Construction process of high-durability epoxy floor

A technology of epoxy flooring and construction technology, which is applied in the direction of anti-corrosion coatings, insulating layers, coatings, etc., can solve problems such as unsatisfactory industrial needs, uneven ground, slow curing at low temperature during construction, etc., and achieve good wear resistance, Good skid resistance, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

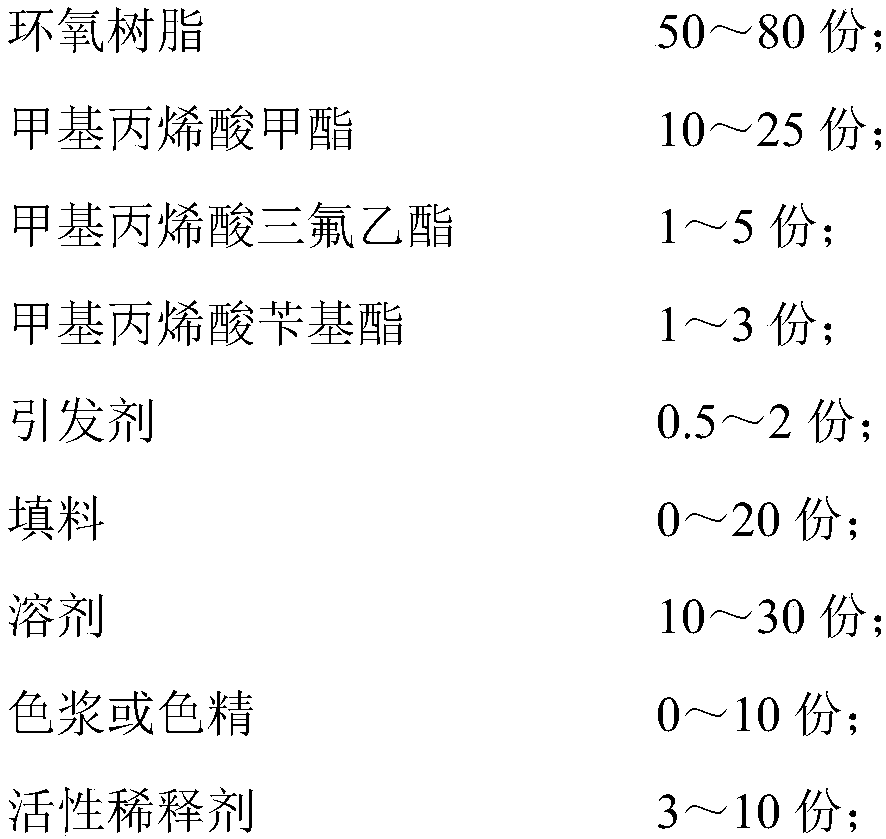

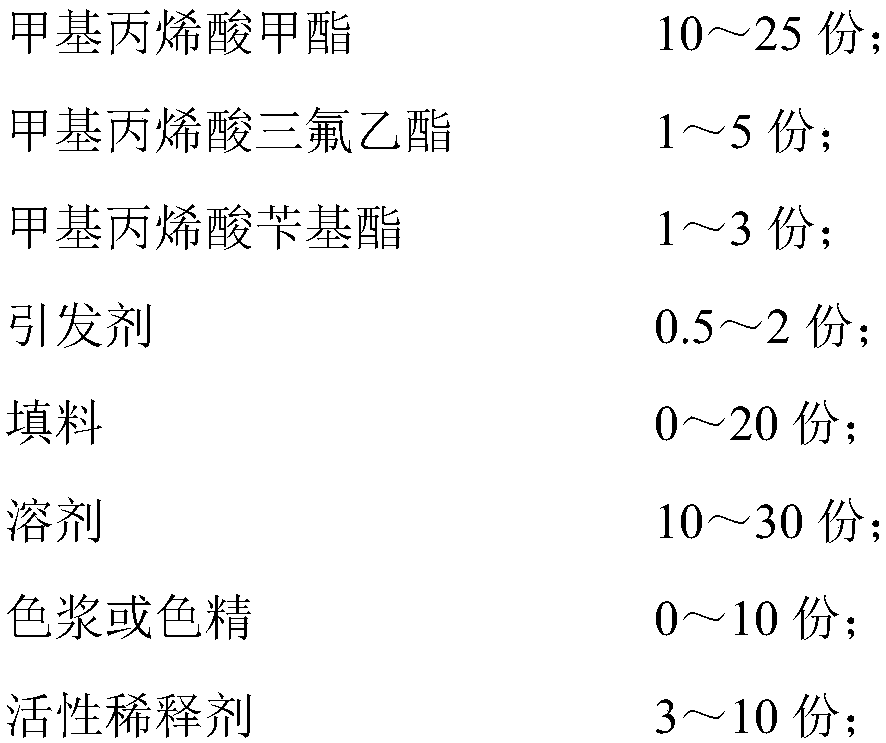

[0076] In a preferred embodiment, the preparation method of the first component at least includes the following steps:

[0077] Add epoxy resin, methyl methacrylate, trifluoroethyl methacrylate, benzyl methacrylate and solvent into the reaction kettle in corresponding parts by weight, stir evenly, and add initiator, then raise the reaction temperature to The temperature is as high as 75°C, and the stirring reaction is carried out for 2 to 5 hours to obtain the reaction product. After cooling to room temperature, the filler, the color paste, and the active diluent are added to the reaction product in sequence, and the first component is obtained after stirring evenly.

[0078] In a preferred embodiment, the first component also includes an auxiliary agent; the auxiliary agent is selected from: antioxidant, defoamer, flame retardant, ultraviolet absorber, leveling agent, wetting agent Any one or a mixture of dispersants, defoamers, heat stabilizers.

[0079] The antioxidants ma...

Embodiment 1

[0103] Embodiment 1 of the present invention provides a kind of high durability type epoxy floor, the construction technique of described high durability type epoxy floor, comprises the following steps at least:

[0104] (1) Treat the base: pave cement on the ground to obtain a cement base with a thickness of 50mm, and polish the cement to obtain the treated base;

[0105] (2) Laying the primer layer: coating the treated base layer with a thickness of 0.1mm for the primer layer;

[0106] (3) Laying the first glass fiber layer: laying one deck of glass fiber cloth on the primer layer, and coating the primer layer again on the glass fiber cloth after drying to obtain the first glass fiber layer;

[0107] (4) Lay the first epoxy mortar layer: uniformly mix the intermediate coating resin and quartz sand at a ratio of 1:5 to obtain epoxy mortar, and coat the epoxy mortar on the glass fiber layer to obtain the first epoxy mortar layer;

[0108] (5) Laying the second glass fiber lay...

Embodiment 2

[0138] Embodiment 2 of the present invention provides a kind of high durability type epoxy floor, the construction technology of described high durability type epoxy floor, comprises the following steps at least:

[0139] (1) Treat the base: pave cement on the ground to obtain a cement base with a thickness of 50mm, and polish the cement to obtain the treated base;

[0140] (2) Laying the primer layer: coating the treated base layer with a thickness of 0.1mm for the primer layer;

[0141] (3) Laying the first glass fiber layer: laying one deck of glass fiber cloth on the primer layer, and coating the primer layer again on the glass fiber cloth after drying to obtain the first glass fiber layer;

[0142] (4) Lay the first epoxy mortar layer: uniformly mix the intermediate coating resin and quartz sand at a ratio of 1:5 to obtain epoxy mortar, and coat the epoxy mortar on the glass fiber layer to obtain the first epoxy mortar layer;

[0143] (5) Laying the second glass fiber la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com