and 8 parts of ethylene glycol butyl ether into a four-necked flask, and gradually heat up To 150°C, keep warm for 30min, after the maleic anhydride is completely dissolved, pass N 2 , start stirring, then rapidly raise the temperature to 230°C and keep it for 2 hours. After the acid value reaches 10mgKOH / g, drop to 100°C, add 12 parts of epoxy soybean oil, then dropwise add 5 parts of acrylic acid and 4.3 parts of methacrylic acid , 0.5 parts of triphenylphosphine catalyst, 0.2 parts of hydroxyanisole polymerization inhibitor mixture, gradually warming up to 110 ° C, after 2 hours of heat preservation esterification, the acid value reached 30 mgKOH / g, cooling to 50-60 ° C, adding 15 parts of ethylene glycol butyl ether solvent, adjust the solid content to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com