Preparation method of environment-friendly self-healing type titanium/zirconium/molybdenum conversion film on surface of aluminum alloy

A technology of aluminum alloy surface and conversion coating, applied in the direction of metal material coating process, etc., can solve the problems of light color of titanium/zirconium conversion coating, complex film formation mechanism, and corrosion resistance not as good as chromate. Corrosion resistance, reduced equipment investment, low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

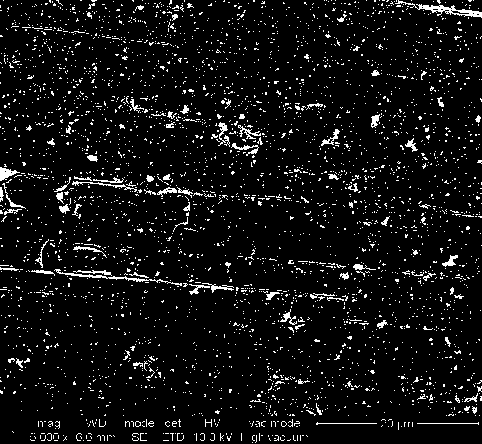

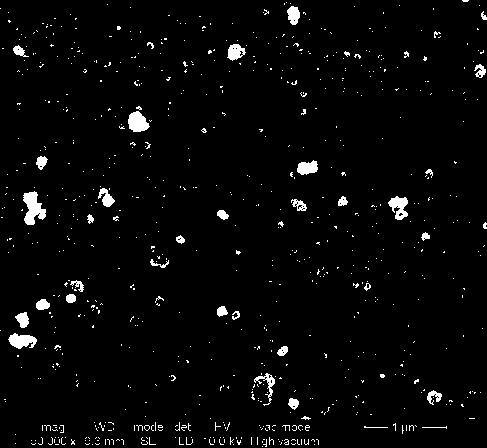

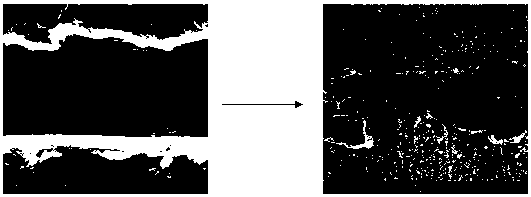

Image

Examples

Embodiment 1

[0032] A method for preparing an environment-friendly self-healing titanium / zirconium / molybdenum conversion film on the surface of an aluminum alloy, comprising the following steps:

[0033] Surface pretreatment of aluminum alloy specimens. First of all, sample preparation is carried out. An aluminum sheet sample with a size of 20mm×20mm×2mm is obtained from 6061 aluminum alloy on-line cutting. Each sample is punched at the corner, and the surface of the sample is polished to 1200 mesh with sandpaper, and rinsed with tap water. Blow dry and hang with thin wire over punched holes.

[0034] The 6061 aluminum alloy sample was suspended in industrial acid and soaked for 2 minutes to remove oil, rinsed with tap water, then soaked in mixed acid for 3 minutes for activation treatment, and rinsed with tap water. The composition of described industrial acid is 40g / L H 2 SO 4 , 15g / LH 3 PO 4 , 8g / L HF, 0.8g / L OP-10 emulsifier, the solvent is water, and the total volume of the indus...

Embodiment 2

[0041] A method for preparing an environment-friendly self-healing titanium / zirconium / molybdenum conversion film on the surface of an aluminum alloy, comprising the following steps:

[0042]Surface pretreatment of aluminum alloy specimens. First of all, prepare the sample. Cut the 6062 aluminum alloy on-line to obtain an aluminum sheet sample with a size of 20mm×20mm×2mm. Each sample is punched at the corner, and the surface of the sample is polished to 1200 mesh with sandpaper, and rinsed with tap water. Blow dry and hang with thin wire over punched holes.

[0043] The 6062 aluminum alloy sample was suspended in industrial acid and soaked for 3 minutes to remove oil, rinsed with tap water, then soaked in mixed acid for 5 minutes for activation treatment, and rinsed with tap water. The composition of described industrial acid is 80g / L H 2 SO 4 , 30g / LH 3 PO 4 , 10g / L HF, 2.8g / L OP-10 emulsifier, the solvent is water, and the total volume of the industrial acid formed is 1...

Embodiment 3

[0049] A method for preparing an environment-friendly self-healing titanium / zirconium / molybdenum conversion film on the surface of an aluminum alloy, comprising the following steps:

[0050] Surface pretreatment of aluminum alloy specimens. First of all, prepare the sample. Cut the 6063 aluminum alloy on-line to obtain an aluminum sheet sample with a size of 20mm×20mm×2mm. Each sample is punched at the corner, and the surface of the sample is polished to 1200 mesh with sandpaper, and rinsed with tap water. Blow dry and hang with thin wire over punched holes.

[0051] The 6063 aluminum alloy sample was suspended in industrial acid and soaked for 3 minutes to remove oil, rinsed with tap water, then soaked in mixed acid for 5 minutes for activation treatment, and rinsed with tap water. The composition of described industrial acid is 80g / L H 2 SO 4 , 30g / LH 3 PO 4 , 10g / L HF, 2.8g / L OP-10 emulsifier, the solvent is water, and the total volume of the industrial acid formed is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com