Salt-corrosion-resistant torsion-resistant control cable for ocean wind power

A control cable and torsion-resistant technology, applied in circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of lack of a torsion-resistant control cable preparation method, the torsion resistance performance cannot meet the demand, and the weather resistance performance is poor. Excellent torsion resistance, low production cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

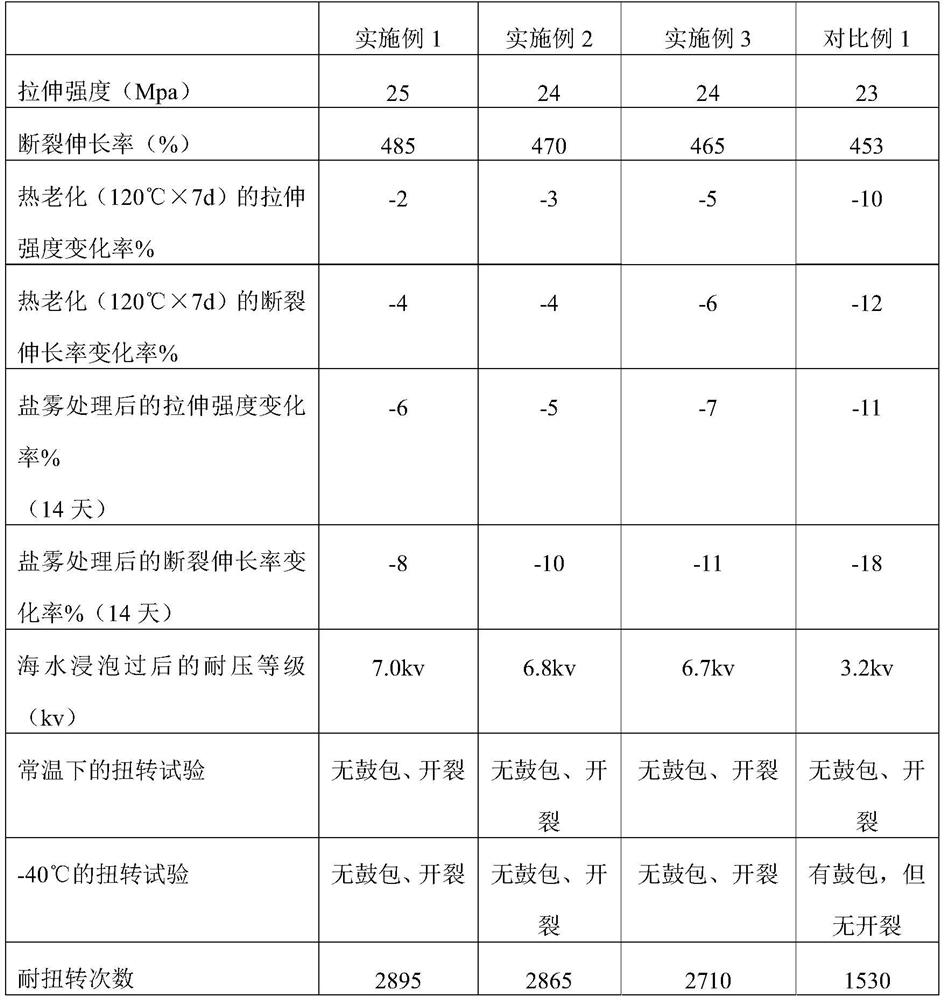

Examples

Embodiment 1

[0022] Concrete raw material is weighed by table 1, and step preparation step is as follows:

[0023] (1) Mix and dissolve the silane coupling agent KH550 and ethanol at a mass ratio of 1:15 to obtain a solution; mix potassium hexatitanate whiskers with ethanol at a mass ratio of 1:10, and ultrasonically disperse to obtain a suspension; Add the solution dropwise to the suspension with stirring, react at 70°C for 2 hours after the dropwise addition, then filter and dry the reaction solution to obtain the modified potassium hexatitanate whisker; among them, the silane coupling agent KH550 The mass ratio of potassium hexatitanate whiskers is 1:20;

[0024] (2) Add EVA, EEA, maleic anhydride grafted EVA, magnesium oxide, calcium carbonate, carbon black, silane coupling agent KH560, silane coupling agent KH570, and microcrystalline paraffin into the high-speed mixer, heat to 80°C, Mix for 20 minutes;

[0025] (3) Add aluminum hydroxide, aluminum hypophosphite, antimony trioxide, ...

Embodiment 2

[0028] (1) Mix and dissolve the silane coupling agent KH550 and ethanol at a mass ratio of 1:20 to obtain a solution; mix potassium hexatitanate whiskers with ethanol at a mass ratio of 1:15, and ultrasonically disperse to obtain a suspension; Add the solution dropwise to the suspension with stirring, react at 80°C for 1 hour after the dropwise addition, then filter and dry the reaction solution to obtain the modified potassium hexatitanate whisker; among them, the silane coupling agent KH550 The mass ratio of potassium hexatitanate whiskers is 1:30;

[0029] (2) Add EVA, EEA, maleic anhydride grafted EVA, magnesium oxide, calcium carbonate, carbon black, silane coupling agent KH560, silane coupling agent KH570, and microcrystalline paraffin into the high-speed mixer, heat to 85°C, Mix for 15 minutes;

[0030] (3) Add aluminum hydroxide, aluminum hypophosphite, antimony trioxide, and modified potassium hexatitanate whiskers to the mixture in step (2), continue mixing for 40 m...

Embodiment 3

[0033] (1) Mix and dissolve the silane coupling agent KH550 and ethanol at a mass ratio of 1:20 to obtain a solution; mix potassium hexatitanate whiskers with ethanol at a mass ratio of 1:15, and ultrasonically disperse to obtain a suspension; Add the solution dropwise to the suspension with stirring, react at 80°C for 2 hours after the dropwise addition, and then filter and dry the reaction solution to obtain the modified potassium hexatitanate whisker; among them, the silane coupling agent KH550 The mass ratio of potassium hexatitanate whiskers is 1:25;

[0034] (2) Add EVA, EEA, maleic anhydride grafted EVA, magnesium oxide, calcium carbonate, carbon black, silane coupling agent KH560, silane coupling agent KH570, and microcrystalline paraffin into the high-speed mixer, heat to 90°C, Mix for 20 minutes;

[0035] (3) Add aluminum hydroxide, aluminum hypophosphite, antimony trioxide, and modified potassium hexatitanate whiskers to the mixture in step (2), continue mixing for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com