Non-chrome silver-based soldering flux and preparation method thereof

A solder, silver-based technology, applied in welding equipment, welding/cutting medium/material, welding medium, etc., can solve the problems of low strength and poor wettability of silver-free solder-free solder, and achieve spreading performance and plasticity. Good, reduce pollution, avoid the effect of harm to health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

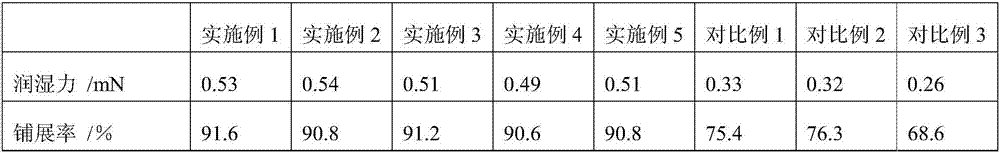

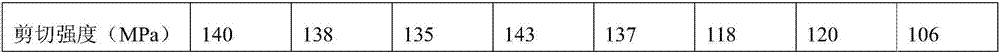

Examples

Embodiment 1

[0027] A silver-free based solder, in weight percentage, comprises: Ag39, Zn29.5, Sn2.5, Ni1.3, In0.1, Co0.05, graphene 0.01, and the balance is Cu and inevitable impurities.

[0028] The preparation method of the silver-free base solder in the present embodiment includes the following steps:

[0029] (1) prepare the alloy of the raw material except Graphene according to the proportion, and the prepared alloy is pulverized to 100-150 mesh for subsequent use;

[0030] (2) Graphene was added to alcohol, treated with ultrasonic, ultrasonic power 150W, frequency 80kHz, time 2h;

[0031] (3) adding the ultrasonically treated graphene alcohol solution and alloy powder to a high-energy ball mill, 150 r / min, temperature 150 degrees, and grinding for 10 min;

[0032] (4) drying the ground graphene and alloy powder mixture;

[0033] (5) the mixture after drying is put into the grinding tool, extruded, the pressure is 80MPa, and the holding time is 15min;

[0034] (6) Sinter the forme...

Embodiment 2

[0036] A silver-free based solder, in weight percentage, comprises: Ag40, Zn30, Sn3, Ni1.5, In0.15, Co0.08, graphene 0.015, and the balance is Cu and inevitable impurities.

[0037] The preparation method of the silver-free base solder in the present embodiment includes the following steps:

[0038] (1) prepare the alloy of the raw material except Graphene according to the proportion, and the prepared alloy is pulverized to 100-150 mesh for subsequent use;

[0039] (2) adding graphene to alcohol, and ultrasonically treating it with ultrasonic power of 180W, frequency of 90kHz, and time of 2.5h;

[0040] (3) adding the ultrasonically treated graphene alcohol solution and alloy powder into a high-energy ball mill, 180 r / min, temperature 180 degrees, and grinding for 12 min;

[0041] (4) drying the ground graphene and alloy powder mixture;

[0042] (5) the mixture after drying is put into the grinding tool, extruded, the pressure is 85MPa, and the holding time is 18min;

[004...

Embodiment 3

[0045] A silver-free based solder, in terms of weight percentage, comprising: Ag41.0, Zn31.5, Sn3.5, Ni1.7, In0.2, Co0.1, graphene 0.02, and the remainder is Cu and unavoidable impurities.

[0046] The preparation method of the silver-free base solder in the present embodiment includes the following steps:

[0047] (1) prepare the alloy of the raw material except Graphene according to the proportion, and the prepared alloy is pulverized to 100-150 mesh for subsequent use;

[0048](2) Graphene is added to alcohol, and ultrasonic treatment is used, ultrasonic power is 200W, frequency is 100kHz, and time is 3h;

[0049] (3) adding the ultrasonically treated graphene alcohol solution and alloy powder into a high-energy ball mill, at 200 r / min, at a temperature of 200 degrees, and grinding for 15 min;

[0050] (4) drying the ground graphene and alloy powder mixture;

[0051] (5) the mixture after drying is put into the grinding tool, extruded, the pressure is 90MPa, and the hold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com