Modified silver powder conductive coating and preparation method thereof

A conductive coating and silver powder technology, applied in conductive coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of reduced chemical corrosion effectiveness, and achieve the effects of improving interface characteristics, increasing service life, and optimal service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

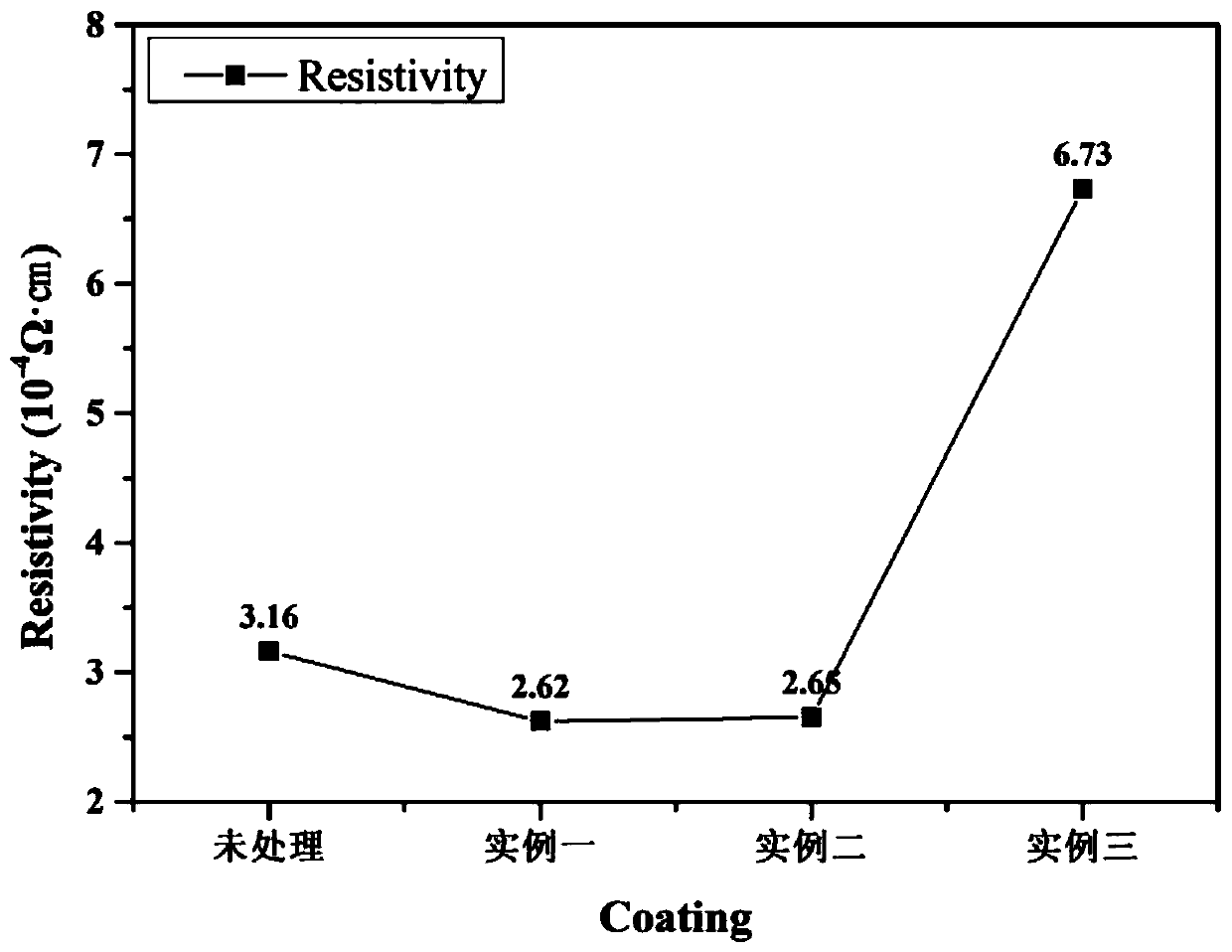

Embodiment 1

[0024] Step 1: In 150 parts by mass of absolute ethanol, add 0.3 parts by mass of dodecyl mercaptan, stir and dissolve evenly;

[0025] Step 2: Add 30 parts by mass of silver powder to the mixed solution obtained in step 1 to prepare a uniformly dispersed mixed solution;

[0026] Step 3: Put the mixed solution obtained in Step 2 into a water bath, and react at 60°C for 5 hours, during which a magnetic stirrer is used to continuously stir to make the solution fully react;

[0027] Step 4: After step 3 is completed, wait for the solution to cool down naturally, add absolute ethanol to wash by centrifugation for 3 times, and then vacuum-dry at 60°C for 4 hours to obtain modified silver powder;

[0028] Step 5: Weigh 3 parts by mass of epoxy resin component B and 15 parts by mass of butyl acetate, and stir until component B of epoxy resin is completely dissolved;

[0029] Step 6: Add the modified silver powder prepared in Step 4 to the solution prepared in Step 5, stir evenly, ad...

Embodiment 2

[0031] Step 1: In 150 parts by mass of absolute ethanol, add 0.9 parts by mass of dodecyl mercaptan, stir and dissolve evenly;

[0032] Step 2: Add 30 parts by mass of silver powder to the mixed solution obtained in step 1 to prepare a uniformly dispersed mixed solution;

[0033] Step 3: Put the mixed solution obtained in Step 2 into a water bath, and react at 40°C for 5 hours, during which a magnetic stirrer is used to continuously stir to make the solution fully react;

[0034] Step 4: After step 3 is completed, wait for the solution to cool down naturally, add absolute ethanol to wash by centrifugation for 3 times, and then vacuum-dry at 60°C for 4 hours to obtain modified silver powder;

[0035] Step 5: Weigh 3 parts by mass of epoxy resin component B and 15 parts by mass of butyl acetate, and stir until component B of epoxy resin is completely dissolved;

[0036] Step 6: Add the modified silver powder prepared in Step 4 to the solution prepared in Step 5, stir evenly, ad...

Embodiment 3

[0038] Step 1: In 150 parts by mass of absolute ethanol, add 0.9 parts by mass of dodecyl mercaptan, stir and dissolve evenly;

[0039] Step 2: Add 30 parts by mass of silver powder to the mixed solution obtained in step 1 to prepare a uniformly dispersed mixed solution;

[0040] Step 3: Put the mixed solution obtained in Step 2 into a water bath, and react at 60°C for 8 hours, during which a magnetic stirrer is used to continuously stir to make the solution fully react;

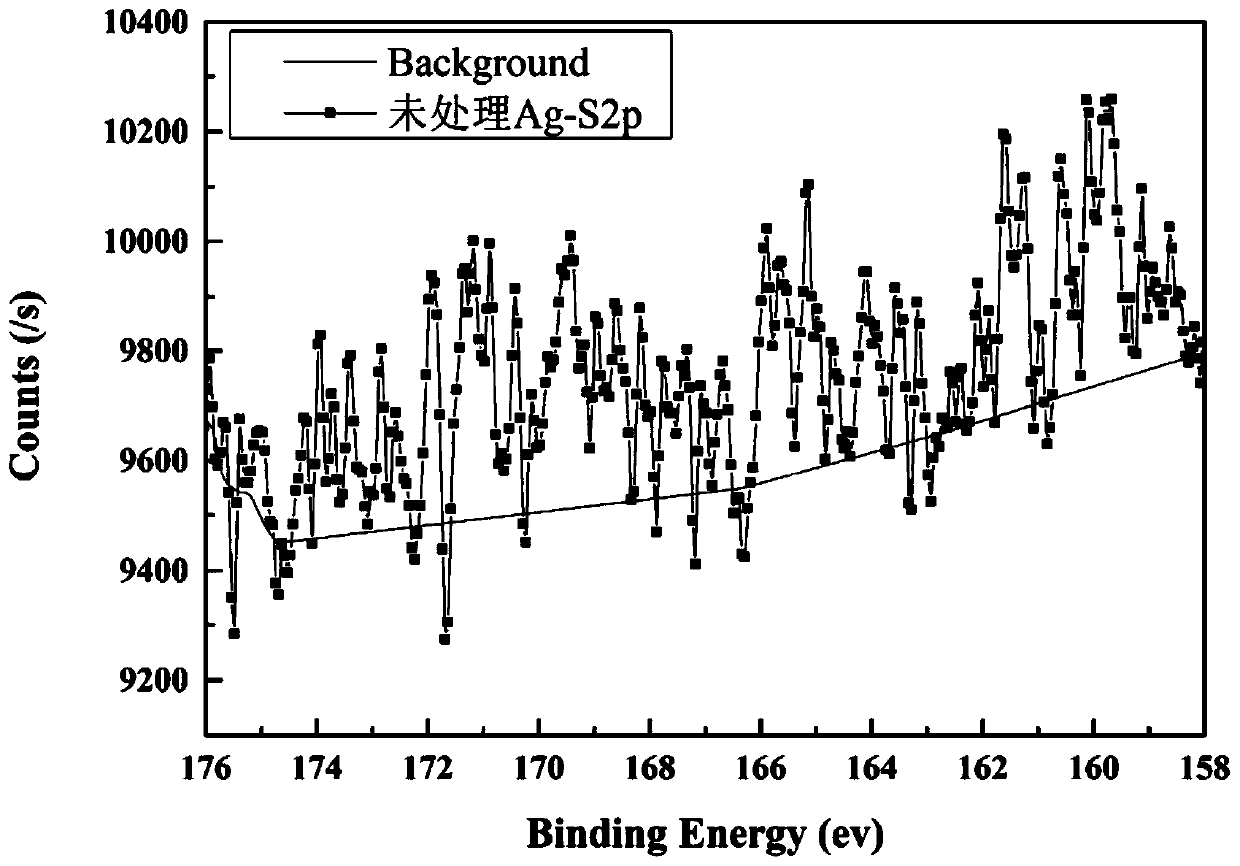

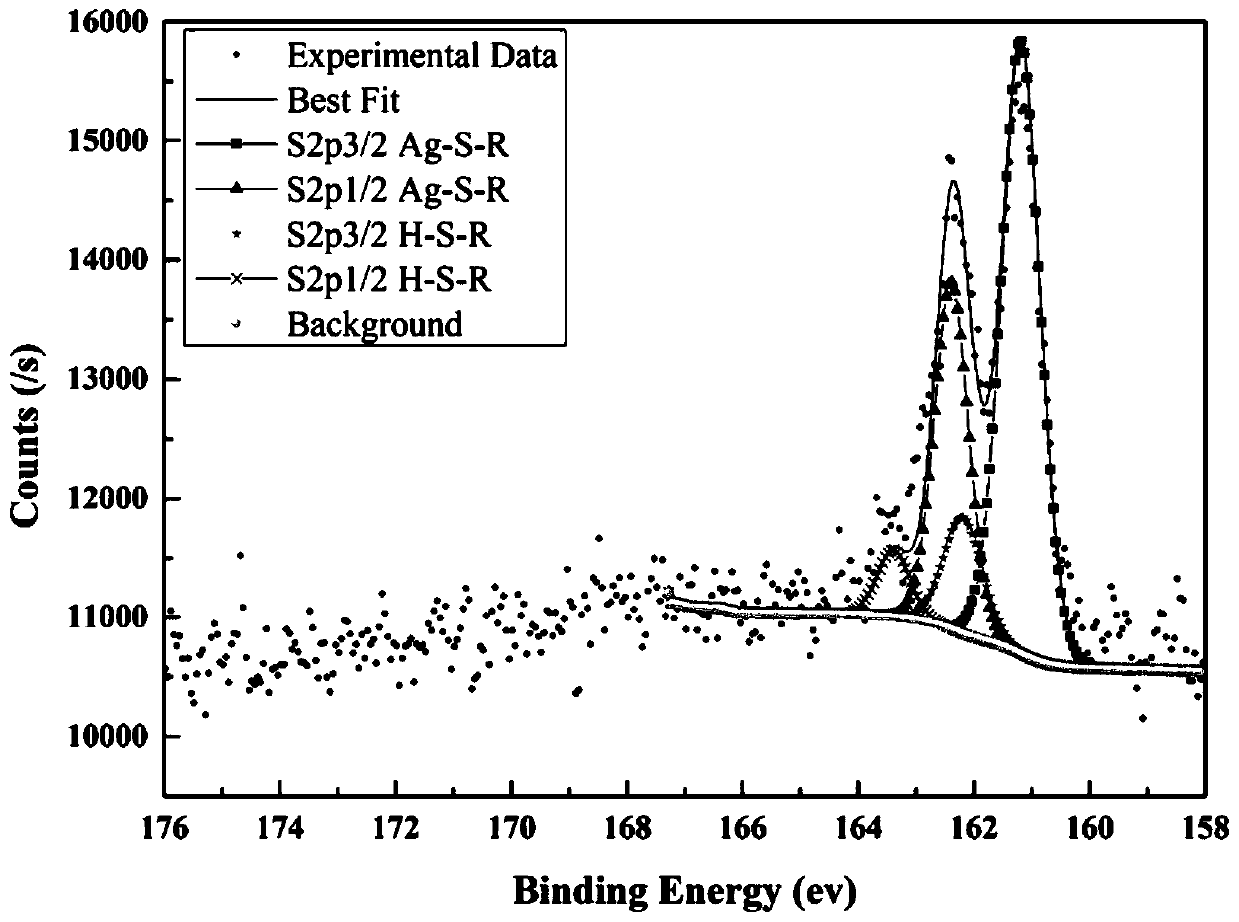

[0041] Step 4: After step 3 is completed, wait for the solution to cool down naturally, add absolute ethanol to wash by centrifugation for 3 times, and then vacuum-dry at 60°C for 4 hours to obtain modified silver powder; figure 2 It is the S2p discrete diagram of the modified silver powder XPS obtained in Step 4 of Example 3, which shows that dodecyl mercaptan has been successfully grafted on the surface of the silver powder.

[0042] Step 5: Weigh 3 parts by mass of epoxy resin component B and 15 parts b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com